Support

DSX1000 Digital Microscopes - Entry Model

Loading...

Overview

Easy to Use with Basic Functionality

DSX1000 Entry Model

Preliminary Inspection and Micron-Level Analysis with One System

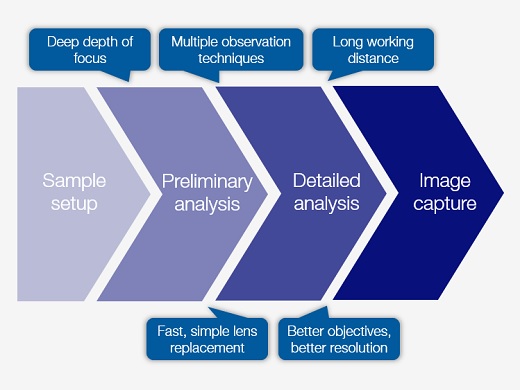

Reduce trial and error during observations for faster inspections

Conduct an initial macro analysis and detailed micro analysis using one instrument

Choose the Best Lens for Your Analysis

Our lineup of 17 objective lenses provides flexibility to obtain a wide range of images

Minimize the chance of crashing into your sample with a long working distance

High resolution and a long working distance in one objective

See all the objectives

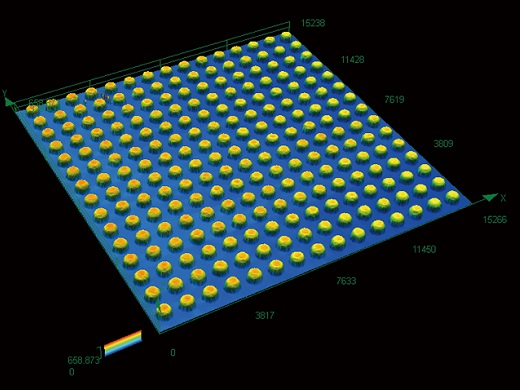

Be Confident in Your Measurements

Telecentric optical system enables you to obtain high-precision measurement with guaranteed accuracy and precision*

*To guarantee XY accuracy, calibration work must be undertaken by an Evident service technician.

5 Advantages of the DSX1000 Series Digital Microscope Over Conventional Digital Microscopes

01 All-in-One System with a Wide Magnification Range

With the DSX1000 digital microscope:

Complete your inspection using one easy-to-use system

With a conventional digital microscope:

Two microscopes, a low-magnification and a high-magnification model, are needed to complete an inspection

02 High-Resolution Image at High Magnification

With the DSX1000 digital microscope:

High resolution and long working distance in one objective

With a conventional digital microscope:

Resolution decreases as magnification increases

03 Long Working Distance Objectives

With the DSX1000 digital microscope:

Observe uneven samples without bumping into them

With a conventional digital microscope:

The objective can crash into the sample, potentially damaging it

04 Multiple Observations with a Single Click

With the DSX1000 digital microscope:

All 6 observation methods are available at all magnifications

With a conventional digital microscope:

Only one or two observation methods are available, limiting what can be seen in the sample

05 Guaranteed Accuracy and Precision

With the DSX1000 digital microscope:

Both accuracy and repeatability are guaranteed at all magnifications

With a conventional digital microscope:

The measurement precision is not guaranteed

Get more details about the advantages

Models

DSX1000 Digital Microscope Lineup

You can meet various observation needs with the DSX1000 Series from entry level to high end.

See Full Specifications Chart

DSX1000 Objective Lenses

Our lineup of 17 objective lenses, including super long working distance and high numerical aperture options, offers flexibility to obtain a wide range of images.

Super Long Working Distance Objective Lens Provides a long working distance between the lens and sample.

View Product Details

High-Resolution, Long Working Distance Objective Lens Delivers both high resolution and a long working distance.

View Product Details

High-Performance, High Numerical Aperture Objective Lens Delivers high performance at the nano scale.

View Product Details

Specifications

DSX1000 Digital Microscope Specifications

DSX10-SZH

DSX10-UZH

Optical System

Optical system

Telecentric optical system

Zoom ratio

10X (motorized)

Zoom magnification method

Motorized

Calibration

Automatic

Lens attachment

Quick-switch, coded lens attachments automatically update magnification and visual field information

Maximum total magnification

9637X

Working distance (W.D.)

66.1 mm – 0.35 mm

Accuracy and repeatability (X-Y plane)

Accuracy*1

± 3%

Repeatability 3σn-1

2%

Repeatability (Z axis)*2

Repeatabilty σn-1

1 μm

Camera

Image sensor

1 / 1.2 inch, 2.35 million pixel color CMOS

Cooling

Peltier cooling

Frame rate

60 fps (maximum)

Low

960 × 600 (16:10)

Medium

1600 × 1200 (4:3) / 1920 × 1080 (16:9) / 1920 × 1200 (16:10) / 1200 × 1200 (1:1)

High (pixel shift mode)

2880 × 1800 (16:10)

Super high (pixel shift mode)

5760 × 3600 (16:10)

3CMOS mode (high quality)

Not available

Available (high and super high modes only)

Illumination

Color light source

LED

Lifetime

60,000 h (design value)

Observation

BF (brightfield)

Standard

OBQ (oblique)

Standard

DF (darkfield)

Standard

MIX (brightfield+darkfield)

Standard

PO (polarization)

Standard

DIC (differential interference)

Not available

Standard

Contrast up

Standard

Depth of focus up function

Not available

Standard

Transmitted lighting

Standard*3

Focus

Focusing

Motorized

Stroke

101 mm (motorized)

*1 Calibration by an Evident or a dealer service technician is necessary. To guarantee the accuracy of XY, calibration with DSX-CALS-HR (calibration sample) is required. To issue certificates, calibration work must be undertaken by an Evident calibration service technician. *2 When using a 20X or higher objective. *3 The optional DSX10-ILT is required.

Objective

DSX10-SXLOB

DSX10-XLOB

UIS2

Objective lens

Maximum sample height

50 mm

115 mm

145 mm

Maximum sample height

50 mm

Parfocal distance

140 mm

75 mm

45 mm

Lens attachment

Integrated with lens

Available

Total magnification

27 – 1927X

58 – 7710X

34*4 – 9637X

Actual F.O.V. (μm)

19,200 µm – 270 µm

9,100 µm – 70 µm

17,100 µm – 50 µm

Adaptor

Diffusion adaptor (optional)

Available

Not Available

Eliminate reflection adaptor (optional)

Available

Not Available

Lens attachment

Number of objectives that can be attached

Up to 1 piece

Up to 2 pieces

Objective lens case

Three lens attachments can be stored

*4 Total (maximum) magnification when using MPLFLN1.25X

Stage

DSX10-RMTS

DSX10-MTS

U-SIC4R2

XY stage: motorized / manual

Motorized (with rotation function)

Motorized

Manual

XY stroke

Stroke priority mode: 100 mm × 100 mm

100 mm × 100 mm

100 mm × 105 mm

Rotation angle

Stroke priority mode : ±20°

Not available

Display rotation angle

GUI

Not available

Load-resistance

5 kg (11 lb)

1 kg (2.2 lb)

Frame

DSX-UF

DSX-TF

Z-axis stroke

50 mm (manual)

Tilt observation

Not available

±90°

Tilt angle display

Not available

GUI

Tilt angle method

Not available

Manual, fix / release handle

Measurement

Standard

Basic interactive measurements

3D Line profile measurement and simple 3D measurements

2D Line profile measurements

Advanced interactive measurement, including auto-edge detection and auxiliary lines

Neural Network Labelling

Live AI

Offline EFI, Offline Panorama

Image enhancement filters

Optional

3D Analysis Application*

Count and Measure

Neural Network Training

Material Solutions

Auto edge measurement

Particle analysis

Sphere/cylinder surface angle analysis

Multi-data analysis**

*Requires PV-3DAA.

Display

27-inch flat panel display

Resolution

1920 (H) × 1080 (V)

System total

Upright frame system

Tilt frame system

Weight (frame, head, motorized stage, display, and console)

43.7 kg (96.3 lb)

46.7 kg (103 lb)

Power consumption

100 – 120 V / 220 – 240 V, 1.1 / 0 .54 A, 50 / 60 Hz

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.

Redirecting

You are being redirected to our local site.

Attention: Please enable JavaScript

Sorry, this page is not available in your country