With the release of WeldSight™ advanced analysis software for OmniScan™ X3 acquisition data (.odat files), you may be asking yourself what does WeldSight have that OmniPC™ software doesn’t. First, let’s look at the similarities and then we’ll compare the differences.*

WeldSight software comes equipped with OmniPC software users’ favorite tools:

- Standard post-process corrections (gain, Auto 80%, index and scan offsets, and gate editing)

- Basic reporting and indication table

- Basic analysis tools (linked cursors, TOFD calibration, multiple window capability, and keyboard mouse shortcuts)

- Views displaying the left and right sides of a weld

- Side-by-side on-screen comparison of current and previously captured inspection files

These practical tools may suffice for basic phased array ultrasonic testing (PAUT) data analysis. Where WeldSight software differs from OmniPC, however, is its advanced features that can assist weld inspectors with more complex applications, pushing their data analysis even further.

Advanced PA Analysis Tools for Weld Testing Applications

WeldSight software is optimized to provide OmniScan X3 users with advanced analysis for both in-service and new construction weld applications. It contains the tools and features for compliance to ISO, API, ASME, and similar fabrication codes.

Here are some of the noteworthy features that are exclusive to WeldSight software:

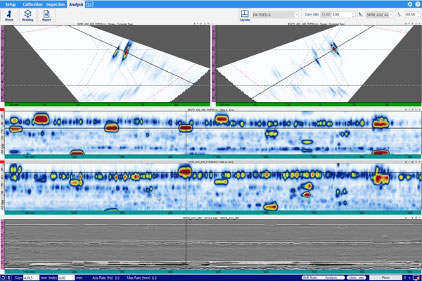

Gain a comprehensive understanding of the entire part with data and file merging

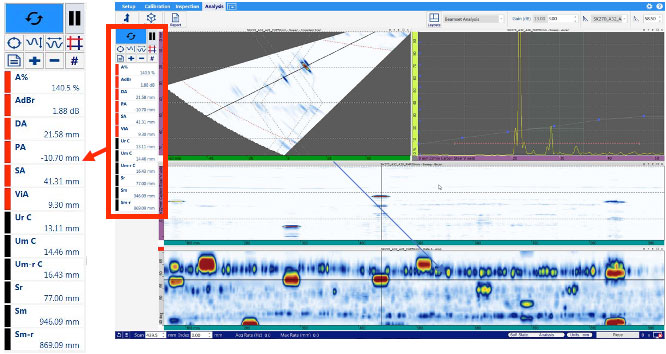

Volumetric data merge: Screen the whole weld of large parts in one view to efficiently evaluate indications. After merging the data, the software produces Top/Side/End views with projection and slice cursors. Projection cursors offer a full view of the sample while filtering unwanted echoes.

File merge: Independently acquired data files are stitched together, so all indications appear together in one image.

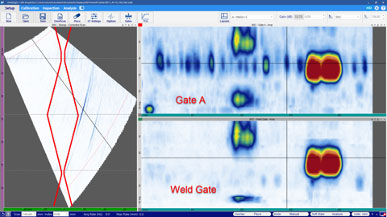

Isolate and focus on data acquired inside the weld

The weld gate is an exclusively post-acquisition geometry-based gate, which uses data from inside the weld to generate a C-scan. With a click, you can automatically position the cursors at the maximum amplitude position. WeldSight software also offers easy shortcuts that enable you to zoom in on specific sections of the scanned data.

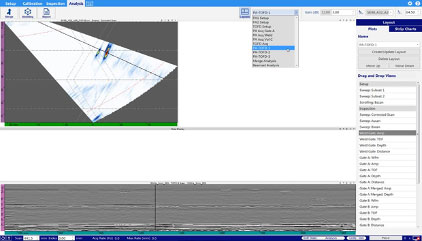

Arrange the data to your preference or procedure using the drag-and-drop custom layout

Drag and drop the desired data display from Layout manager.

Save your layout so it’s always arranged in a specific way or to suit a particular procedure.

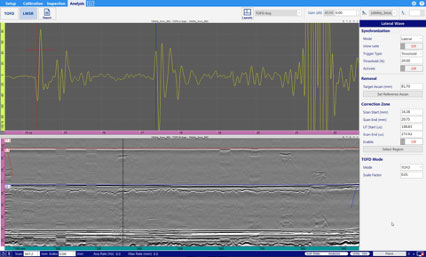

Facilitate sizing and analysis with advanced TOFD support

WeldSight software’s enhanced time-of-flight diffraction (TOFD) tools include TOFD calibration, lateral wave straightening and synchronization, synthetic aperture focusing technique (SAFT), linearized mode, and TOFD gate for lateral wave monitoring.

Audit UT settings and missed data points

The analysis dashboard uses the familiar OmniScan nomenclature for the trigonometry gate readings, cursor readings, and sizing statistics. The missing data statistics let you know at a glance how much data was missed during the inspection.

Enhance your reporting with 3D and polar representations

Make the location and severity of flaws clearer for clients who are inexperienced at interpreting PAUT data.

More information about WeldSight software’s features as well as a chart comparing its features with those of OmniPC software can be found here. If you have questions about which software is right for your application, don’t hesitate to contact Olympus to discuss your specific analysis needs.

*This is a comparison of these software versions: WeldSight 1.2R5 and OmniPC 5.4. The features of each software will change and evolve with subsequent versions.

Related Content

Video: WeldSight™ Software for the OmniScan™ X3 Flaw Detector

.jpg?rev=B773)