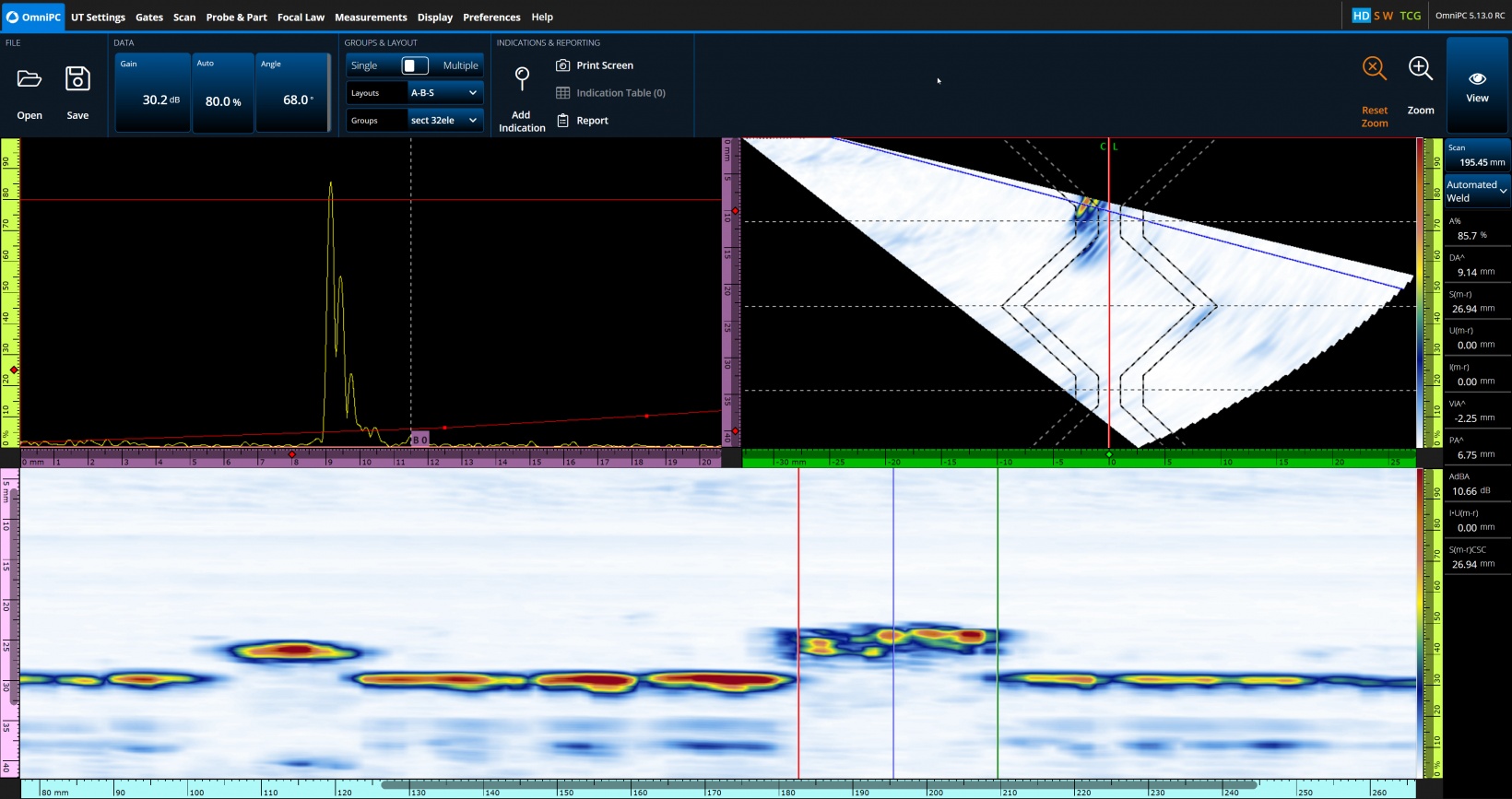

There are several advantages to acquiring encoded phased array (PA) ultrasonic data using advanced flaw detectors such as our OmniScan™ X3 series. It enables you to size defects using data views that represent their dimensions accurately. These dimensions can be used to perform fit-for-service calculations, enabling asset owners to confidently make critical decisions concerning operational safety and the necessity for intervention.

The equipment required to acquire encoded PA data is increasingly portable and affordable. The right flaw detector, scanner, probe, and encoder combination can provide you the capabilities to address different applications and acquire more valuable data. However, despite all the advances that have been made in scanning technology, many scanners have drawbacks in terms of portability.

Challenges of Automated and Semiautomated Scanners

Although automated and semiautomated scanners typically enable higher throughput and the ability to address more complex applications, they may not be appropriate for the job at hand. Here are 3 reasons why a simpler equipment setup may be preferable:

- Size−If the targeted area or weld to inspect is in a position with limited space, the scanner may not fit.

- Configuration−The design or shape of the scanner may be an inhibiting factor to installing it on the component.

- Complex or cumbersome−When scanners are heavy, bulky, or difficult to install, this can act as a deterrent to using them.

Without a scanner, an inspector may opt to scan manually and forego encoding the data. Ensuring you have the right equipment can help avoid returning from a job with unencoded data.

Acquire Encoded Data Every Time

Once on the job site, you and your crew have no choice but to make do with the equipment on hand. Being truly prepared means having versatile scanning tools that accommodate a range of component sizes, types, and materials and adapt to different environments.

To achieve that level of readiness and adaptability, consider adding these 3 scanning and encoding tools to your PA inspection toolkit:

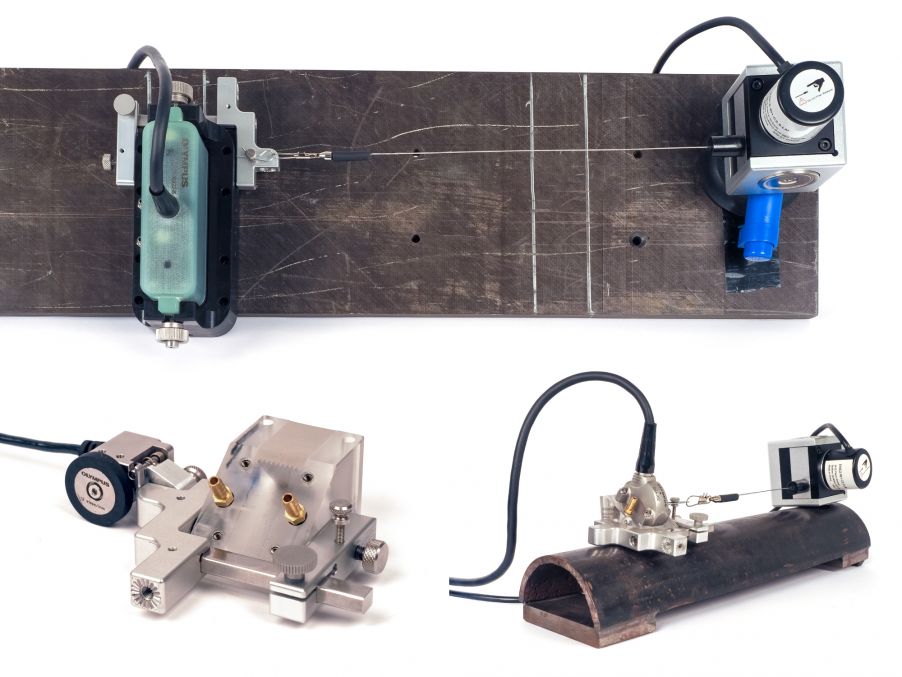

1. Wire Encoder

When you’re in tight spot, the streamlined one-wire design of the wire encoder can help you out of a bind. Its simple pull motion requires minimal effort, enabling you to easily perform one-axis encoded phased array scanning.

Here are features that make it so versatile and easy to operate:

- 2 mounting bases (magnetic and suction cup) easily install on all surfaces, both ferromagnetic and nonferromagnetic.

- Fits in areas with limited space because of its small footprint

- When packed for transport, it’s highly portable and requires minimal space, so you can always bring it along as a backup.

- Mistakes are minimized due to its positioning system, removing the risk for slippage errors, and its easy pull operation lets the operator focusing on properly manipulating the probe.

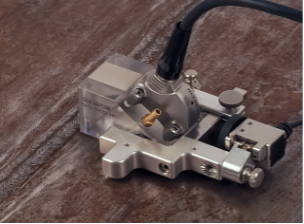

2. Universal Holder

Without any tools required, our universal holder attaches to the wire encoder or Mini-Wheel™encoder in up to three different orientations, accommodating almost any phased array (PA) wedge and probe combination. It’s an easy and economical way to improve your ability to adapt your setup at a moment’s notice.

Adding the universal holder to your inspection equipment enables you to create configurations for a wider range of part shapes and sizes. You can also expand the types of probes and wedges that you can use for encoded inspection, increasing your versatility. In situations where using a wedge is impossible, it can be attached directly to a phased array probe to perform contact inspection.

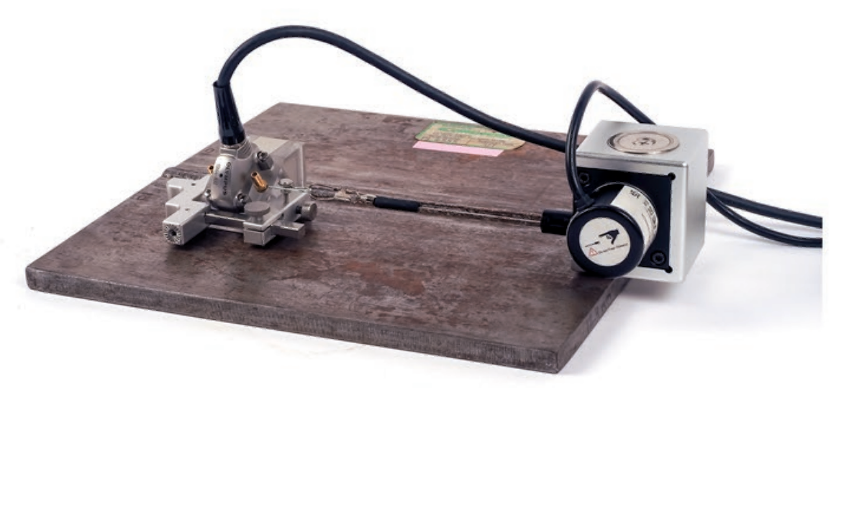

3. Mini-Wheel™ Encoder

The Mini-Wheel™ encoder is a tried and tested scanning tool, already appreciated for its versatility. As well as being rugged and compact, it has a rubber wheel for nonferromagnetic surfaces at temperatures up to 150 °C (302 °F) or a magnetic wheel for maximum adherence on ferromagnetic parts.

The Mini-Wheel encoder can be used in several different configurations to meet the requirements of specific inspection applications, for example:

|   |

Be Prepared to Overcome Obstacles to Encoded Data

To sum up, here are the key shared advantages of these three tools:

- Compactness

- Versatility

- Simplicity

Since they are easy to transport and operate, you can add them to your standard inspection equipment without increasing the stress or burden for you or your crew. They may seem like a relatively minor investment, but they are worth their weight in gold when you consider the peace of mind that you’ll gain.

Don’t wait until the next time you’re in the field and faced with a difficult inspection hurdle! Talk to your local Evident sales rep today to discuss these as well as our other scanning and encoding solutions.

Related Content

Brochure: Industrial Scanners Catalog

Ahead of the Curve: UT is Finally Flexible Enough for Pipe Elbow Inspection

Get In Touch