For organizations responsible for aircraft operation and maintenance, inspection of critical aero engine components is a routine preventive maintenance procedure. These procedures are in place to ensure the proper operation of the aircraft for flight safety. There are many components inside the engine that must be inspected, including turbine blades, compressor blades, and combustion chambers.

These aero engine components are inspected visually, primarily for potential problems such as corrosion, cracks, and damage from foreign objects. As disassembling engines for inspection is time consuming and costly, industrial video borescopes are widely used for visual inspection of aero engines.

For example, when inspecting a turbine blade using a video borescope, the scope is inserted through the access port and secured in a position where the blade to be inspected is fully visible. The method of inspecting the condition of each blade by fixing the scope and rotating the turbine is generally adopted from the standpoint of inspection efficiency.

Inspections using this method take one to two hours per blade stage. During the inspection, the blades must be constantly and slowly rotated at the same speed. To perform this task, another operator is required in addition to the inspector operating the video borescope. The operator in charge of manually rotating the engine shaft using a tool and adjusting its operation in coordination with the inspector so that the blade appears on the video borescope's inspection screen at a speed that’s easy for the inspector to perform the inspection.

Visual Inspection Challenges During Manual Rotation of Turbine Blades

However, the following issues exist when manually rotating turbine blades.

First, an operator is needed just for the task of rotating the turbine, leading to inefficiencies in the inspection. Also, in noisy environments or when inspecting large engines, synchronized operation between the operator responsible for rotating the turbine and the inspector is often difficult. This can cause damage to the engine or scope due to miscommunication.

Further, the visual inspection process makes it difficult to memorize the location of potentially defective blades, which can lead to omissions. On top of that, it is difficult to manually rotate the engine shaft at a constant speed so that the inspector can easily check the condition of the blades.

An effective tool to solve these issues is a digital turning tool. In this post, we will discuss the benefits of using Enerpac’s Sweeney Digital Turning Tool (DTT) in combination with a video borescope for aircraft engine inspections.

Enerpac’s Sweeney Digital Turning Tool

Advantages of Using Digital Turning Tools

Digital turning tools are generally used to assist borescope inspection of aero engines, marine engines, and power generation turbines. They can be used to electrically turn engine turbines at any torque, speed, and angle during inspection of high-pressure compressors and high-pressure turbines. The digital turning tool is designed to improve efficiency in aeroengine borescope inspection by automating the rotor shaft positioning process.

Automation of the rotor shaft positioning process is made possible by the fact that turbine information for all engines supported by the Sweeney Digital Turning Tool is standardized in the controller. The digital turning tool has prestored blade information for each compatible engine and stage, enabling blade counting and identification. It can also memorize the position of a potentially defective blade, making it easy to go back and recheck that position.

The digital turning tool eliminates the need for an operator to rotate the engine shaft and provides higher efficiency than manual operation. It also provides stable operation and maintenance of rotational speed, automatic blade counting, and flagging (i.e., the ability to automatically return to a given turbine blade that has been flagged during the inspection).

Solving Challenges in Borescope Inspection of Major Aircraft Engines

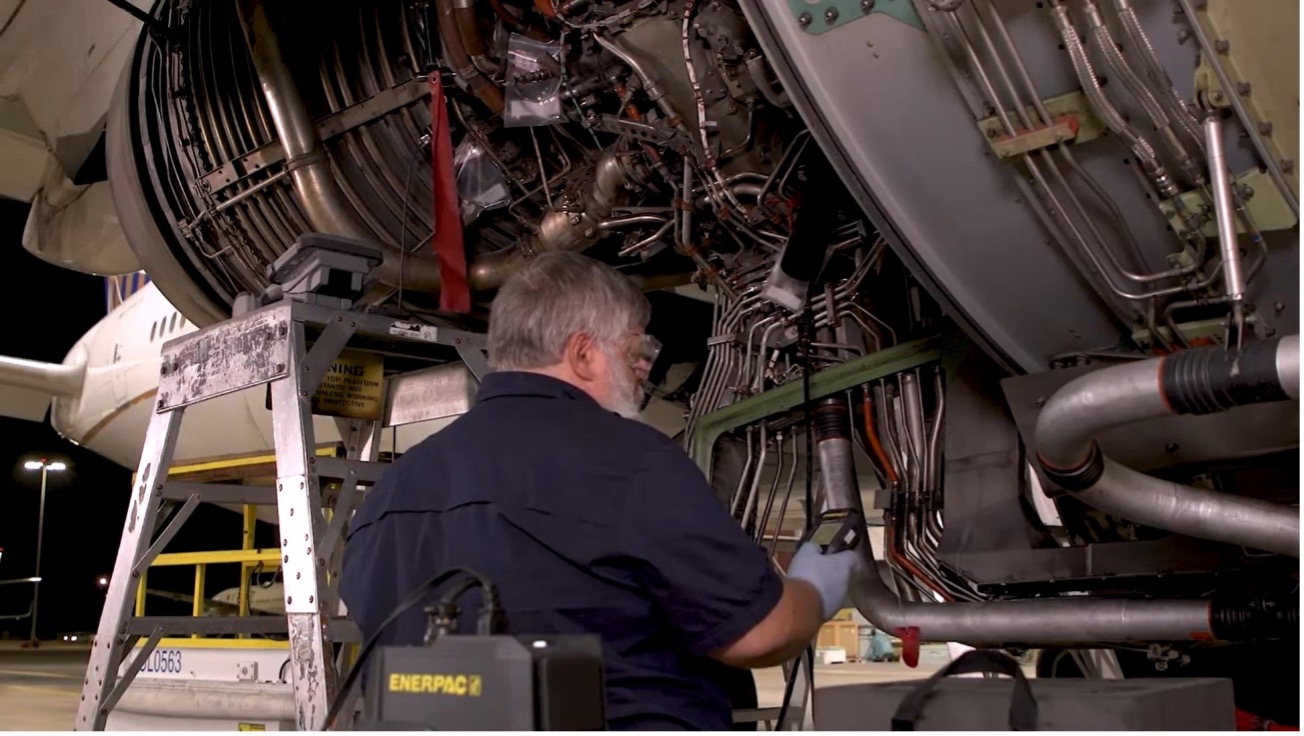

Let’s explore how the digital turning tool aids in the borescope inspection of some major aircraft engines. For example, in a GEnx engine, it is difficult to connect a ratchet wrench to the engine for manual rotation as the access port used to rotate the turbine is surrounded by pipes and wire harnesses. Also, the range of motion of the ratchet wrench is narrow, and the angle at which it can be rotated at one time is limited to 15 degrees.

GEnx engine. Image courtesy of Georges Seguin (Okki), CC BY-SA 3.0, via Wikimedia Commons.

This structural constraint was forcing engine inspectors and operators to work long hours. These challenges in the engine inspection can be solved by using the Sweeney Digital Turning Tool.

Attach the Sweeney Digital Turning Tool to the engine access port, and its drive motor enables you to turn the turbine blades.

This digital turning tool has adapters and shafts specifically designed for GEnx engines to provide stable drive motor connections even in tight access port areas. After installing these adapters and shafts, the engine can be inspected safely and efficiently by connecting the drive motor to the adapter.

Another pain point is the force required for manual rotation. For example, the GEnx engine is classified as a medium-to-large engine with 55,000 to 75,000 pounds of thrust. Manually rotating the engine using a ratchet wrench requires a considerable amount of force and stability in the rotational operation.

The digital turning tool's drive motor output, adjustable from 30 to 150 ft lb, eliminates this pain point because the high torque lets the engine rotate at a steady speed. This is accomplished by a compact, powerful electric motor in the drive motor. As a result, engine inspections can be performed more efficiently than with manual rotation.

In addition, the digital turning tool has features to prevent damage that may occur accidentally during rotation. During operation, a built-in torque overload sensor stops operation if excessive torque is generated. It can also detect if a scope is caught in a turbine component. This greatly reduces the risk of damage to expensive scopes and turbine components and enables safe engine inspections.

Tips for Inspecting Aircraft Engines That Contain a Gearbox

Some aero engines have a gearbox in their construction, such as the PW1100G series and the V2500 engine. To turn the engine, the high-pressure system must be rotated through the gearbox, and inspectors and operators must expend a great deal of effort to do so. Normally, a hexagonal socket or ratchet wrench is used to rotate the rotor. A large amount of force is required to rotate the high-pressure rotor due to the gearbox. If the force is not adjusted properly, the high-pressure rotor will rotate too quickly.

Once again, a digital turning tool can be used to rotate the rotor stably at high torque.

Learn More about Digital Turning Tools in Aircraft Engine Inspection

To increase inspection efficiency and probability of defect detection in aero engines, we recommend combining Enerpac’s Sweeney Digital Turning Tool with an IPLEX™ series video borescope. Learn more about these advantages in the following video.