无损检测解决方案

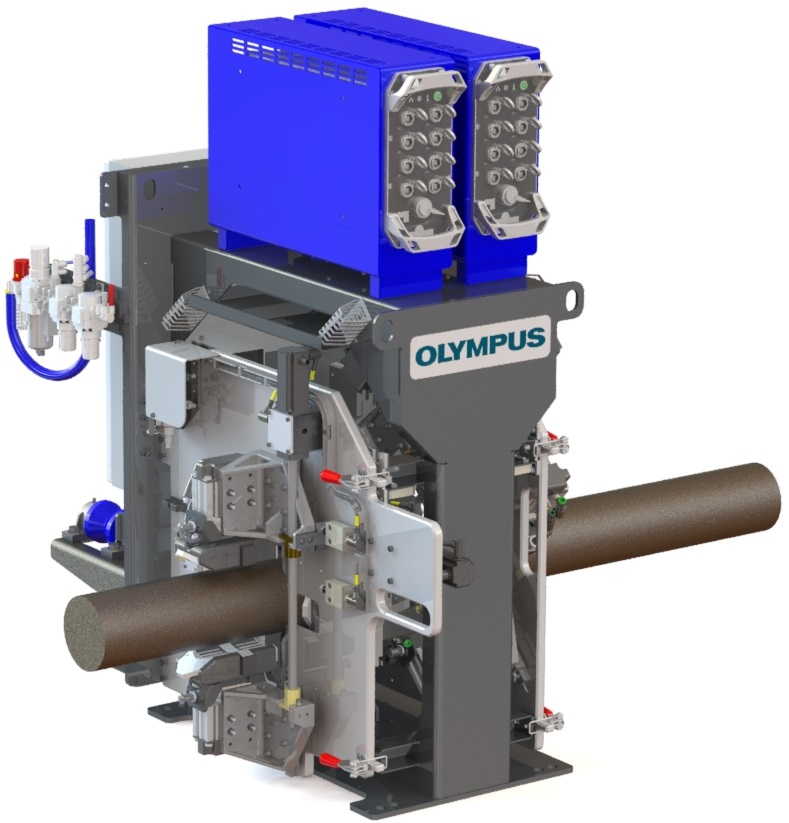

棒材检测系统(BIS):涡流阵列

Loading...

概览

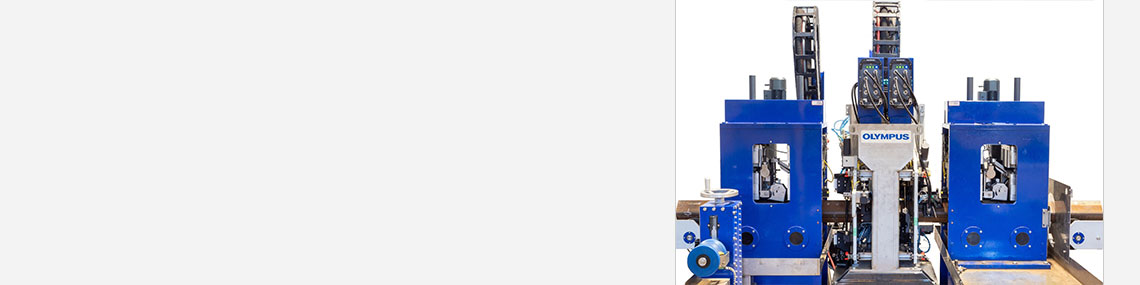

The BIS-ECA is a fully automated turnkey inspection system that is integrated into the metal production line to monitor safety and quality requirements of raw materials in both round and square forms.

ECA for Surface Inspections at High Speed

Eddy current array (ECA) is an effective and efficient inspection method, and the BIS ECA is a robust and flexible system built to meet the demands of metal processing plants:

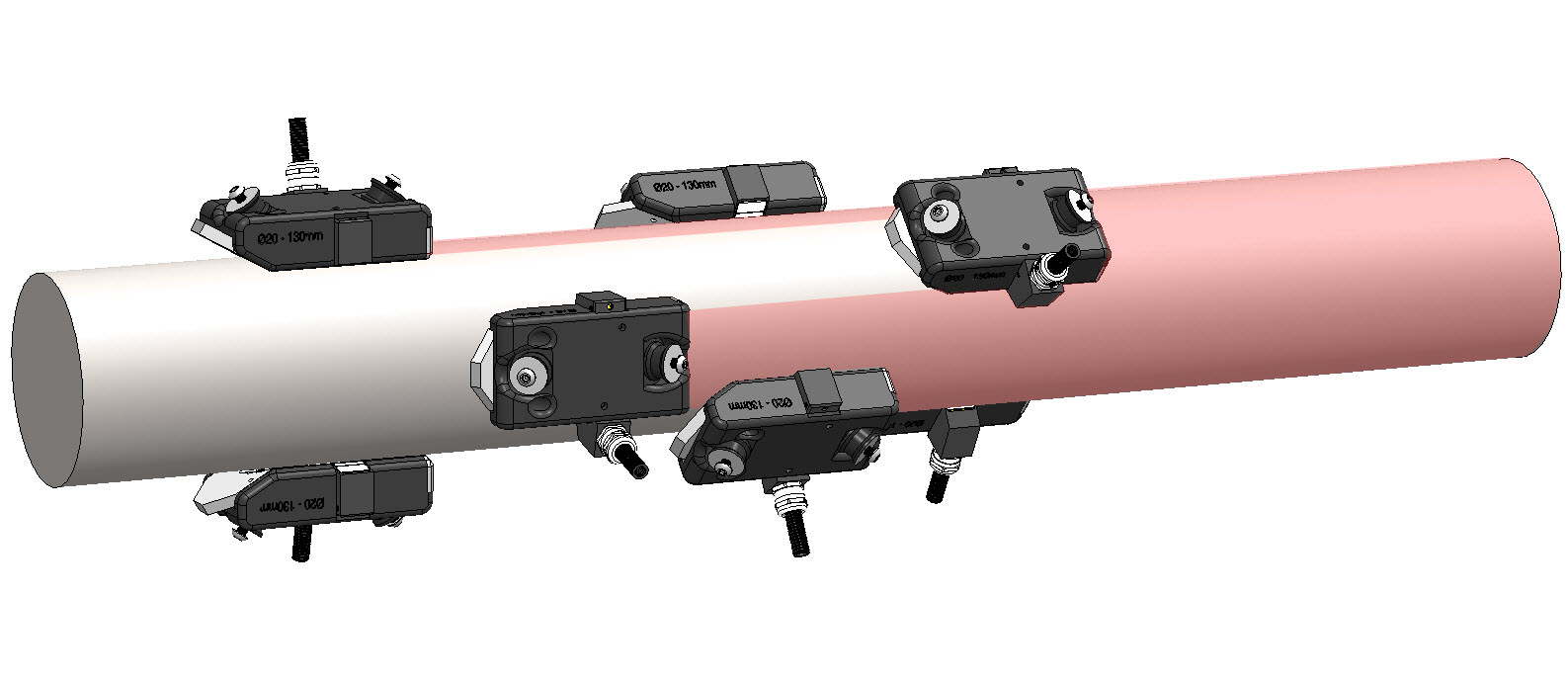

- Actuators automatically adjust the probe positions to the desired product size and adapt to surface or shape irregularities

- A single set of probes can cover the complete product size range

- Printed-circuit board (PCB) and patented Dynamic Liftoff Compensation (DLOC) technology simultaneously process

- Both axially and radially oriented flaws (up to 10 mm long surface cracks in 0° and 90° orientations) are reliably detected over the product’s entire surface

- Wear-resistant shoe with carbides and a protective hard-ceramic layer on the probes withstand shocks and abrasion from the surface

- Runs at continuous production speeds of up to 2.5 m/s with minimal operator intervention

- Small footprint makes it easier to integrate or retrofit into production lines

Full, single-pass inspection coverage on bars of different dimensions and shapes

Easy Operation, Increased Uptime

The simple and rugged BIS-ECA is designed to save time and operational costs for metal processing plants:

- Nonrotating, pass-through design reduces mechanical complexity

- Quick changeovers between product types and sizes

- Minimal maintenance required

- Rugged probes and wear shoes are designed to need servicing no more than once a year under typical inspection conditions

规格

System Performance

| Standard Product Range | Volume |

T2 system: 20 mm–130 mm (0.79 in.–5.12 in.), 1.5 m (5 ft) approximate minimum length

T4 system: 40 mm–260 mm (1.57 in.–10.24 in.), 3 m (9 ft) approximate minimum length |

| Speed | Up to 2.5 m/s (492 ft/min) | |

| Coverage |

Surface inspection using a multi-layer probe arrangement

Round: 100% of circumference Square: 100%, which includes faces and corners | |

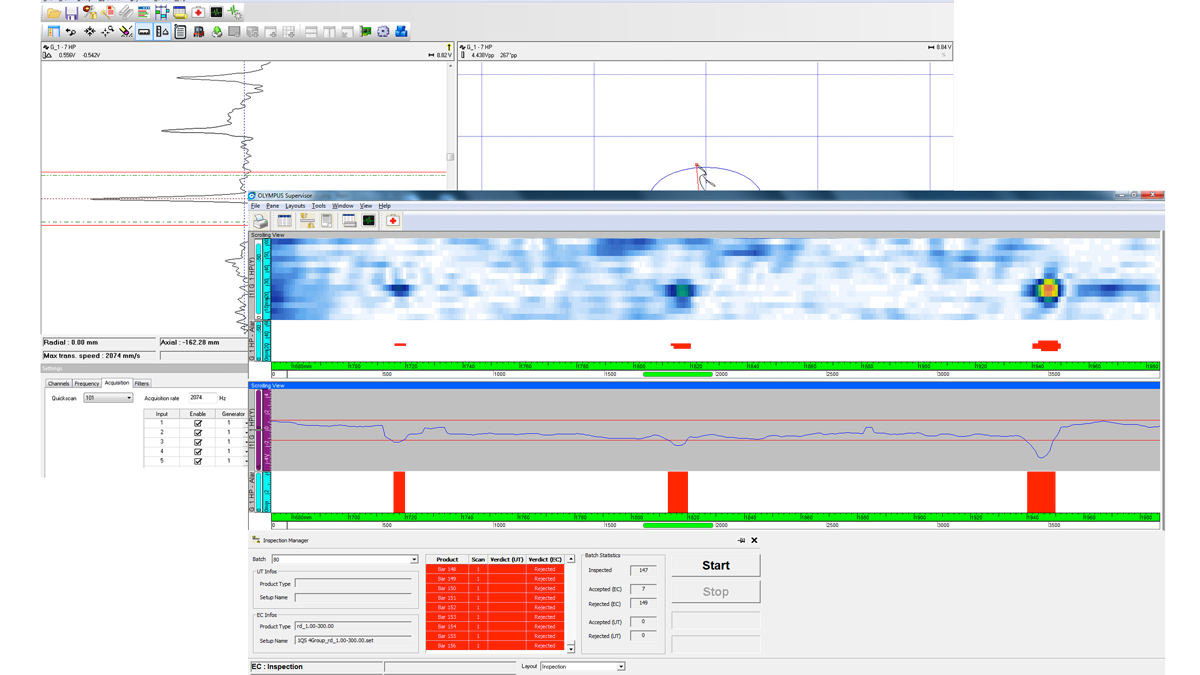

| Data Presentation |

Real-Time Data

Inspection Results | C-scan, strip charts, Lissajous (XY) layouts, and alarms |

| Inspection Modes | Orientation | Axially (0 degree) and radially (90 degree) oriented indications |

| Bar Temperature | Up to 70 °C (158 °F) | |

| Detection Capabilities for Typical Reference Defects | Size |

Surface crack size ≥0.2 mm (0.008 in.) depth × 10 mm (0.39 in.) length

Note: Minimum indication depth varies according to surface roughness and material grade |

| Reporting and Data | Report Types | Setup, calibration, calibration-check, inspection, user-configurable reports |

| Storage | Storage | Storage Real-time database inspection data storage—on local computer or end-user database |

资源库

Rozwiązania

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.