Overview

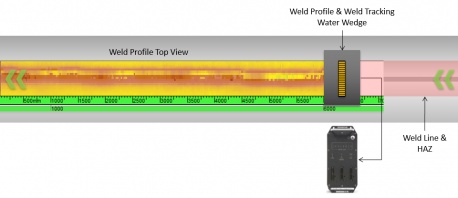

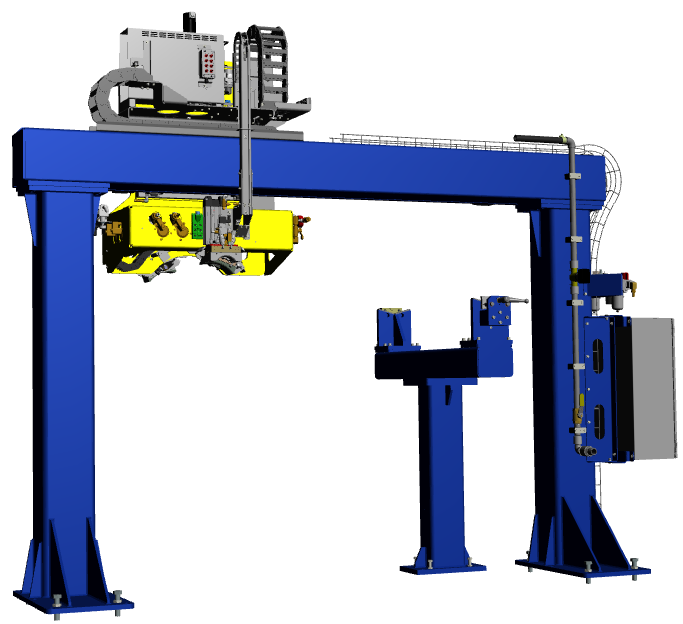

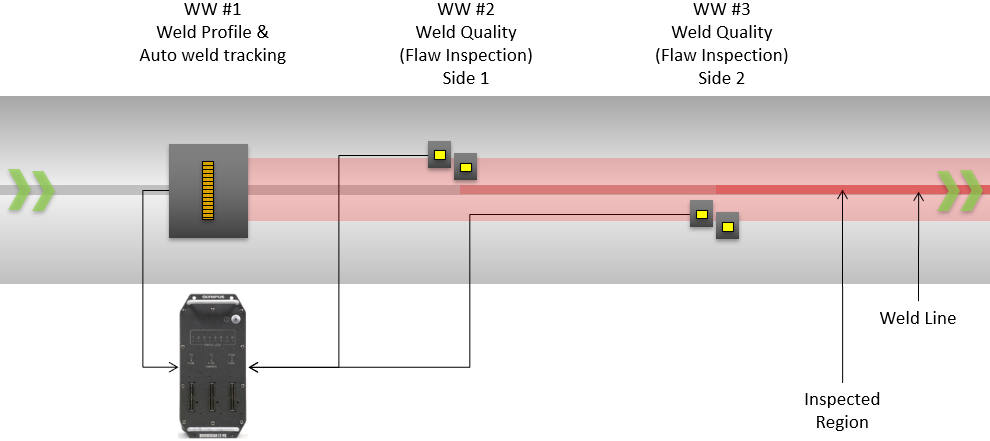

| ERW Solutions: In-Line ERW High-Temperature Inspection SystemFully Automated ERW Tube Process-ControlThe In-Line ERW High-Temperature Inspection System integrates into the production line between the weld cooling and annealing, where the pipe temperature is 100 °C (212 °F) or lower. A special self-cooling wedge combined with automatic alarms protect the phased array (PA) probe against excessive temperatures. Using conventional ultrasonic (UT) and PA technology, the system inspects the internal and external surfaces of the ERW seam and the heat-affected zone (HAZ) in pipes ranging from 60.3 mm to 508 mm (2.4 in. to 20 in.) OD. Automatic weld tracking technology connected to servomotor-driven mechanisms helps ensure coverage of the region of interest. The following typical defects are detected:

|

|---|

Strict Standard Compliance for OCTG Tube ManufacturersCompletely automated, the In-Line ERW High-Temperature System’s phased array probe tracks and records the weld profile and the UT probes detect flaws in the welded area using the automatic positioning. This turnkey system gives ERW pipe manufacturers the tools to meet the inspection requirements of international standards:

|

|

|---|

Software and Acquisition Unit

Phased Array Acquisition UnitThe QuickScan™ PA 32:256 module meets IP55 standards and is designed to easily integrate into industrial environments. Easy Setup and Data ManagementQuickView™ software makes it easy to configure the system and acquire and manage data. The results are merged and displayed to clearly differentiate between accepted and rejected tubes.

|  |

Real-Time Weld ProfilingQuickView software displays a complete weld profile view in real time without mechanical oscillation of the phased array probe.

|

Specifications

System Performance

| ||||||||||||||||||||||||||||