2.2 生成超声波(探头)

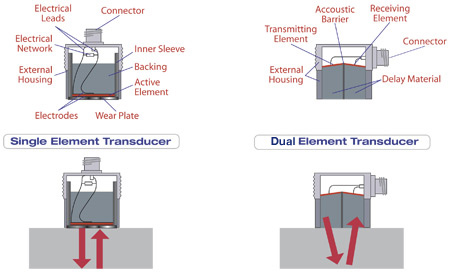

The ultrasonic waves used for flaw detection are generated and received by small probes called ultrasonic transducers, which convert electrical pulses into sound waves and sound waves into electrical energy. Transducers for flaw detection come in a wide variety of sizes, frequencies, and case styles, but most have a common internal structure.

Typically, the active element of the transducer is a thin disk, square, or rectangle of piezoelectric ceramic or piezocomposite that performs the conversion of electrical energy into mechanical energy (ultrasonic vibrations), and vice versa. When it is excited by an electrical pulse it generates sound waves, and when it is vibrated by returning echoes it generates a voltage. The active element, which is often referred to informally as the crystal, is protected from damage by a wearplate or acoustic lens, and backed by a block of damping material that quiets the transducer after the sound pulse has been generated. This ultrasonic subassembly is mounted in a case with appropriate electrical connections. All common contact, angle beam, delay line, and immersion transducers utilize this basic design. Dual element transducers, commonly used in corrosion survey applications, differ in that they have separate transmitting and receiving elements separated by a sound barrier, n o backing, and an integral delay line to steer and couple the sound energy, rather than a wearplate or lens.

Couplants

Ultrasonic couplants are used in virtually all contact testing applications to facilitate the transmission of sound energy between the transducer and the test piece. Couplants will typically be moderately viscous, nontoxic liquids, gels, or pastes. Their use is necessary because sound energy at the ultrasonic frequencies typically used for ultrasonic NDT not effectively transmitted through air. Even an extremely thin air gap between the transducer and the test piece will prevent efficient sound energy transmission and make conventional testing impossible.

A number of common substances such as water, motor oil, grease, and even some commercial products like hair gel can be used as ultrasonic couplants in many applications. Specialized couplants are used for high temperature testing and cases where special chemistry such as low halogen content is required.