Videoscopes enable users to visually inspect areas that are hard to access and some even enable inspectors to measure the size of flaws they encounter. Recent technological advancements have increased the precision of these measurements, even when taking measurements from farther away.

Super Wide Stereo

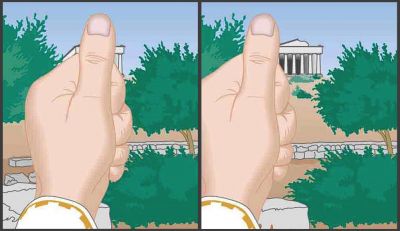

Stereo measurement functions similar to how our own depth perception works. Our brain is constantly calculating distance based on parallax (change in position from one image to the other). Looking at the images below, our brain knows that the building has not moved even though the object appears to shift from one eye to the other. This shift is inversely proportional to distance. The closer something is, the more dramatic the difference is between your eyes. This means that we can directly measure how close an object is based on how much it changes position from one image to the other.

|

| Parallax left eye (left) and parallax right eye (right); image demonstrates lateral shift. Source: https://slideplayer.com/slide/7323922/ |

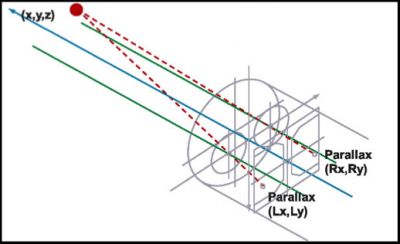

Videoscopes use the same fundamental principles to make measurements. Instead of a brain and two eyes, videoscopes use a CCD imaging sensor and processor and lenses in a scope tip adaptor. The tip adaptor has two lens systems that are a known, fixed distance from each other, and the parallax is used to determine the distance of an object.

|

| Parallax in a videoscope tip adaptor. |

Super Wide Stereo

Our IPLEX® NX videoscope features super wide stereo measurement, meaning it has a larger depth of field (DOF) and field of view (FOV) so defects can be measured from farther away. The measurement range of previous models was 0.2 in. to 1.2 in. but, with super wide stereo, you can measure from 0.15 in. to 2.3 in. The result of these enhancements is that you can measure 4X more than what was previously possible.

While the ability to measure larger flaws is helpful, super wide stereo provides users with another important benefit — speed. It can take minutes to position a videoscope to get a reliable measurement. Since the IPLEX NX videoscope can measure defects from almost twice as far, inspectors spend less time making measurements.

Overcoming Challenges in Measurement Accuracy

Stereo measurement relies on the selection of two pixels — one chosen by the user and one chosen by the videoscope on the alternate stereo image. For example, if I held a piece of string 2 feet in front of you, you can estimate its length down to an accuracy of ½ to ¼ of an inch. If I held a piece of string 50 feet from you, you could only estimate the length down to an inch or two. The same fundamental issue is inherent in any visual measurement system.

There are two ways to compensate for this inherent distance issue. The first way is to use 1 to 1 matching. While we pride ourselves on manufacturing high-quality lenses, we will never be able to make a perfect lens system. Variations occur from stereo tip to stereo tip. That’s why it’s important to calibrate your stereo tip to the videoscope it’s being used with. The calibration finds variances and incorporates them into the measurement algorithm, improving accuracy.

The second way to compensate is to improve the scope’s ability to pick the correct matching point. Videoscope technology is now so advanced, that the precision of point matching is no longer limited by pixel size. Pixel sizes have gotten so small that quantum mechanical effects, such as airy disk and diffraction patterns, have more to do with being able to see and pick the right point in a stereo measurement image. If a scope has smaller pixels but the image is not sharp on the CCD, the point you care about can span multiple pixels. Because of incredibly small pixel sizes, we are in a post-pixel-count era where the quality of the lens system has become even more important to a videoscope’s measurement precision.

Conclusion

With super wide stereo measurement and outstanding resolution, it’s now possible to make more precise measurements from farther away with a videoscope. This helps inspectors save time and, in turn, reduce cost.

Get In Touch

.jpg?rev=2D3E)