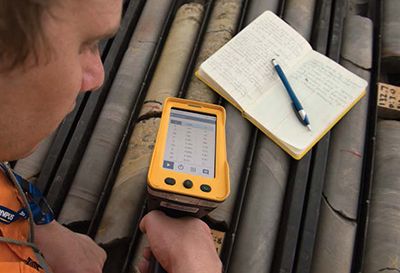

Olympus portable X-ray fluorescence (pXRF) analyzers provide high-performance, real-time geochemical data for rapid multielement characterization of soils, rocks, and ores. Recent major advances in pXRF technology have significantly reduced analysis test times and vastly improved the limits of detection and number of elements measured. Vanta™ analyzers are now routinely used in the identification of rock types using lithogeochemistry. They are also being integrated into standard geological logging activities (soils, drill chips, and core) because Vanta analyzers can instantly deliver objective chemical data at the sample location. These data can be used to classify and interpret rock types, alteration, and mineralization at the same time or even in advance of routine visual logging. |

Data-Driven Geological Logging with pXRF

With geological logging, a geoscientist makes visual observations to log the rock type, alteration, texture, structure, and other characteristics of a variety of samples including soils, chips, rocks, and cores. The geoscientist typically uses a logging chart (geological log) to record visual characteristics or paramagnetic features including color, grain size, texture, structural orientations, bedding, alteration, metamorphism, and cross-cutting. Geological logging is a fundamental skill acquired through years of theoretical study of rock and deposit collections followed by years of fieldwork observing geology in situ or using drilling samples. Only then is a geoscientist prepared to undertake detailed field-based logging campaigns studying the complexity and variation in geology around the globe. Consequently, an expression often used in the mineral exploration industry is: “The geologist who has seen the most rocks, wins!” Portable XRF and other analytical techniques are transforming the way we conduct modern, routine logging. The real-time delivery of objective logging information to geographic information systems (GIS), geological information management systems (GIMS), and 3D visualization and modeling packages is revolutionizing the industry. |

Visual Logging is Subjective

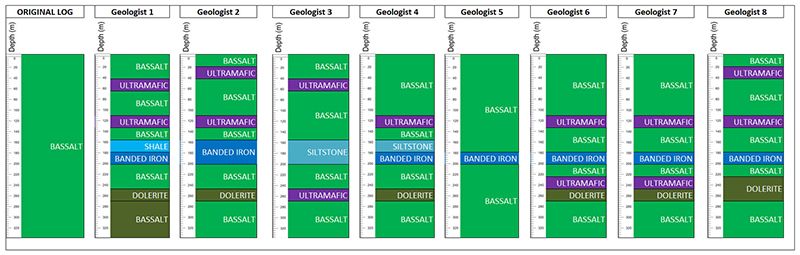

A major issue with visual geological logging is that every geoscientist has their own experience, opinion, and, idea of what rocks they are viewing. This situation creates complexity when combining data from multiple geoscientists on a given project. The subjective nature of visual observations is illustrated in figure 1, where eight geoscientists were given the same sequence to log. This resulted in seven different answers (geoscientists six and seven copied each other’s work).

Figure 1. Observations from 8 different geologists of differing experience on the same rock sequence

Laboratory assay data arrives well after the original geological logging has occurred, creating fundamental disconnect between the logging observations and the cross-referencing and validation with geochemistry. It can also lead to poor or delayed end-of-hole decisions (whether to continue or stop drilling) in the field and cause the drilling crew to be placed on standby or moved to a different location. This is where pXRF technology is adding significant value by delivering geochemical data in near real time.

Geological logging with a Vanta pXRF analyzer has many advantages, and adding the TERRA® portable X-ray diffraction (pXRD) analyzer provides even more:

- Objective data that can correlate seamlessly between locations or drill holes

- Aids in rock typing and identification

- Allows the geoscientist to connect the lithological observations to the geochemistry

- Make valuable and time-sensitive decisions (calling end-of-hole or extending)

- Lithogeochemistry and smart multivariate geochemistry can be applied to identify rock units, alteration, structural controls, and lithological boundaries

- Integrate data into algorithms or even machine learning routines to automate workflow

- pXRD data can complement pXRF by providing quantitative mineralogy

- Data can instantly be delivered, processed, charted, plotted, or displayed

- Observe data online, anywhere in the world

As with any analysis technology, pXRF requires fit-for-purpose application of the technology with appropriate sample preparation and presentation, QA/QC, and chain of custody in the same manner as with conventional laboratory data.

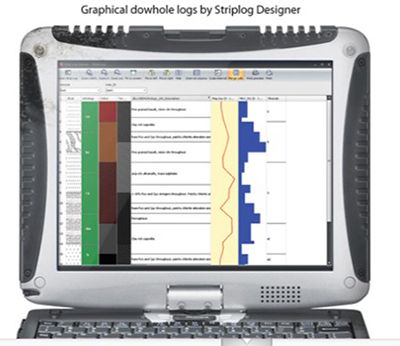

Figure 2 (below) illustrates the type of data that can be generated using an example of diamond drill cuttings from the Brukunga Pyrite Mine in South Australia and research work conducted by the Deep Exploration Technologies Commonwealth Research Cooperative (DET CRC) in Australia.

Figure 2. Digital drill-hole log of Bruknunga2 showing pXRF geochemistry and pXRD mineralogy derived from drill cuttings

Figure 3 illustrates the potential of using advanced algorithms (wavelet transform tessellation on iron ) to domain lithological features at three different orders of magnitude.

Figure 3. Wavelet transform tessellation applied to iron pXRF data downhole at Brukunga, South Australia

For more detailed information on the data in Figure 3, please refer to the following references: Uvarova, Cleverley Baensch. (2014). “Coupled XRF XRD analyses for rapid and low-cost characterisation of geological materials in the mineral exploration and mining industry.” AAG Explore Newsletter # 162. Hill, Robertson Uvarova. (2015). “Multiscale hierarchical domaining and compression of drill hole data.” Computers Geosciences 79, 47–57.