FOCUS PX / PC / SDK

概述

Phased Array Instrumentation Designed for Demanding Inspections

| Olympus offers a complete advanced phased array integration solution that meets the requirements of your most demanding customers. The solution includes the FOCUS PX, a powerful and scalable acquisition unit; FocusPC, a powerful data acquisition and analysis software program; and three software development kits (SDK), FocusControl, FocusData, and OpenView SDK, to customize your software interface based on your application and control FocusPC for a fully automated inspection solution. |  |

FOCUS PX Instrument

Excellent Signal QualityThe FOCUS PX provides excellent phased array signal quality using the latest Olympus technology, resulting in significantly improved signal-to-noise ratio. | Up to 12 dBSNR improvements | Up to 4dedicated UT channels |

Fast ProgrammingThe optimized FOCUS PX communication process significantly reduces programming time, resulting in minimized cycle time and improved operator experience.

|

Up to 40 °Coperating temperature | Rated IP65 |

Easy Integration

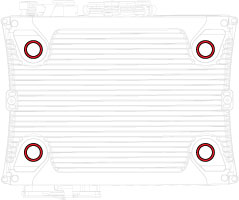

The FOCUS PX bumpers can be easily removed to access four screw holes for mounting the unit directly onto a scanner or inspection system.

Simple Cabling Multiple FOCUS PX units can be synchronized with each other through a simple cable configuration. This allows all I/O signals to be received by one unit, reducing cabling and greatly simplifying the overall integration. |

Easy Mounting Easy and quick installation allows the FOCUS PX to be positioned much closer to the probes, reducing cabling and optimizing signal quality. Four screw holes are available for mounting the unit directly onto any inspection scanner. |

WeldSight软件

Advanced PAUT Weld Inspection Software

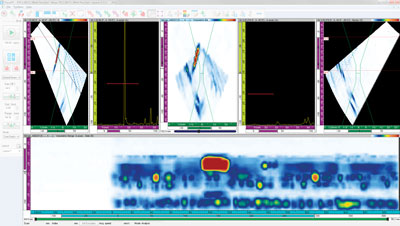

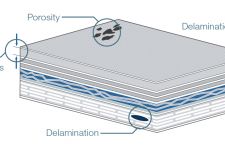

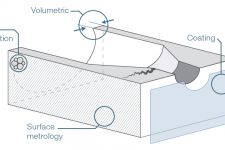

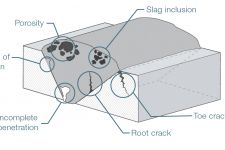

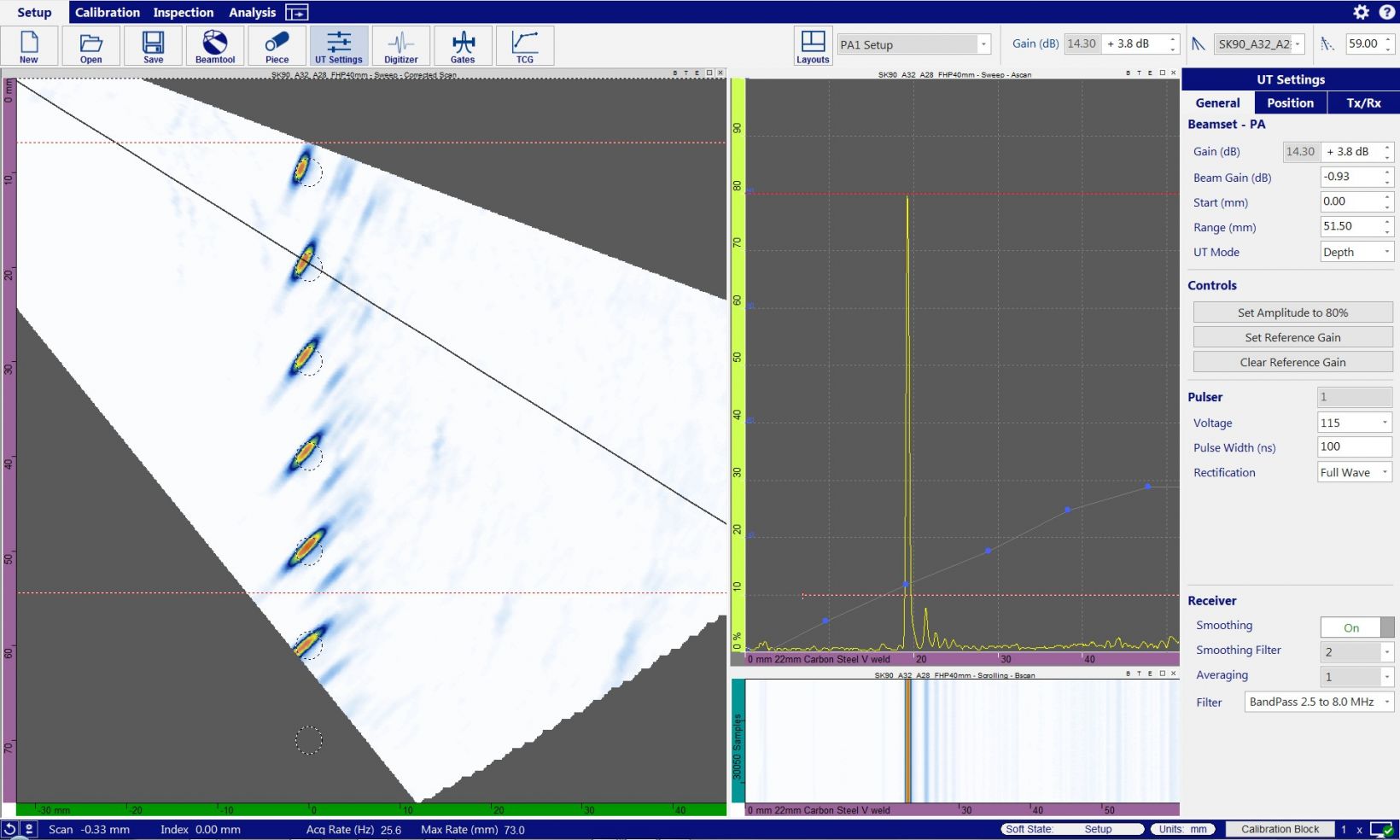

Engineer compliant and repeatable advanced phased array (PA), ultrasonic (UT), and time-of-flight diffraction (TOFD) weld inspection with WeldSight™ software’s comprehensive acquisition and analysis tools.

Efficient WorkflowWeldSight software features a logical, streamlined workflow:

|  |

Advanced Software Functionalities

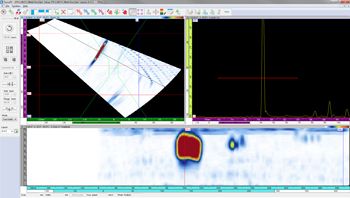

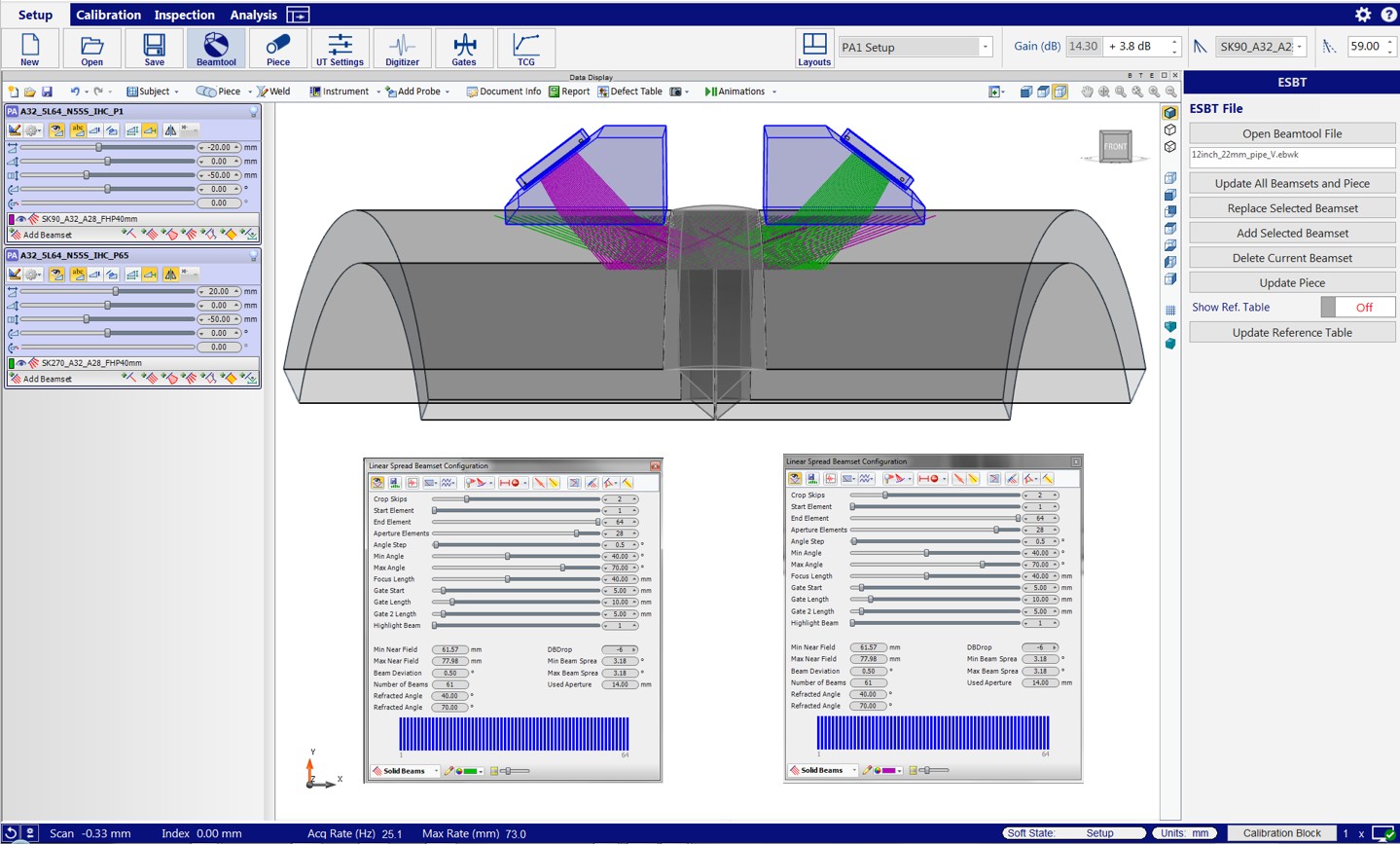

Designed for fabrication (manufacturing) or demanding in-service (maintenance) welds, WeldSight software contains the necessary tools to engineer advanced phased array inspections and analysis.

• Fully integrated BeamTool scan plan designer from Eclipse Scientific

• Automatic wedge validation and probe element validation

• Autofocusing of targets

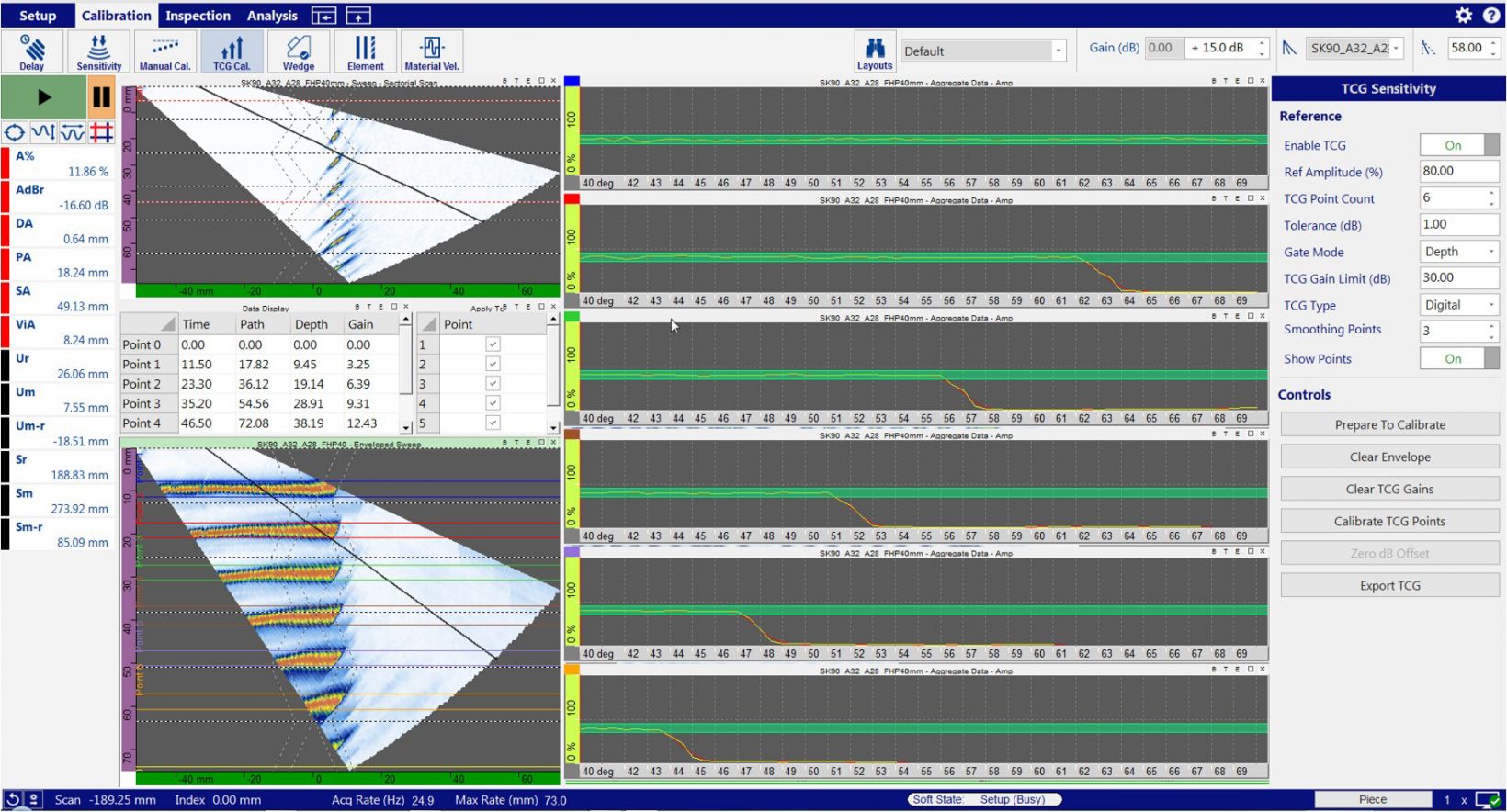

• Improved time-corrected gain (TCG), enabling simultaneous calibration of multiple points

|  |

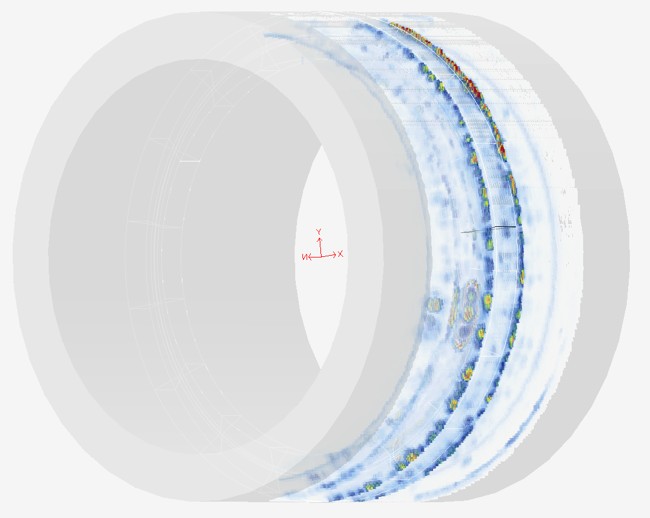

| • Drag-and-drop customizable displays • TOFD tools • Dynamic C-scan merge views • 3D imaging and polar view •Dual Linear Array™ (DLA)/Dual Matrix Array™ (DMA) support • Strip charts for coupling and thickness monitoring • Indication table recording and Excel® reporting |

Code Compliance and Repeatability

WeldSight™ software combined with the FOCUS PX phased array instrument, weld series or custom probes, wedges, and accessories can help ensure code compliance for manufacturing and service inspections of welds with unique and complex characterizations.

Comply with fabrication standards:

| Applications targeted with this solution:

|

FocusPC软件

Get the most out of your FOCUS PX with FocusPC Software

Olympus offers a complete advanced phased array integration solution that meets the requirements of your most demanding inspections. The solution includes the FOCUS PX, a powerful and scalable acquisition unit; FocusPC, a powerful data acquisition and analysis software program; and three software development kits (SDK), FocusControl, FocusData, and OpenView SDK, to customize your software interface based on your application, and control FocusPC for a fully automated inspection solution.

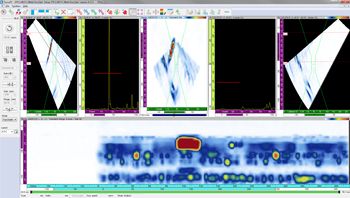

Convenient Interface

FocusPC is designed to give easy access to the most commonly used features, improving user experience and efficiency.

Toolbar

Quick access to the design, calibration, inspection and analysis features.

Optimized setup, acquisition, and analysis layoutsFreely subdivide and reorganize the different views.

| DashboardConvenient group and inspection sequence management.

|

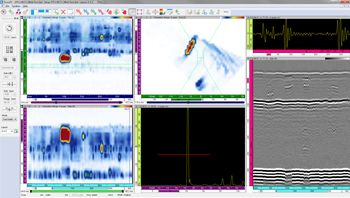

Powerful Tools

Design: |

Calibration: |

Inspection: |

Analysis: |

Powerful Acquisitions FeaturesFocusPC contains high-performance acquisition features that maximize the FOCUS PX performances and optimize inspection speed. FocusPC can drive up to four FOCUS PX units in parallel, enabling advanced multiprobe configurations and further reducing cycle time. Easy Connection The FOCUS PX seamlessly connects to any computer that has FocusPC installed, greatly simplifying the configuration process. Advanced Analysis ToolsAdvanced analysis tools are available in FocusPC so that you can get the most out of your FOCUS PX inspection data. Use the advanced data processing algorithms to extract valuable information and make the analysis process more efficient. |  |

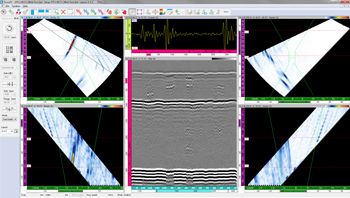

Fully Customizable Displays

FocusPC has fully customizable displays that can be adapted to better serve specific application requirements. Each view also has multiple customizable options, optimizing user experience and operator efficiency. Freely subdivide and reorganize the different views to create optimized setup, acquisition, and analysis layouts.

软件开发包

Software Development Kits (SDK)

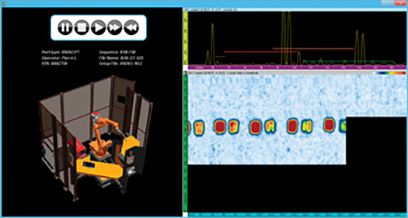

In addition to the FocusPC acquisition software, Olympus offers three software development kits (SDK), FocusControl, FocusData, and OpenView SDK, to customize your software interface based on your application and control FocusPC for a fully automated inspection solution.

| |

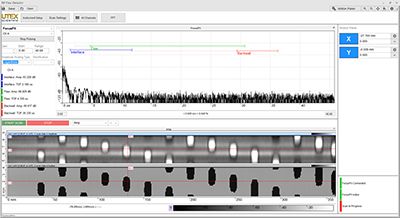

OpenView SDKFor applications that require specific features or a specific interface not offered by our standard software, the OpenView SDK enables you to create your own interface with the features required for your application. OpenView SDK is compatible with InspectionWare from UTEX and the HaroUT LabView library from Harotek. | Application-Dedicated User InterfaceBuild dedicated user interfaces based on the application requirements and make the inspection process more efficient. This provides better system workflow control and helps reduce the chance of operator-related mistakes. |

Photo Courtesy of DTEC GmbH Germany |  |

Inspection Process AutomationUse the FocusData and FocusControl SDKs to develop custom software to control the FOCUS PX and fully automate the inspection process, optimizing cycle time and improving overall system efficiency. | Custom Data AnalysisUse the SDKs to gain direct access to inspection data from custom software, enabling the development of application-dedicated data representations and customized analysis tools. |

应用

复合材料工件自动检测系统

技术规格

Specifications

|

|

Front | Back |

| Phased array channels |

16:64PR: 64

16:128PR/32:128PR: 128 |

|---|---|

| Number of pulsers |

16:64PR/16:128PR: 16 consecutive elements

32:128PR: 32 consecutive elements |

| Conventional UT channels |

4 dedicated UT channels

(8 connectors for pulse-echo and pitch-catch configurations support) |

| Data acquisition rate |

Up to 30 MB/s (1 FOCUS PX)

Up to 60 MB/s (2 to 4 FOCUS PX) |

| Acquisition speed | Up to 20000 12-bit A-scans/second of 750 points each |

| Amplitude resolution | 8-bit / 12-bit |

| Maximum number of A-scan samples | 16380 |

| Real-time data compression | 1 to 2000 ratio |

| Rectification | FW, HW+, HW–, and RF |

| Filtering | Digital band-pass, high-pass and low-pass filters |

| Voltage |

PA : 4 V, 9 V, 20 V, 40 V, 80 V, and 115 V

UT : 50 V, 100 V, and 190 V |

| Gain |

PA : 80 dB (46 dB analog + 34 dB digital)

UT : 120 dB (digital) |

| Pulse width |

PA : 30 ns to 500 ns (steps of 2.5 ns)

UT : 30 ns to 1000 ns (steps of 2.5 ns) |

| Bandwidth (-3 dB) |

PA : 0.6 MHz to 17.8 MHz

UT : 0.25 MHz to 28 MHz |

| Number of beams | Up to 1024 |

| Pulse repetition frequency (PRF) | 1 Hz to 20 kHz |

| Real-time averaging |

PA : 1, 2, 4, 8, 16

UT : 1, 2, 4, 8, 16, 32, 64 |

| Number of gates | 4 for detection; 1 for synchronization |

| Encoder | 2 axes (quadrature, clock direction) |

| Network interface | 1000BASE-T |

| Size (W x H x D)

With bumpers |

30.7 cm × 13.5 cm × 23.6 cm

(12 in. × 5.3 in. × 9.3 in.) |

| Size (W x H x D)

Without bumpers |

27.6 cm × 9.2 cm × 23.1 cm

(10.9 in. × 3.6 in. × 9.1 in.) |

| Weight

With bumpers | 4.8 kg (10.5 lb) |

| Weight

Without bumpers | 4.2 kg (9.2 lb) |

| IP rating | IP65 |