Solutions for Machinery Processing (Automotive / Machined Parts Industries)

Solutions for Machinery Processing (Automotive / Machined Parts Industries)

More information is available on the application notes pages | When cutting, drilling, polishing, and milling metal parts, many types of small defects may occur. In order to produce parts that are high quality, scratches, cracks, pore size, and contamination must be strictly monitored during the production process. |

Welding Distortion

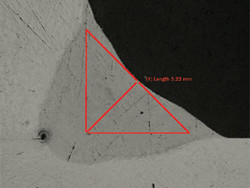

Weld measurement solution (A-Throat measurement in a weld seam) | OLYMPUS Stream offers an optional solution for measuring the geometric distortion induced by heat during welding. It is easy to perform asymmetry, multiple perpendicular lines, and A-throat measurements, and the solution enables detailed and quantifiable measurements of the welding distortion. These measurements are important for assessing the quality of the weld. |

Key features

| Typical applications

| Associated functions

|

Phase and ROIs Measurement

Advanced phase analysis solution (Phase analysis in dual phase polymer) | OLYMPUS Stream is used to measure multiple phases on a microstructure by selecting color or gray level intensity (threshold). Sixteen different phases can be defined as well as multiple regions of interest (ROIs) (including the magic wand). Several color spaces can be used (RGB or HSV) and minimal size criteria can also be defined. The results are then expressed as phase fraction area calculations. In order to create reproducible results, the ROIs can be defined using discrete sizes for comparative measurements. |

Key features

| Typical applications

| Associated functions

|

Particle Distribution

Particle distribution (Particles extracted on membrane filter) | Measuring the physical characteristics of particles is a common task in a wide range of industries and is often a critical parameter in the manufacture of many products. The Materials Solution Particle aDistribution classifies particle parameters based on their morphology such as size, diameter, area, color, and elongation and builds a graphical representation of the distribution. Class bins can be defined with color codes to better understand the results. |

Key features

| Typical applications

| Associated functions

|

Other Recommended Solutions

- Count and Measure

- Cast Iron

- Inclusion Worst Field

- Grains Intercept

- Grains Planimetric

- 3D