Microscope Solutions for

PCB Manufacturing

- Home

- Microscope Solutions for PCB Manufacturing

- Making the Substrate

Making the Substrate

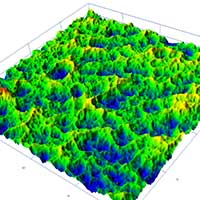

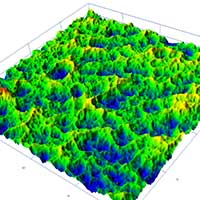

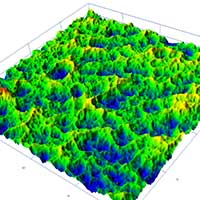

Make a substrate using glass and epoxy, then cover it with copper foil. The surface roughness of the copper foil must be carefully inspected because it influences the quality of the PCB.

Analyzing the Surface of Copper Substrate

Minute defects on the surface will impact the quality of the substrate. Inspectors must detect and measure the size of minute defects (micro-level) on the copper substrate surface.

Our Solution

Our DSX1000 digital microscope can provide 3D images, enabling you to easily analyze the surface condition of the substrate. The microscope can also measure the width and depth of minute defects.

DSX series digital microscope |  Surface analysis of substrate |

Application Notes

Explore related applications:

|

| ||

|

|

Analyzing the Surface of Copper Substrate

A rough copper substrate surface will affect the lamination quality, so measuring the surface roughness on the copper substrate is critical for ensuring the quality of PCBs. A contact-type roughness measurement instrument cannot be used because it will create defects on the copper substrate.

Our Solution

Our OLS series laser scanning microscope can provide a noncontact roughness measurement for a copper substrate surface. It measures without damaging the surface and can capture data of a rough surface more accurately than with a white interferometer due to high lateral resolution.

OLS series laser scanning microscope |  Surface analysis of substrate |

Application Notes

Explore related applications:

|

| ||

|

| ||

|

|