The chemical composition of stainless steel significantly influences its properties, impacting its performance, cost, and lifespan. Understanding key factors and checking proper chemical composition can guide you toward the best option for your specific application.

Here are seven critical considerations, each with practical examples and grade recommendations to help you make an informed decision when selecting stainless steel for your needs:

1. What Resistance Does the Steel Need to Provide?

Stainless steel's resistance to environmental factors is one of its hallmark traits. Corrosion resistance is essential for applications exposed to acids, chlorides, or harsh industrial and marine conditions. Similarly, temperature resistance—both high and low—should be factored in for extreme environments.

- Corrosion Resistance: For marine environments, grades 316, 316L, and 904L are ideal due to their resistance to pitting and chloride corrosion. In industrial settings, 2205 duplex stainless steel offers enhanced corrosion resistance and strength.

- High-Temperature Applications: Heat-resistant grades such as 310, S30815, and 446 are commonly used for furnace parts and heat exchangers.

- Cryogenic Environments: Low-temperature grades including 304LN, 316, and 904L retain toughness and strength in extreme cold, making them ideal for LNG storage tanks or cryogenic piping.

2. How Important is Formability?

Formability determines how easily the material can be shaped without cracking or losing its structural integrity.

3. Does Your Steel Require Machining?

Stainless steel’s machinability varies by grade and composition. Work hardening during machining can pose challenges, but certain grades, such as 303 or 416, include sulphur to enhance machinability.

- Easy-to-Machine Grades: 303 and 416 are ideal for producing machined components such as screws, fasteners, and gears. These grades balance machinability and acceptable corrosion resistance.

- Balanced Machinability and Resistance: 3CR12 works well for conveyor belts and mining components where wear resistance and machinability are equally important.

4. Will Welding Be Necessary?

Welding introduces risks such as cracking and corrosion in stainless steel if the wrong grade is used.

- Ideal for Welding: 304L and 316L are widely used for food-grade equipment, such as tanks and piping, due to their low carbon content, which minimizes intergranular corrosion at weld joints.

- Specialized Welding: For chemical processing plants, 347 (stabilized with niobium) offers excellent resistance to stress corrosion cracking and high weldability.

5. Does the Application Require Heat Treatment?

Heat treatment alters the mechanical properties of stainless steel, making it a crucial consideration for certain applications.

- Hardenable Grades: 440C and 17-4PH are commonly used in precision tools, such as surgical instruments and cutting blades, as they achieve high hardness and wear resistance after heat treatment.

- Non-Hardenable Grades: If you’re producing decorative panels or cladding, austenitic grades such as 304 and 316 are preferred as they maintain strength and surface finish without requiring hardening.

Automotive gear components require a stainless steel with properties that offer a balance of corrosion resistance and machinability.

6. What Strength Does the Steel Need to Provide?

Choosing the correct strength ensures safety without unnecessary costs or weight.

- High-Strength Grades: Martensitic steels such as 440C and precipitation-hardening steels such as 17-4PH provide the superior strength and durability required for aerospace and automotive components.

- Moderate Strength and Ductility: 316 and 304 are commonly used for structural applications such as handrails or bridges, where a balance of strength and flexibility is required.

- Dual Strength and Corrosion Resistance: Duplex grades such as 2205 and 2507 are used in offshore platforms and chemical storage tanks for their excellent strength and resistance to stress corrosion cracking.

Different alloys exhibit distinct physical characteristics, such as hardness, corrosion resistance, and strength, which are influenced by factors like their chemical composition, microstructure, heat treatment, and the presence of alloying elements.

In a table below you can see the variations in these characteristics.

| Grade | Hardness (scale) | UTS (MPa) | PREN |

| 304 | 70 HRB | 505 MPa | 18-20 |

| 316 | 80 HRB | 550 MPa | 23-29 |

| 310 | 85 HRB | 620 MPa | 18-20 |

| 904L | 79 HRB (≈180 HB) | 600 MPa | ≈34 |

| 2205 | ≤ 31 HRC (≤ 293 HB) | ≤ 31 HRC (≤ 293 HB) | 28–38 |

| 3CR12 | 88 HRB (180 HB) | ≥ 455 MPa | 11–13 |

| 17-4PH | 44 HRC | 1300 MPa | 15–17.5 |

| 303 | 70 HRB | 620 MPa | 18-20 |

| 416 | 82 HRB | 515 MPa | n/a |

| 347 | 94 HRB | 690 MPa | 18–20 |

| 430 | 85 HRB | 483 Mpa | n/a |

7. How Do Upfront and Lifetime Costs Compare?

The cost-effectiveness of stainless steel depends on its suitability for your environment and application.

- High-Corrosion Resistance with Longevity: For water treatment or desalination plants, 316 or 2205 may have higher upfront costs but reduce maintenance and replacement over time.

- Cost-Effective Options: In indoor applications, such as elevator panels or decorative railings, 430 or 3CR12 provide lower initial costs while meeting performance requirements.

GradeChromium (Cr)Nickel (Ni)Carbon (C)Molybdenum (Mo)Manganese (Mn)Silicon (Si)Nitrogen (N)Other elements

| Effect on stainless steel | Improve oxidation resistance and hardenability | Improve strength, hardness, ductility | Improve strength, hardness | Improve hardness, high temperature strength, corrosion resistance | Improve strength and minimize deoxidation | Improve strength, hardness oxidation resistance | Improve corrosion, pitting, crevice resistance | |

|---|---|---|---|---|---|---|---|---|

| 304 | 18.0–20.0% | 8.0–10.5% | ≤0.08% | – | ≤2.0% | ≤0.75% | – | – |

| 316 | 16.0–18.0% | 10.0–14.0% | ≤0.08% | 2.0–3.0% | ≤2.0% | ≤0.75% | – | – |

| 310 | 24.0–26.0% | 19.0–22.0% | ≤0.25% | – | ≤2.0% | ≤1.50% | – | – |

| 904L | 19.0–23.0% | 23.0–28.0% | ≤0.02% | 4.0–5.0% | ≤2.0% | ≤1.00% | – | Copper (1.0–2.0%) |

| 2205 | 21.0–23.0% | 4.5–6.5% | ≤0.03% | 2.5–3.5% | ≤2.0% | ≤1.00% | 0.08–0.20% | – |

| 3CR12 | 10.5–12.5% | ≤1.5% | ≤0.03% | ≤0.6% | ≤1.5% | ≤1.00% | – | Phosphorus (≤0.04%), Sulphur (≤0.015%) |

| 17-4PH | 15.0–17.5% | 3.0–5.0% | ≤0.07% | ≤0.50% | ≤1.0% | ≤0.50% | – | Copper (3.0–5.0%), Niobium (≤0.45%) |

| 303 | 17.0–19.0% | 8.0–10.0% | ≤0.15% | – | ≤2.0% | ≤1.00% | – | Sulphur (0.15–0.35%) |

| 416 | 12.0–14.0% | ≤1.5% | ≤0.15% | – | ≤1.25% | ≤1.00% | – | Sulphur (0.15–0.35%) |

| 416 | 12.0–14.0% | ≤1.5% | ≤0.15% | – | ≤1.25% | ≤1.00% | – | Sulphur (0.15–0.35%) |

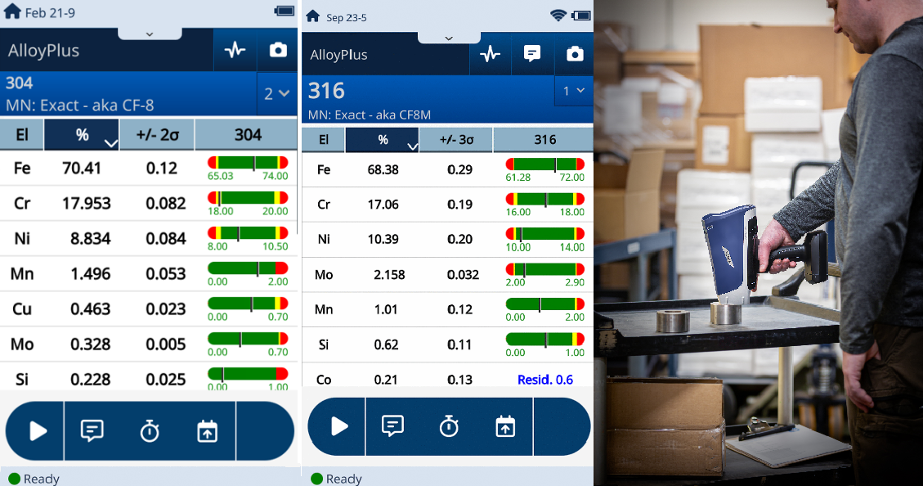

Simplify Your Choice with Accurate Grade Identification

Choosing the right stainless steel grade for your needs can be complex, but ensuring its accuracy is even more critical. Maintaining full control over the materials you purchase reinforces product reliability and performance, prevents costly errors, and enables compliance with quality standards.

Vanta handheld XRF analyzers provide instant grade match messages in real-time with familiar trade or grade names, reducing the training curve and increasing efficiency.

The Vanta® portable X-ray fluorescence (pXRF) analyzer can be an invaluable tool in achieving this, providing precise, nondestructive grade identification and composition analysis. By integrating pXRF technology into your workflow, you can streamline your material selection process and enhance your confidence in every purchase.

Related Content

9 Quick Tips for End-to-End Manufacturing Quality Control

VDM Metals Exceeds Client Expectations with Vanta™ Handheld XRF

How Does XRF Work? Understanding X-Ray Fluorescence

3 Important Considerations when Using X-ray Fluorescence for Positive Material Identification