Webinar - Advances in Ultrasonic and Phased Array Methods of Corrosion Detection and Assessment

Webinar: Advances in Ultrasonic and Phased Array Methods of Corrosion Detection and Assessment

This webinar provides a brief introduction and overview of ultrasonic methods to detect and measure corrosion in piping, welds, and other critical components. |

Thursday, September 24, 2015

Conventional and Advanced Solutions to Improve the Detection of Corrosion in Pipes, Welds, and Components.

Conventional and Advanced Solutions to Improve the Detection of Corrosion in Pipes, Welds, and Components.

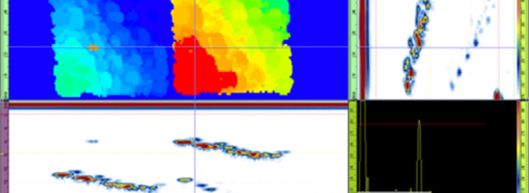

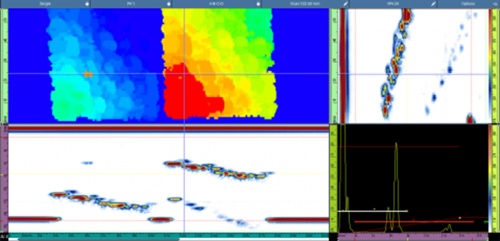

The proper detection and assessment of all types of corrosion damage mechanisms is a continued and growing concern across many industries. From conventional ultrasonic thickness gauges to more advanced phased array instrumentation, time-of-flight diffraction (TOFD) and guided wave solutions, nondestructive methods (NDT) are a viable way to properly detect, monitor, and measure corrosion levels.

This free webinar provides a brief introduction and overview of ultrasonic methods to detect and measure corrosion in piping, welds, and other critical components. It will provide guidelines for selecting the right ultrasonic inspection tools for the application and a look at the benefits and limitations of each. Inner and outer surface corrosion along with more exotic corrosion types like preferential weld root corrosion will be covered. Discussed will be new corrosion scanning and mapping solutions ranging from manual encoded to completely motorized using improved acquisition and analysis software. All levels of personnel involved in corrosion management and inspection programs are encouraged to attend.

Presenter:

Nicholas Bublitz has been employed by Olympus Scientific Solutions (Olympus NDT) for about 9 years, coming to work for them after obtaining an Associate in Applied Science Degree in Nondestructive Testing Technology from Southeast Community College. Having held positions ranging from Technical Support, Sales Management, Technical Support management, and Global Technical Support focusing on phased array, TOFD and automated system technology, he is now involved in many aspects of marketing, business development, product development and technical support across industries.