Artifacts recovered from archaeological excavations tell us a lot about our collective past, including the technology and methods used to create the objects. Consequently, artifacts can have significant cultural value. Some artifacts are fragile, so rather than display the original, museums will have a copy made and display that instead. And although an artifact’s knowledge and research value are paramount, its beauty and cultural significance can imbue an artifact with a monetary value, which makes them targets for forgeries. Knowing whether a researcher is dealing with a copy or the real thing is important, and industrial microscopes are a key tool to make this evaluation possible.

.jpg?rev=361E)

.jpg?rev=361E)

Industrial microscopes offer various features that help experts evaluate the authenticity of an artifact. Some forgeries are very good, making them hard to tell apart from genuine artifacts. Having a microscope with versatile imaging technologies and outstanding image quality are critical to enable experts to make a proper evaluation.

How to Tell a Real Artifact from a Forgery

One way experts evaluate potential forgeries is by studying markings and traces that were produced when artifacts were made. First, genuine artifacts from known excavations are examined with a microscope to understand how they were made. Experts examine markings that were left behind during the manufacturing process. Once they understand how the genuine artifact was made, potential forgeries can be examined and their markings compared with those found on the genuine artifacts. This enables an expert to evaluate whether the marks found on a potential forgery are consistent with what is expected for an object made during a certain time period.

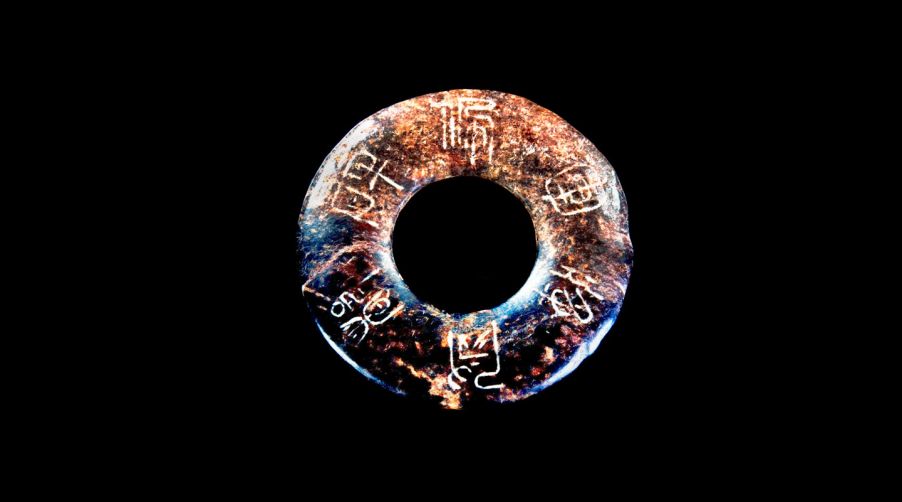

The example below shows genuine jade artifacts excavated from a site in China. Researchers studied them using a DSX1000 digital microscope to better understand the evolution of ancient mechanical processing. The microscope’s extended depth-of-field and 3D imaging technology were important to visualize fine details on the artifacts.

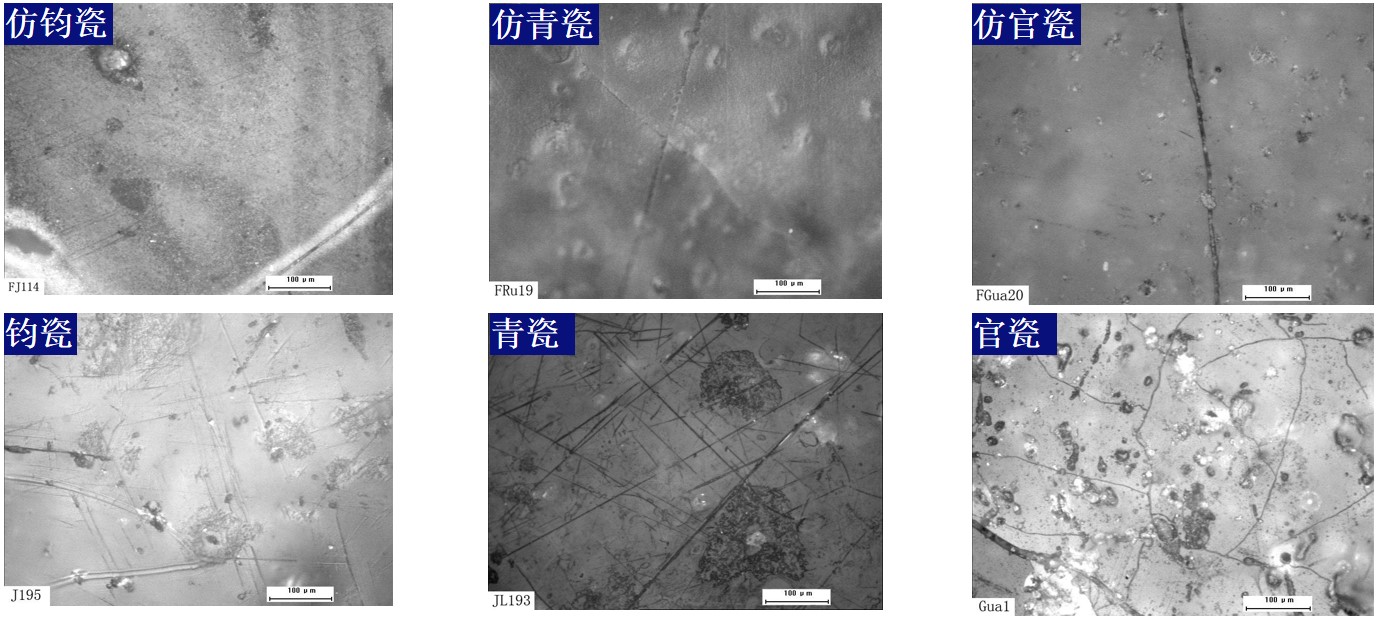

The real jade artifacts were then compared with imitations using a laser microscope (see below). Genuine and imitation jade artifacts differ in surface roughness. In contrast to traditional methods that rely on simple observation using the naked eye, the LEXT laser microscope’s noncontact roughness measurement function enabled researchers to quickly analyze the surface texture and roughness of the artifacts. The images clearly show the differences between the imitations (top row) and the real thing (bottom row).

Porcelain artifacts can also be easily analyzed using a microscope. Here, a metallurgical microscope was used to observe surface differences between ancient and modern porcelain samples. The modern imitation samples have clean surfaces, whereas the ancient samples’ surfaces show many clear, disorderly scratches. Interestingly, the surface of the imitation porcelain samples had artificially added wear that was visible as light scratches on the surface.

.jpg?rev=361E)

Conclusion

Replica artifacts can be used for nefarious purposes—such as being sold as the real thing—but they are also used by some museums when putting a real, fragile artifact on display can potentially damage it. In both cases, it’s important for archaeologists and researchers to have the tools they need to distinguish real and genuine artifacts. As demonstrated here, industrial microscopes are valuable tools to nondestructively analyze artifacts to distinguish fakes from the real thing.

Related Content

Artemis Testing Lab Identifies Authentic Artifacts Using XRF Analysis

How Archaeologists Use XRF to Source Stone Artifacts

How XRF Illuminates the Analysis of Ancient Ceramics

Get In Touch

.jpg?rev=601E)