Many industries increasingly use austenitic welds and welds containing dissimilar weld materials. These welds can be used to create components with improved or tailor-engineered properties. For example, a part may need high temperature resistance in one area and good corrosion resistance in another. Other structures may need a combination of toughness or wear resistance in one location and high strength in another location.

The inspection of these types of welds with ultrasonic phased array technology is associated with challenges relating to the changes in density and acoustic properties of the materials (anisotropy). This guide provides an easy stepby- step overview of the points to consider when carrying out ultrasonic (UT) inspections of austenitic or dissimilarmaterial welds. It also shows how Olympus’ comprehensive range of flaw detection products – such as the FocusPX, the OmniScan and phased array probes and wedges – can be used to facilitate the inspection process.

Introduction

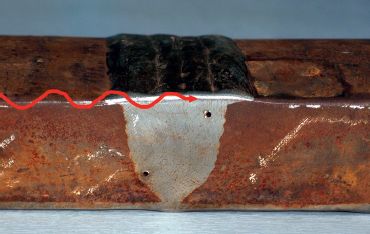

Industrial sectors such as the oil and gas and power generation industries frequently use pipelines where a carbon steel pipe is cladded with a corrosion-resistant alloy (CRA); these same alloys can also be used as a filler material for girth welds (figure 1). These interfaces, as well as many other types of dissimilar-material welds, can present a problem in non-destructive testing (NDT) and are traditionally inspected using radiography. However, the use of radiography is associated with long exposure times and potentially harmful radiation. These difficulties, as well as developments in the field of phased array technology make ultrasound an excellent alternative for these types of inspections.

|  |

Figure 1: Welding of Cladded Pipes

Containing a dissimilar weld material (left) and a weld used to join two different materials (right).

The Challenges of UT Inspection

Conventional UT is a successful and proven technique for carbon steel weld inspection. When inspecting a dissimilar weld material however, there are several aspects that make UT inspection more complex.

Metal-Metal Interface and Grain Size

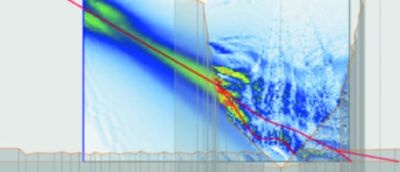

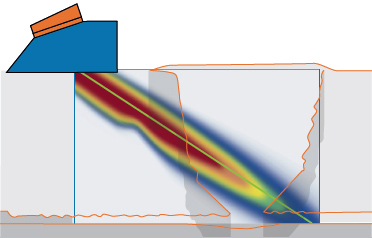

When a UT beam travels through a component containing a weld, both the metal-metal interface and the coarse-grained structure of the weld can cause reflection (backscatter) and refraction of the UT waves. This, in turn, will lead to skewing and attenuation of the beam (figure 2).

|  |

Figure 2: Distribution of Energy in Welds

In a weld containing a similar weld material (left) versus a dissimilar weld material (right). At the interface, skewing and attenuation of the UT beam occurs when using shear waves.

Optimizing the inspection of these types of welds involves considering the same variables as conventional carbon steel welds. However, these steps (A-D) have to be reviewed in detail to ensure adequate detection of indications. The most important steps are:

A) Scan planning

- Propagation mode – longitudinal vs. shear waves

- Transmit-receive longitudinal (TRL) technique

- Ensuring full coverage of the weld

- Electronic focusing and probe selection

- Instrument capabilities

B) Calibration

- Selection of the calibration block

- Wedge delay calibration

- Sensitivity calibration

- Detection level adjustment

C) Sizing and depth tolerance of indications

D) Coupling

The following sections will discuss each of these parameters – explaining common issues and providing advice on how to achieve fast and accurate results when inspecting challenging welds.

A) Scan Planning

Propagation Mode – Longitudinal vs. Shear Waves

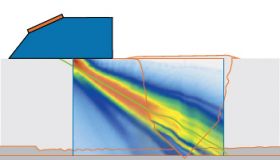

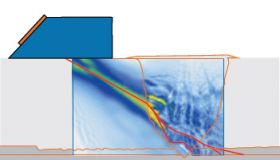

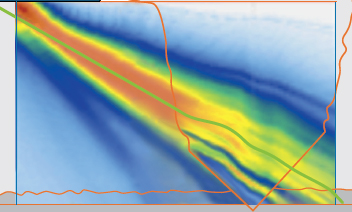

One of the main considerations when inspecting challenging welds is selecting the wave type for the inspection. When scanning a weld, longitudinal waves show a better transmission of the energy of the UT beam than shear waves. Modelling the effect of the propagation mode on the UT beam (figure 4) shows that the beam undergoes a higher degree of skewing when shear waves are used. Therefore, despite potential interference from reflected shear waves, longitudinal waves are recommended for inspection of dissimilar weld materials.

|  |  |

Figure 4: A Computer Model of Different Wave Types

2.25 MHz longitudinal waves (top), 1 MHz shear waves (bottom left) and 2.25 MHz shear waves (bottom right) in a pulse-echo configuration showing that the material has a greater negative effect on the quality of the beam when using shear waves (as shown by the irregular shape of the red line).

Reducing Noise with the Transmit-Receive Longitudinal (TRL) Technique

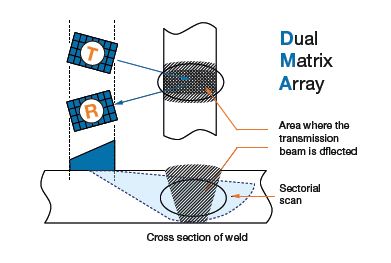

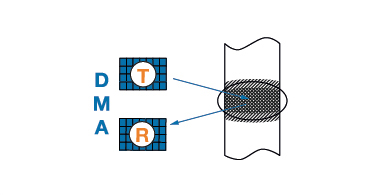

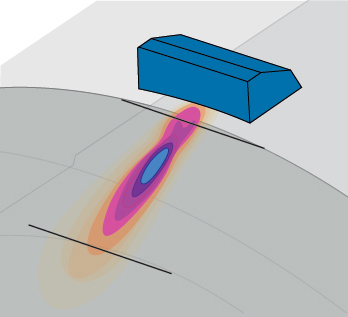

The next decision to create the best inspection setup is whether to use one or two transducers. Weld inspections can be carried out using either two separate transducers for transmitting and receiving, or using the same transducer. Due to the high noise levels generated in these challenging components, a one-transducer approach (also known as the pulse-echo technique) is not optimal and so the TRL technique (with two transducers) is recommended.

The TRL technique can be run using conventional UT transducers as well as phased-array probes. The benefit of using phased-array is that sectorial scans can be used, offering imaging capabilities and allowing easy coverage without moving the probe back and forth. These capabilities, combined with better control over the UT beam, simplifies inspection for improved detection capabilities, even if, in some cases, multiple distances between the probe and the centre line of the weld might be required to offer the best orientation of the beam versus the indications to be detected.

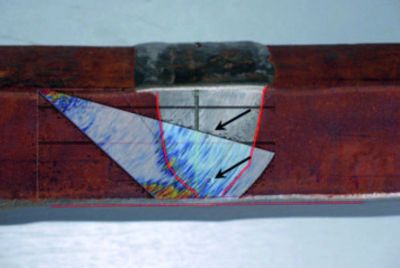

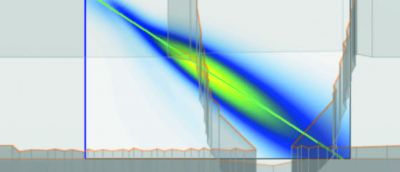

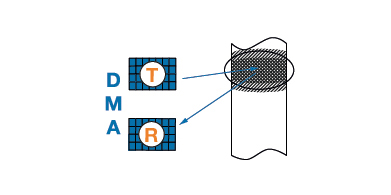

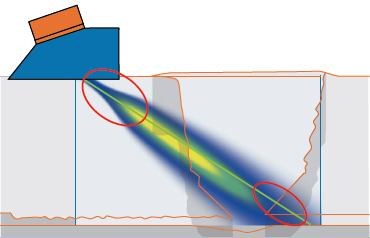

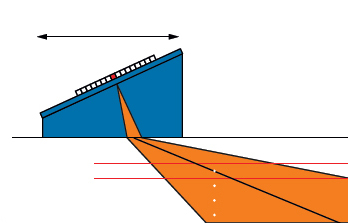

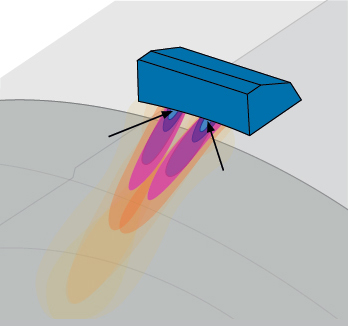

A consequence of the TRL technique is that the volume in which a signal with sufficient energy can be obtained is reduced. Figure 9 clearly shows the region of the resulting energy of the TRL technique at the crossing point. Compared to the pulse-echo technique, the energy is much lower in the region before the beams cross, as well as beyond the crossing area. Figure 9 also shows the reduced depth of field when using the TRL setup. In the area just below and between the two transducers – before the point where the beams cross – low or no energy is present, which means that sensitivity is poor. Beyond this crossing area, the energy is also reduced as it originates from the far field of each transducer. Due to the beam spread of each transducer, sensitivity at these depths drops off quickly. However, the area covered by the scan is still sufficiently large. In conclusion, TRL offers a reduced noise level compared to a pulse-echo technique. Thanks to a pseudo-focused beam, energy comes from the area of interest only, where the two beams cross each other. Furthermore, the low profile of the wedge also allows a short approach to the weld, which is favourable to sensitivity. |   Figure 7: The TRL Technique and DMA Probes |

Figure 8: DMA Probes and Curvature

A DMA probe (right) better compensates for the curvature of the surface of a component – a smaller focus point provides better sensitivity.

|  |

Figure 9: Pulse Echo Versus the TRL Technique

Model of the energy of a pulse-echo transducer (left) compared to the TRL technique (right) and the resulting energy of the transmitter and the receiver beam.

Inspecting the Surface and Ensuring Full Coverage of the Weld

Ensuring full weld coverage is critical when using the TRL technique. As shown in figure 9, there are limitations in the ability of the TRL technique to achieve a comprehensive weld inspection using longitudinal waves. Nevertheless, it is essential that the entire weld volume is covered.

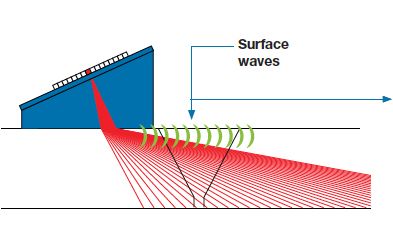

A drawback of using longitudinal waves is that shear waves are produced simultaneously (figure 10). This means that, because of different velocities, when longitudinal waves bounce off the bottom surface of the component, shear waves will interfere with the detection of the longitudinal waves reaching the weld and mainly its top area.

Internal cladding of a material that is different to the main component also limits the ability of longitudinal waves to bounce off the bottom surface (figure 11).

Because of the difficulties in inspecting the uppermost section of a weld with a longitudinal-wave sectorial scan, the nearsurface volume of the weld can be covered using surface waves (figure 12). Depending on the material, the structure of the weld and the probe parameters, surface waves allow inspection of the first few millimetres in front of the probe. If this distance is deemed sufficient, the inspection can be carried out without the need to remove the weld cap. However, when required, the weld cap must be flushed away and a second scan might be performed on top of the weld itself to ensure full coverage up to the centre line. |  Figure 10: Longitudinal and Shear Waves |

|  |

Figure 12: Wave Propagation Paths

Left, longitudinal waves (red) and surface waves (green). Right, surface wave propagation across the surface of the weld cap (red).

|  |

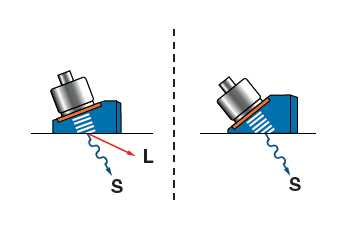

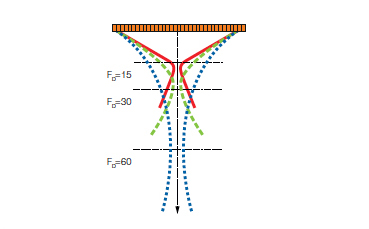

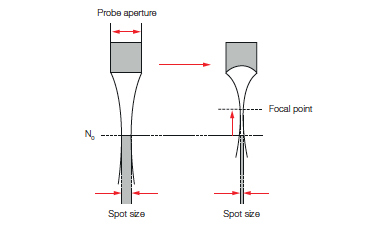

Figure 13: Phased Array Probe Focusing

Electronic (left) and mechanical (right) focusing of a phased array probe decreases the spot size and moves the focal plane closer to the probe.

However, when a thicker component needs to be inspected, it is not possible to lower the focal plane by electronic focusing. In this case it is necessary to use a phased array probe with a higher probe aperture. There are two ways to increase the size of the probe aperture, which can be used individually or in combination; these two methods are:

- Increasing the size of the individual elements. This method does not require more powerful equipment to drive the elements, but probes with larger elements offer limited ability to steer the beam. Good beam-steering capability is required to perform a good sectorial scan and cover the weld volume in the best possible way.

- Increasing the number of elements used to carry out the scan. This way an inspector can reach greater depths without compromising beam-steering ability and accuracy. However, the electronic equipment used to drive the elements needs to have sufficient capability to handle the higher number of elements – an active aperture of 16 elements might not be enough.

Instrument Capabilities

When a weld is inspected from both sides, the phased array instrument needs to be able to drive several probes simultaneously for a single-pass inspection. In this case a 128-channel phased array instrument is often required.

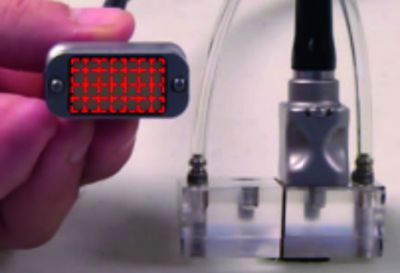

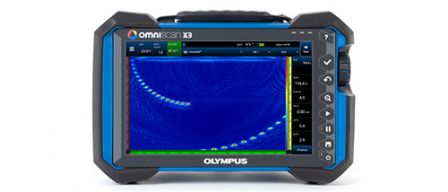

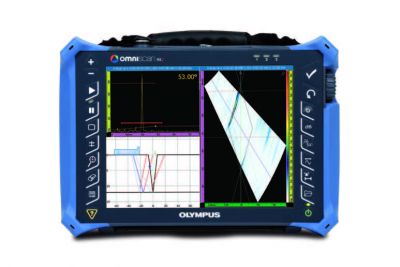

To meet these challenges, Olympus has developed a range of phased array instruments and probes that facilitate inspection of complex welds and provide the confidence to guarantee safety and durability. For inspection of components with a thickness of up to 25 mm, a typical DMA probe can be used (frequency 4 MHz). For deeper inspections, or for inspecting welds with a larger grain size, adequate wave propagation can be challenging. In this case, a probe with a lower frequency (1.5 MHz or 2.25 MHz) and a larger active aperture might be required. All probes can be driven by both the FocusPX and the OmniScan 32:128PR (figure 14).

|  |

Figure 14: Olympus’ FocusPX and OmniScan MX2

Two instruments that can drive DMA probes.

B) Calibration

Selection of the Calibration Block

Once the right combination of phased array equipment has been selected, a suitable calibration process must be decided. Calibration is an essential element of UT inspections and the first important consideration is the selection of a suitable calibration block (figure 15).

Two main parameters must be considered when selecting a reference block; the sensitivity of the calibration and the repeatability of the inspection:

- Sensitivity means setting a reference level according to a well-known indication (usually a side-drilled hole) present in the calibration block that can be compared to a real indication.

- Repeatability means that two inspectors, using the same inspection procedure, should produce the same report. It also means that the selected calibration block can be duplicated consistently for different operators.

Figure 15: A Calibration Block for UT Inspections

The two main options for a calibration block are:

- A reference block made of the parent material only, without any weld.

- A reference block made of a production weld, similar to the one to be inspected.

Although more representative of an actual inspection, a reference block containing a real weld has several important drawbacks, mainly regarding repeatability:

- The inhomogeneous weld material can attenuate UT energy and generate different levels of scattering at different positions in the weld.

- Waves generated at different angles cannot travel through the same quantity of weld material.

- The detection sensitivity of indications might vary when drilled at slightly different depths.

- Different beams generated at different angles can have a different velocity.

- If two equal calibration blocks are required, the attenuation might differ from one block to another due to variation in the manufacturing process.

It is possible that as a result of these issues, repeatability cannot be ensured, which means that the sensitivity level also cannot be guaranteed. When a reference block is made of the parent material only it becomes easier to create two blocks that have exactly the same properties, such as attenuation and velocity. It also ensures that the sound paths are the same and therefore have a similar attenuation.

Wedge Delay Calibration

When a wedge is used to generate angled beams, the whole setup must be calibrated. The wedge delay calibration can be kept similar to a standard pulse-echo inspection; a reference block containing well-defined reflectors can be used.

Sensitivity Calibration

In most cases, two sensitivity calibrations are carried out: one for the longitudinal waves covering the main volume and one for the surface waves covering the upper (near-surface) part of the weld. Once the repeatability of the calibration has been ensured by selecting a suitable calibration block, sensitivity calibration can be performed. This can be done, either using a fixed gain or using a time-corrected gain (TCG), which requires scanning side-drilled holes at different depths. With carbon steel welds, preparation of the TCG calibration is straightforward. It allows a sensitivity calibration, for example through scanning side-drilled holes (figure 16). With inhomogeneous and attenuative materials, preparing the TCG might be difficult when using a different technique than the pulse-echo technique. The different side-drilled holes can be reached with different sound paths, with different attenuations, resulting in differences too large for the gain required for each reflector.

If no TCG is used, one reflector – located on the weld bevel for example – can be used as a reference. However, when TCG is required and the depth of field (length of area where energy is high enough – see figure 17) is reduced as a result of using the TRL technique, preparing the TCG might be difficult. This is because the gain required to fully compensate the entire UT beam might be too high. The number of TCG points must always be limited to the useful area of each UT beam and the angles of the sectorial scan. There is no need to consider very deep TCG points for high angles as the beam will never cover these deep areas of the weld.

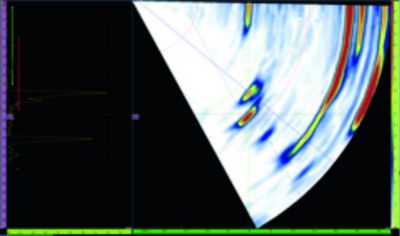

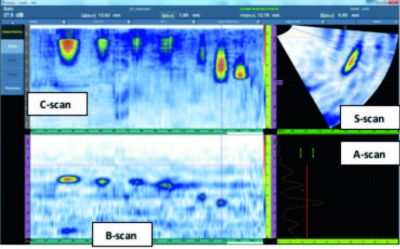

For the surface wave calibration, the setup is simpler; a notch in the outer diameter (OD-notch) is used and is set to 80% amplitude with different distances between the notch and the probe. Detection Level The gain needs to be adjusted to ensure that the noise level is kept to a minimum so that the different imaging modes – such as S-scan, B-scan and C-scan views – provide the easiest possible detection (figure 19). It is important to create scans with the best possible signal-to-noise ratio, as this will lead to clearer images and facilitate the analysis process. |  Figure 16: TCG Calibration |

C) Sizing and Depth Tolerance of IndicationsSelection of the Calibration Block |  Figure 17: The limited area where TCG can be applied. |

Figure 19: The Gain Level Should Be Adjusted to Ensure Clear Images |  Figure 20: UT Beam Deviation Computer simulation showing how a material can cause deviation of the UT beam. |

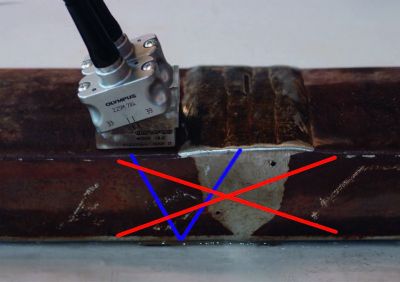

D CouplingA final consideration when determining an inspection protocol is the issue of coupling. With the TRL technique, the wedge holds two probes generating two UT beams. This means that there are two different exit points located at different areas on the wedge (figure 21). Consequently, the inspection can be more sensitive to coupling issues. Careful attention must be taken to avoid air bubbles between the two probes and the component. This can be done using either a manual or an electric water pump. |  Figure 21: The TRL Technique and CouplingeWith the TRL technique, there are two exit points (black arrows) that need good coupling as opposed to one single point for the pulse-echo technique. |

Conclusion

Ultrasound technology can be used for fast and detailed inspection of even the most challenging welds. However, many considerations regarding the techniques, equipment and calibration need to be addressed to ensure a successful inspection procedure. As with any inspection method, it is important to understand the limitations of the technique and to adjust the procedure accordingly. This guide has given an overview of the challenges and the considerations associated with a structure that is particularly difficult to inspect – the dissimilar-material weld.

In recent years, inspection professionals working in many different industries have demonstrated the clear benefits offered by Olympus’ integrated, off-the-shelf phased array instrumentation (FocusPX, OmniScan MX2), phased array probes and software. When the potential issues – as described in this guide – are adequately addressed, the TRL technique using DMA probes can bring precision and confidence to the inspection process.

Everywhere where coarse-grained materials are used – for example liquefied natural gas (LNG) tanks with 9% nickel welds or cladded components like pipes or vessels used in the power generation industry – UT inspection offers an excellent alternative to radiography, which often requires high-energy radiation and long exposure times, generates waste and poses security issues. UT inspection can increase productivity and avoid harmful radiation, while still preserving a very high detection level and excellent sizing capability.