Within every busy operational maintenance squadron, propulsion shop, and intermediate maintenance facility, military inspection equipment is put through its paces. Even when the best equipment care practices are followed, military aircraft maintainers need tools that are built to endure rough conditions and constant transport.

|  |

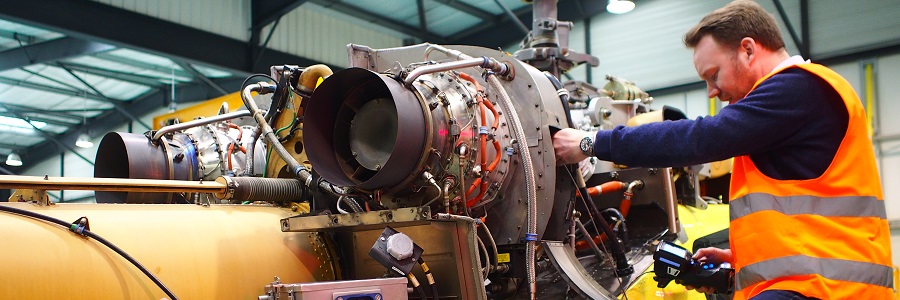

Regular preventative remote visual inspections are part of maintaining the mission readiness of military aircraft |

Aircraft Maintainers Need Robust Remote Visual Inspection Tools

Military maintenance crews need reliable and durable remote visual inspection (RVI) tools, such as borescopes and videoscopes, to help ensure effective support of global flight operations. Maintenance crews must regularly check the complete structure of each aircraft—inside and out—to inspect for any potential or existing damage. If the damage is severe enough, a decision must be made to keep the aircraft in service or pull it out for further review.

5 Ways IPLEX Videoscopes Are Fit for Military Applications

Using our IPLEX™ series videoscopes, aircraft maintainers can perform critical inspections of fixed-wing and rotary-wing platforms, from the engine to tail rotor. Here are 5 important videoscope features that facilitate the job of aircraft maintenance crews:

1. Portability

For aircraft maintainers that need a lightweight option, the IPLEX G Lite videoscope offers handheld portability in a compact frame. Its small size is an advantage for troops who are often on the move, work in close quarters such as in naval aviation, or undergo rapid deployments around the world.

2. Image Quality

For maintainers in engine shop environments, our IPLEX GX/GT videoscopes come with larger screen monitors and brighter images to give a clear view inside dark, cramped spaces, enabling operators to perform critical inspection measurements.

3. Ease of Use

The IPLEX GX/GT videoscope’s large screen also makes it easy to provide training, share findings, or certify other operators if you are a borescope certifier.

All IPLEX series models offer a user-friendly interactive navigation menu, so maintainers can get quick results easily. The simple controls also ease making adjustments and taking measurements while they’re navigating the insertion tube inside an asset.

4. Durability

In maintenance work centers, such as phase hangers or isochronal (ISO) docks, the pace of the work can make durability important.

Every IPLEX videoscope is built and tested to meet U.S. military standards and certified to MIL-STD 810 and EMI-STD 461. The IPLEX series videoscopes are reliable units that can withstand the demanding and sometimes harsh working conditions of military aircraft maintenance.

5. Easy FOD Retrieval

Part of an aircraft maintainer’s job is to inspect for cracks, dings, dents, and any other foreign-object-debris (FOD) indications in the compressor and fan components. The working channel tools on our IPLEX NX videoscope insertion tubes enable quick FOD retrieval.

Equipping military maintenance crews with practical tools such as these help them perform efficient and exhaustive videoscope inspections. Thorough visual inspections of difficult-to-access and critical parts of aircraft increase flight operators’ confidence in their vehicle’s safety and reliably.

Proud Military Supplier for 5 Decades

Over the last 50 years, Olympus has been a proud equipment supplier of the US military. Today, many branches of the military and allied forces utilize Olympus products for their inspection needs. Our products are used to help ensure the integrity of many aircraft, fighters, bombers, refueling tankers, and cargo lifters, including the Joint Strike Fighter (JSF) program.

In the United States, Olympus IPLEX videoscopes and accessories are also available on the GSA schedule. Access these GSA items through www.gsaadvantage.com or your local Olympus representative.

To learn more about Olympus or the IPLEX series, visit www.olympus-ims.com/videoscope.

Related Content

3 Reasons to Add a Working Channel Scope to Your RVI Toolbox

Collaboration Helps Military Veterans Transition into NDT Careers

Get In Touch