Summary

In nondestructive evaluation (NDE), or nondestructive testing (NDT), many codes allow inspectors to substitute one inspection method with another, as long as certain requirements are met. Additionally, non-code-based inspection methods are constantly being reviewed to improve processes and reduce costs. Ultrasonic methods have become a popular and accepted substitute in inspections that previously employed radiographic methods.

Introduction

Radiography and ultrasound are complimentary NDT techniques. Both can volumetrically inspect welds and components for defects like cracks, lack of fusion, porosity, etc. The choice of one over the other often depends on external process decisions or small differences in the detection capability for a particular test. However, ultrasound has gained momentum as a replacement for radiography both in practice and in the codes of major organizations such as ASME (American Society of Mechanical Engineers) and API (American Petroleum Institute). Although most codes do not specify the ultrasonic method, phased array (PA) ultrasound, in particular, has become the most popular replacement method in inspection processes. PA is often also combined with time-of-flight diffraction (TOFD) when inspectors use acquisition units and scanners that can accommodate both methods simultaneously. In the past, code-based inspection processes typically followed code cases or appendixes. However, after increasing use and acceptance in industry, ultrasonic inspection processes are being added directly to the main body of major codes, for example, ASME Sec. V. Art. 4 from 2010 onwards. Phased array ultrasonic equipment is becoming more portable, affordable, and easier to use, making ultrasound a practical, safe replacement for radiography.

Typical Advantages of Ultrasound (over Radiography):

- High probability of detection (POD), especially for cracks and lack of fusion:

- Ultrasound tends to detect planar flaws better than radiography in most studies.

- Accurate sizing of defect height and fewer rejects or repair using Engineering Critical Assessment:

- Ultrasound permits defect height measurement, which enables volumetric consideration of flaw severity (instead of only flaw type and length).

- Does not emit radiation, does not cause hazards, and does not require additional licensing or personnel.

- Does not require screened-off areas. Work in proximity to ultrasonic testing can continue uninterrupted.

- Does not generate any chemical or waste material (as opposed to film-based radiography, which does).

- Real-time ultrasonic analysis of welds can provide instant evaluation and feedback to a welder.

- Setup and inspection reports are in electronic format (as opposed to film format in radiography).

Examples of Codes with Ultrasound Replacing Radiography

- ASME Code Case 2235

- ASME Code Case 179

- ASME Code Case 168

- ASME Code Case N-659

- ASME Code N-713

- API 620/650 App. U

- ASME Sec. V Mandatory Appendixes

Typical Ultrasonic Equipment and Inspection Requirements

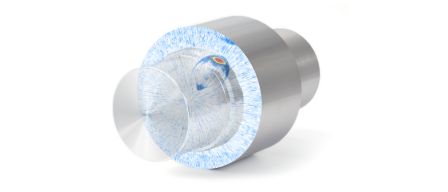

- An acquisition unit with full, raw A-scan data retention and position-encoding ability (for example, an OmniScan® flaw detector or FOCUS PX™ instrument).

- A scan plan and procedure that documents the inspection strategy and essential parameters (for example, parameters that are set up using the NDT SetupBuilder software).

- An industrial scanner (with position encoder) that can repeatedly scan a weld or component (semiautomatically or automatically):

- The choice of scanner model is based on the number of welds, pipe diameter, and other application variables.

- Deliverable data:

- The analysis is performed directly on the acquisition unit or using post-analysis with OmniPC™, TomoView™, or FocusPC PC software.

- Demonstrated performance of equipment, procedure, operator, and inspection process.

- Alternative acceptance criteria, as required.

- Probes, wedges, couplant delivery equipment, and other accessories.

- Proper training and certification of personnel.

The OmniScan MX2 (multi-group capable) [left] and OmniScan SX (single group) flaw detectors.

|  |

Fully automatic WeldROVER scanner (left) and semiautomatic HSMT-Compact scanner with an OmniScan MX flaw detector.

Conclusion

The replacement of radiography with ultrasound has become an industry trend, as well as a code-accepted practice. Easy-to-use and affordable portable phased array equipment and associated software are accelerating the use of ultrasound. The main reasons for this continuing trend include savings in process cost and time, improved safety of operators and others in surrounding areas, and the use of alternative acceptance criteria. The increased use of ultrasound has led to a decrease in part rejection and repairs.