超声检测的一般介绍

Many people are familiar with the medical applications of ultrasonic imaging, in which high-frequency sound waves are used to create highly detailed cross-sectional pictures of internal organs. Medical sonograms are commonly made with specialized multielement transducers known as phased arrays and their accompanying hardware and software. However, the applications of ultrasonic phased array technology are not limited to medical diagnosis. Phased array systems are also used in industrial settings to provide new levels of information and visualization in common nondestructive ultrasonic tests that include weld inspection, bond testing, thickness profiling, and in-service crack detection. Continue reading to learn the difference between phased array NDT inspections and traditional ultrasonic testing.

1. What Is Phased Array Ultrasound?

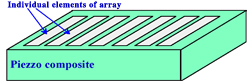

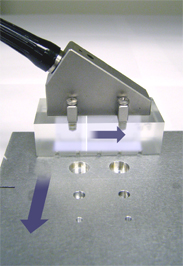

Conventional ultrasonic transducers for NDT commonly consist of either a single active element that both generates and receives high-frequency sound waves, or two paired elements—one for transmitting and one for receiving. Phased array probes, on the other hand, typically consist of a transducer assembly that contains anywhere from 16 to as many as 256 small individual elements that can each be pulsed separately. These may be arranged in a strip (linear array), ring (annular array), circular matrix (circular array), or more complex shape.

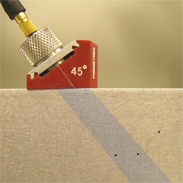

As is the case with conventional transducers, phased array probes may be designed for direct contact use, as part of an angle beam assembly with a wedge, or for immersion use with sound coupling through a water path. Transducer frequencies are commonly in the range of 2 MHz to 10 MHz. A phased array system will also include a sophisticated computer-based instrument that can drive the multielement probe, receive and digitize the returning echoes, and plot that echo information in various standard formats. Unlike conventional flaw detectors, phased array systems can sweep a sound beam through a range of refracted angles or along a linear path, or dynamically focus at many different depths. For these reasons, phased array systems can increase both flexibility and capability in inspection setups.

|

| Typical phased array probe assemblies |

|

| Typical multi-element construction |

2. How Do Phased Array Systems Work?

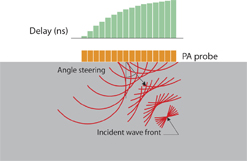

In the most basic sense, a phased array system uses the wave physics principle of phasing. It varies the time between a series of outgoing ultrasonic pulses in such a way that the individual wave fronts generated by each element in the array combine with each other to add or cancel energy in predictable ways that steer and shape the sound beam.

This is accomplished by pulsing the individual probe elements at slightly different times. Often the elements will be pulsed in groups of 4 to 32 to improve effective sensitivity by increasing aperture, which reduces unwanted beam spreading and enables sharper focusing. Software known as a focal law calculator establishes specific delay times for firing each group of elements to generate the desired beam shape, taking into account probe and wedge characteristics, as well as the geometry and acoustical properties of the test material. The programmed pulsing sequence selected by the instrument's operating software then launches a number of individual wave fronts in the test material. These wave fronts combine constructively and destructively into a single primary wave front that travels through the test material and reflects off cracks, discontinuities, back walls, and other material boundaries like any conventional ultrasonic wave. The beam can be dynamically steered through various angles, focal distances, and focal spot sizes in such a way that a single probe assembly can examine the test material across a range of different perspectives. This beam steering happens quickly so that a scan from multiple angles or with multiple focal depths can be performed in a fraction of a second.

The returning echoes are received by the various elements or groups of elements, time shifted as necessary to compensate for varying wedge delays, then summed. Unlike a conventional single element transducer, which will merge the effects of all beam components that strike its area, a phased array transducer can spatially sort the returning wavefront according to the arrival time and amplitude at each element. When processed by instrument software, each returned focal law represents the reflection from a particular angular component of the beam, a particular point along a linear path, and/or a reflection from a particular focal depth. The echo information can then be displayed in several different formats.

|

| Example of angled beam generated by flat probe by means of variable delay |

|

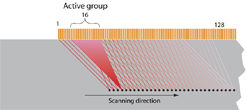

| Example of focused linear scan beam |

3. What Do The Images Look Like?

In most typical flaw detection and thickness gauging applications, the ultrasonic test data will be based on time and amplitude information derived from processed RF waveforms. These waveforms and the information extracted from them will commonly be presented in one or more of four formats: A-scans, B-scans, C-scans, or S-scans. This section shows some examples of image presentations from both conventional flaw detectors and phased array systems.

4. A-Scan Displays

An A-scan is a simple RF waveform presentation showing the time and amplitude of an ultrasonic signal, as commonly provided by conventional ultrasonic flaw detectors and waveform display thickness gauges. An A-scan waveform represents the reflections from one sound beam position in the test piece. The flaw detector A-scan below shows echoes from two side-drilled holes in a steel reference block. The columnar sound beam from a common single-element contact transducer intercepts two out of the three of the holes and generates two distinct reflections at different times that are proportional to the depth of the holes.

|  |

| Generalized beam profile | Straight beam A-scan image |

A single-element angle beam transducer used with a conventional flaw detector will generate a beam along one angular path. While beam spreading effects will cause the beam diameter to increase with distance, the area of coverage or field of vision of a conventional angle beam will still basically be limited to one angular path. In the example below, a 45 degree wedge at one fixed position is able to detect two of the side-drilled holes in the test block because they fall within its beam, but it is not possible to detect the third without moving the transducer forward.

|  |

Generalized beam profile

| Angle beam A-scan image |

A phased array system will display similar A-scan waveforms for reference, however in most cases they will be supplemented by B-scans, C-scans, or S-scans as seen below. These standard imaging formats aid the operator in visualizing the type and position of flaws in a test piece.

5. B-Scan Displays

A B-scan is an image showing a cross-sectional profile through one vertical slice of the test piece, showing the depth of reflectors with respect to their linear position. B-scan imaging requires that the sound beam be scanned along the selected axis of the test piece, either mechanically or electronically, while storing relevant data. In the case below, the B-scan shows two deep reflectors and one shallower reflector, corresponding to the positions of the side drilled holes in the test block. With a conventional flaw detector, the transducer must be moved laterally across the test piece.

|  |

| Generalized beam profile | Typical b-scan image showing relative hole depth |

A phased array system, on the other hand, can use electronic scanning along the length of a linear array probe to similarly create a cross-sectional profile without moving the transducer:

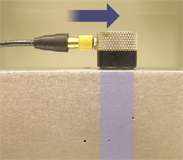

|

| Electronic linear scan (B-scan) image showing relative hole position and depth across the length of a linear array |

6. C-Scan Displays

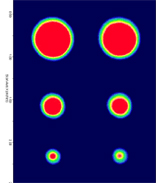

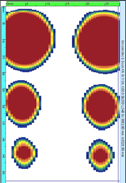

A C-scan is a two dimensional presentation of data displayed as a top or planar view of a test piece, similar in its graphic perspective to an x-ray image, where color represents the gated signal amplitude at each point in the test piece mapped to its x-y position. With conventional instruments, the single-element transducer must be moved in an x-y raster scan pattern over the test piece. With phased array systems, the probe is typically moved physically along one axis while the beam electronically scans along the other. Encoders will normally be used whenever precise geometrical correspondence of the scan image to the part must be maintained, although unencoded manual scans can also provide useful information in many cases.

The images that follow show C-scans of a reference block made with a conventional immersion scanning system with a focused immersion transducer, and with a portable phased array system using an encoded hand scanner and a linear array. While the graphic resolution is not fully equivalent, there are other considerations. The phased array system is field portable, which the conventional system is not, and costs about one-third the price. Additionally, the phased array image was made in a few seconds, while the conventional immersion scan took several minutes.

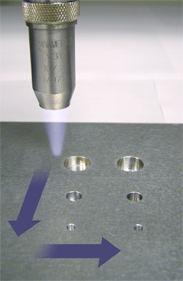

|  |

| Generalized beam profile and direction of motion | Conventional C-scan image showing hole position |

|  |

| Generalized beam profile and direction of motion | Phased array C-scan image showing hole position |

7. S-Scan Displays

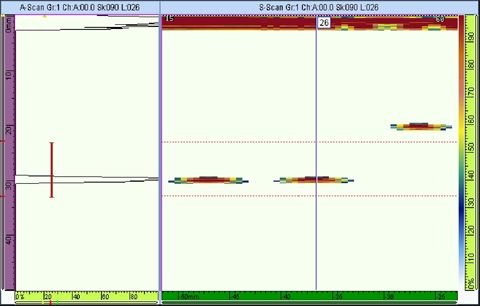

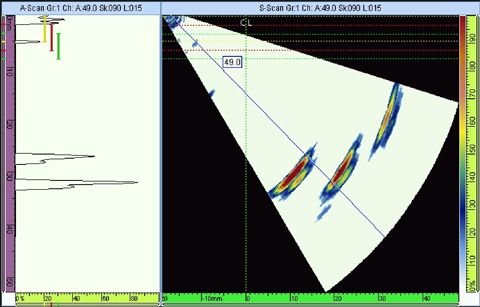

An S-scan or sectorial scan image represents a two-dimensional cross-sectional view derived from a series of A-scans that have been plotted with respect to time delay and refracted angle. The horizontal axis corresponds to test piece width, and the vertical axis to depth. This is the most common format for medical sonograms as well as for industrial phased array images. The sound beam sweeps through a series of angles to generate an approximately cone-shaped cross-sectional image. It should be noted that in this example, by sweeping the beam the phased array probe is able to map all three holes from a single transducer position.

|

| A-scan of a single angular component at left, composite sectorial scan at right. The cursor marking 49 degrees identifies the angular location of the displayed A-scan. |

Where Are Phased Array Systems Used?

Ultrasonic phased array systems can potentially be employed in almost any test where conventional ultrasonic flaw detectors have traditionally been used. Weld inspection and crack detection are the most important applications, and these tests are done across a wide range of industries including aerospace, power generation, petrochemical, metal billet and tubular goods suppliers, pipeline construction and maintenance, structural metals, and general manufacturing. Phased arrays can also be effectively used to profile remaining wall thickness in corrosion survey applications.

The benefits of phased array technology over conventional UT come from its ability to use multiple elements to steer, focus, and scan beams with a single transducer assembly. Beam steering, commonly referred to sectorial scanning, can be used for mapping components at appropriate angles. This can greatly simplify the inspection of components with complex geometries. The small footprint of the transducer and the ability to sweep the beam without moving the probe also aids inspection of such components in situations where there is limited access for mechanical scanning. Sectorial scanning is also typically used for weld inspection. The ability to test welds with multiple angles from a single probe greatly increases the probability of detection of anomalies. Electronic focusing permits optimizing the beam shape and size at the expected defect location, thus further optimizing probability of detection. The ability to focus at multiple depths also improves the ability for sizing critical defects for volumetric inspections. Focusing can significantly improve signal-to-noise ratio in challenging applications, and electronic scanning across many groups of elements allows for C-scan images to be produced very rapidly.

Further information on phased array technology and instrumentation is available from Evident. Contact us for details.