Background

Over the past decade, the aviation market has experienced a sustained period of significant growth. Global air traffic has risen at a steady rate, and commercial and military airplane manufacturers have undertaken several major programs (including the A350, A380, B787, and B777). This development has been consistent despite ever-increasing fuel prices and growing environmental concerns over emissions.

Performance demands on aircraft manufacturers and their suppliers have intensified. High fuel prices and an increased focus on the environment have led manufacturers to develop lightweight materials in order to build more efficient aircraft. Increased air traffic and the introduction of new airplane models has put pressure on the suppliers to maximize productivity, which can be achieved, in part, through faster inspection speeds.

High-speed inspection of composite parts is particularly difficult because of the complex geometries that are involved.

Problem

In production environments, manufacturers of composite parts are facing the challenge of having to inspect complex-shaped parts at very fast inspection speeds.

Complex Geometry Inspection

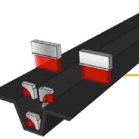

Composite parts often feature complex geometries that require full volumetric coverage, therefore requiring more advanced inspection techniques to be used.

Fast Inspection Speed

The constant increase in the production rates of commercial and military aircraft puts more and more pressure on the quality control process to be performed at higher speeds.

Solution

To meet these challenges, Olympus offers an integrated, nondestructive inspection solution comprising hardware (acquisition unit), multiple phased array probes, and dedicated software, all designed for high-performance inspection.

Multiple-Probe Configurations

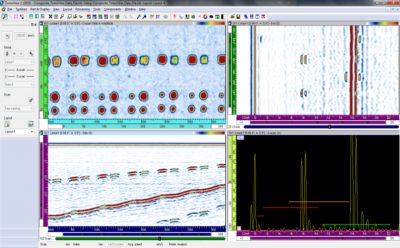

Multiple phased array probes are required to help ensure full volumetric coverage in a single inspection on complex-shaped composite parts. The FOCUS PX™ acquisition instrument has the capability to drive numerous probes and bring all the data together in FocusPC software, greatly simplifying the inspection process, reducing cycle time, and improving operator efficiency.

High-Performance Acquisition Unit

The FOCUS PX acquisition instrument enables you to build significantly faster and more efficient inspection systems by taking advantage of its high-end specifications.

- Scalability (use up to four FOCUS PX units in parallel)

- High pulse repetition frequency (PRF)

- High data throughput

- 5 gates with advanced synchronization capabilities

Powerful and Flexible Software

The FocusPC software is designed with powerful inspection and analysis features to take full advantage of the FOCUS PX unit’s capabilities and help ensure optimal system performance. FocusPC software can be easily integrated into typical industry software environments and offers multiple advanced composite inspection features.

- Signal-to-noise ratio (SNR) analysis

- Easy and precise delamination sizing

- Matrix filters

- C-scan merge

Scalability

The FocusPC software has the capability to drive up to four FOCUS PX acquisition units in parallel, enabling improved coverage and up to a threefold increase in inspection speed. Also, having all the inspection data from the multiple FOCUS PX units gathered in the customizable FocusPC software display helps to improve operator efficiency.

System Automation

The FOCUS PX software development kits (SDK) can also be used to automate the inspection process and build application-dedicated software, further improving cycle and operator efficiency.

Conclusion

Olympus’ advanced inspection technologies enable the development of high-performance inspection solutions that can be used to achieve full volumetric coverage on complex-shaped parts while helping ensure optimal inspection speed.