The adoption of electric vehicles, also called EVs or battery-electric vehicles, continues to grow rapidly. While electric cars are popular for their lower emissions, higher fuel savings, and lower maintenance costs, battery safety remains a concern.

Lithium-ion batteries, which are used to power EVs and many portable electronics, can overheat if they are improperly manufactured or damaged. This can cause the battery to catch fire—or even explode. To prevent these risks, various standards and inspection processes for lithium battery safety are in place around the world.

One useful inspection tool used for lithium-battery safety is the industrial microscope. This post discusses how different types of industrial microscopes support the inspection of lithium-ion batteries for EVs.

How Does a Lithium-Ion Battery Work?

Put simply, a lithium-ion battery is a rechargeable battery that generates electricity through the movement of lithium ions. The four main components in a lithium-ion battery are a cathode, anode, electrolyte, and separator.

- The cathode is a positive electrode (typically a metal oxide) and is the source of lithium ions. It determines the battery’s capacity and voltage.

- The anode is a negative electrode (typically graphite) that generates electricity by storing and releasing the lithium that came from the cathode.

- The electrolyte acts as a conductor that facilitates the movement of lithium ions between the anode and cathode.

- The separator (e.g., diaphragm) is a thin membrane that prevents physical contact between the anode and cathode. This barrier prevents the direct flow of electrons (important to prevent a short circuit) while allowing the passage of lithium ions through tiny holes.

When a lithium battery discharges, lithium ions move from the anode to the cathode. This discharging process provides the electrical energy needed to operate various devices. When plugging in the device, the charge reverses this movement—the lithium ions move from the cathode to the anode.

The entire power battery system depends on battery safety to perform well. A battery cell that short circuits can cause a fire, explosion, or other accidents. Contamination or damage introduced during the manufacturing process can also affect battery safety and performance. For this reason, it is critical to have rigorous inspection processes throughout battery production.

Inspection Processes to Support Lithium-Ion Battery Safety and Performance

Inspectors must check various components during the manufacturing of lithium-ion batteries to confirm the parts are clean and free of defects. This includes:

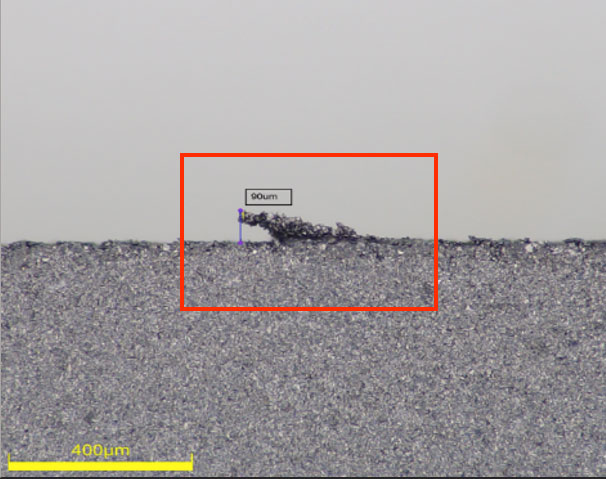

1. Inspecting electrode plate burrs

First, it is important to monitor electrode burrs in the manufacturing process. If electrode burrs are too long, they will pierce the diaphragm and cause a short circuit. To prevent these risks, electrode burrs need to be carefully monitored and measured. Further, the diaphragm quality can greatly affect the battery performance. Inspectors must check the diaphragm to detect surface scratches and other defects.

Industrial microscopes can help with these inspections. Using our DSX1000 digital microscope, you can:

- Observe burrs from multiple angles to clearly see their condition and avoid overlooking any defects

- Measure the size of the burrs

- Use the differential interference contrast (DIC) observation method to check for scratches and other defects on the diaphragm

Observation of an electrode plate burr using the DSX1000 digital microscope

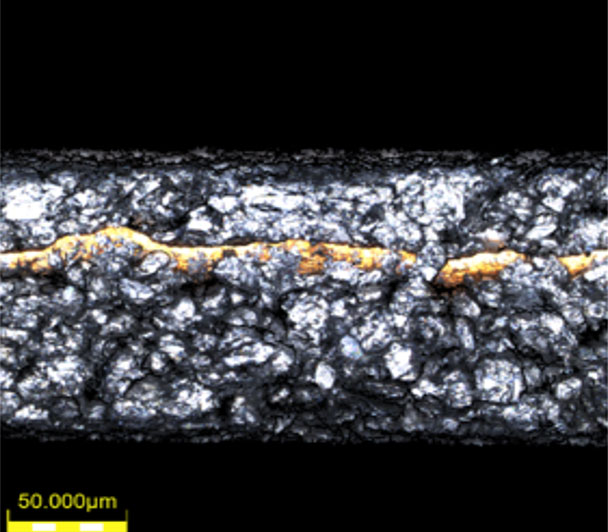

2. Inspecting the battery casing and electrode plates

After the coating and slitting of electrodes, the electrode layer thickness must be measured microscopically.

The DSX1000 microscope offers 3D scanning and measuring to take precise measurements. With these capabilities, you can measure the thickness of an electrode plate’s cross-section, the thickness of each of its layers, and its surface angle.

3D measurement of an electrode plate cross-section

The battery casing and electrode plates must also be tested for technical cleanliness to prevent metal contamination from entering the parts. Metallic fibers can cause a short circuit in the battery if the intermediate layers are punctured.

Using our automated OLYMPUS CIX100 system, you can inspect the cleanliness of lithium battery casing and electrode plates in real time. The system quickly captures an image of contamination while classifying and measuring the size of individual contaminant particles. As the system detects reflective (metallic) and non-reflective particles in one scan, you can swiftly determine if any metallic fibers are present.

After inspection, the system generates compliant reports at the click of a button. Results are accurate and reproducible thanks to the pre-calibrated system, mechanical stability, and automated control.

OLYMPUS CIX100 technical cleanliness inspection system

Example cleanliness inspection of fibers using the OLYMPUS CIX100 system

Microscopes and Other Tools for Lithium-Ion Battery Safety

The applications above demonstrate the important role digital microscopes and technical cleanliness inspection systems play in lithium-ion battery manufacturing. Other industrial tools, such as laser scanning microscopes and handheld XRF analyzers, can also assist with inspection and quality control during lithium-ion battery production.

To learn more, check out our resource center on solutions for lithium-ion battery manufacturing.

Related Content

Microscope Solutions for Lithium-Ion Battery Manufacturing

Measuring the Roughness of Lithium-Ion Battery Electrodes

The Role of Handheld XRF in the High-Power Lithium-Ion Battery Supply Chain

Get In Touch

.jpg?rev=A905)