![]()

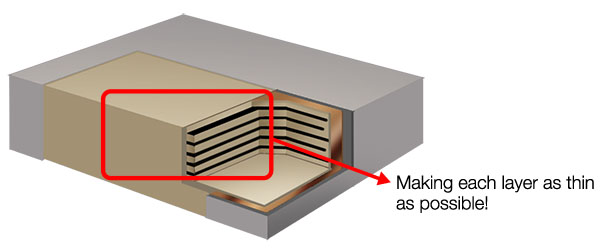

Image of a multilayer ceramic condenser

Application—Measuring Dielectric Thickness in a Multilayer Ceramic Condenser

What Is a Condenser?

A condenser is one of the important passive components incorporated into many electronic devices. Its basic property is instantaneous storage and electrical discharge.

The structure of a condenser comprises an insulator and two metal plates placed face to face on both sides. When voltage is applied on the metal plate, the positive and negative charges flow into the metal plate, but the insulator blocks the flow of the electric current. Although the positive and negative charges are attracted to each other, the electric charge is accumulated in the metal plates owing to the absence of a flowing electric current. The accumulation stops when the electric charge

builds up to the limit. The amount of electric charge accumulated up to the limit is called “capacitance.” The capacitance is determined by the metal plate size, distance between the metal plates, and insulator material.

Greater capacitance is associated with the following characteristics:

- Larger surface area of the metal plates, or “electrodes,” and a narrower distance between those plates

- Higher specific dielectric constant (ease of polarization into positive and negative electrical charges) of the insulators, also called “dielectrics"

When the conducting circuit is connected to the metal plates of a charged condenser, electricity is instantaneously discharged. Condensers also have the function of stabilizing the voltage of the electric circuit, which derives from their property of transmitting only an alternating current.

Another function of condensers is to eliminate the noise from an electric current, which is due to their capacity to easily pass high-frequency alternating currents.

Types of Condensers and the Rise of MCLLs

There are several types of condensers with the properties and functions mentioned above, which differ in their specific characteristics. For example, there are electrolytic condensers with high capacitance, film condensers with capacitance values that change with temperature variations, and small-sized ceramic condensers with high-frequency properties, etc.

Recently, multilayer ceramic condensers (MCLLs) have been attracting attention. Thanks to the realization of condenser technology that enables them to handle large capacities by increasing the number of laminated layers of electrodes and dielectrics, MCLLs have found widespread use in applications ranging from mobile terminals to automobiles. Moreover, it is expected that large quantities of MCLLs will be incorporated into 5G devices that are set to spread throughout the world. This will lead

to increasing demand for MCLLs with smaller sizes and larger capacities.

Necessity to Make MCLL Layers as Thin as Possible

As mentioned above, the capacity of a condenser is proportional to the surface area of its electrodes, and inversely proportional to the width of the dielectrics. Accordingly, MCLLs, which are small in size but large in capacity, require thin electrode and dielectric layers to achieve the desired performance.

Conceptual figure of a multilayer ceramic condenser's interior

Currently, the thickness of each electrode and dielectric layer is estimated at several micrometers, and managing such fine layer thickness is an important part of the quality control process. For this purpose, it is necessary to measure layer thickness at microscopic-level resolution.

Measuring the Thickness of Condenser Electrode and Dielectric Layers Using the DSX1000 Digital Microscope

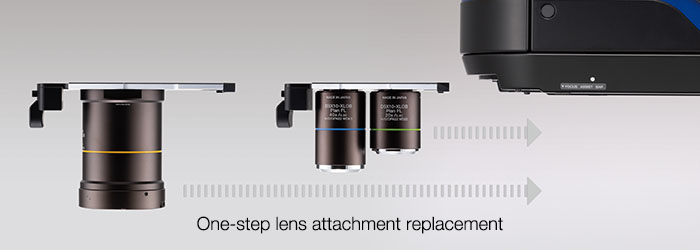

[1] Rapid Switching between Macro and Micro Magnification

To measure the thickness of the electrodes and dielectrics within the MCLL, the first step is to get an overview of the portion that is likely to need measurement. This overview is carried out by viewing a wide field at low magnification. Once you decide on a site to measure, you can then switch to a magnification suitable for measurement. It is common to first increase magnification by zooming in and, depending on the sample, it may be possible to perform measurements by zooming in up to a

certain level of magnification. However, while zooming increases the magnification, it does not improve image quality. In other words, you will not be able to see what you cannot see.

Since improving the image quality depends on the resolution of the objective lens, if the magnification used for measurement differs greatly from the magnification used during the overview, you will need to change the objective lens. With many conventional digital microscopes, you need to disconnect and reattach the camera and cables when replacing the objective lens. This often results in the inconvenience of losing the selected measurement

site.

Olympus' DSX1000 digital microscope, in contrast, lets you mount up to two objective lenses on the zoom head at the same time. This means you can easily switch between the front and rear objective lenses by simply sliding them forward or backward, without losing your measurement site.

Similarly, when replacing one objective lens with another that is not currently attached, you can do so just by sliding the attachment holding the lens into place in the head. As a result, your field of view stays at the measurement site.

Of course, the unit comes equipped with an electric optical zoom with a zoom ratio of 10x, making it easy to change the magnification by rotating the control knob on the console.

With this combination of functionalities, the Olympus DSX1000 digital microscope makes it easy to choose a wide range of magnifications with high resolution.

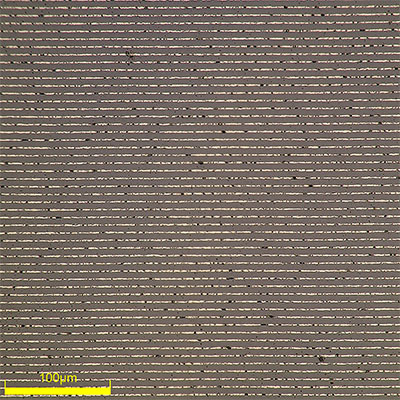

Get an overview of the position you want to measure at low magnification (700X)

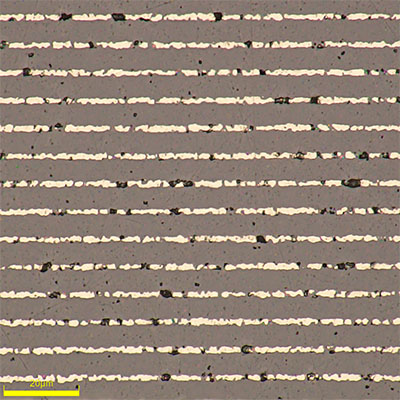

Once the measurement area is set, increase the magnification to a suitable level for measurement (2500X)

The interfaces between the dielectrics and electrodes are clearly visible.

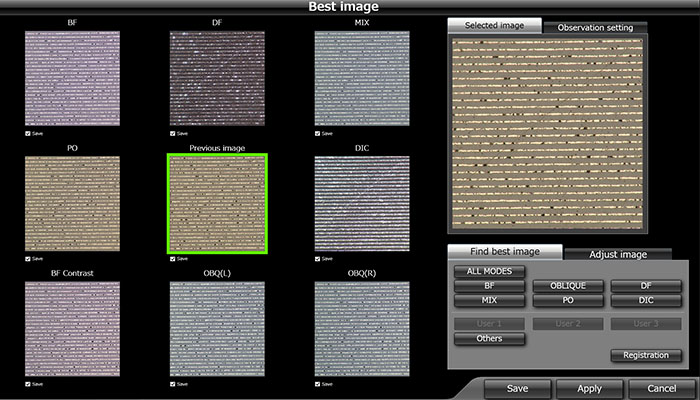

[2] Select the Optimal Observation Method by Comparing Images—Multiple Preview Function

The microscope features various observation methods. For a person who is not familiar with microscopic observation, it is not easy to immediately select the most convenient method for observing the lamination state of the electrodes and dielectrics in an MCLL. But the DSX1000 microscope can present sample images acquired using all the observation methods simultaneously on the screen. All you need to do is choose the image that is easiest to observe, and the microscope switches to the corresponding observation method. This means anyone can immediately perform measurement and analysis without wasting time thinking about the observation method.

Example of a multi-preview image

For this multilayer ceramic condenser's cross-sectional sample, polarization provided the clearest image.

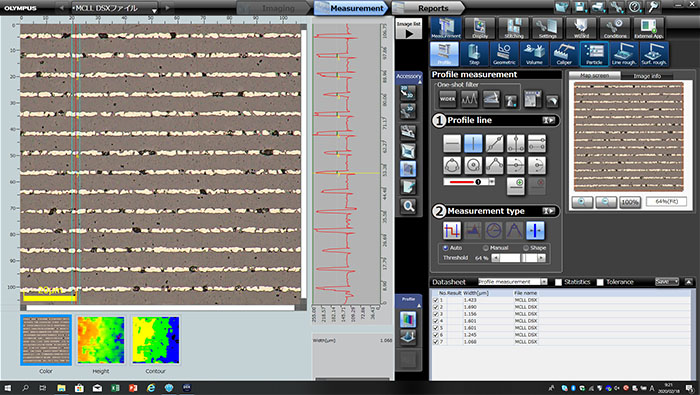

[3] Measurement Screen Offers Versatile Viewing Options to Facilitate Analysis

Electrode layer thickness measurement screen

The electrodes and dielectrics differ from each other in the color tone contrast.

Displaying this difference with a profile enables you to measure the thickness of the electrode and dielectric layers and perform any number of measurements at any position.