相位相干成像常见问题解答

问:相位相干性是什么意思?

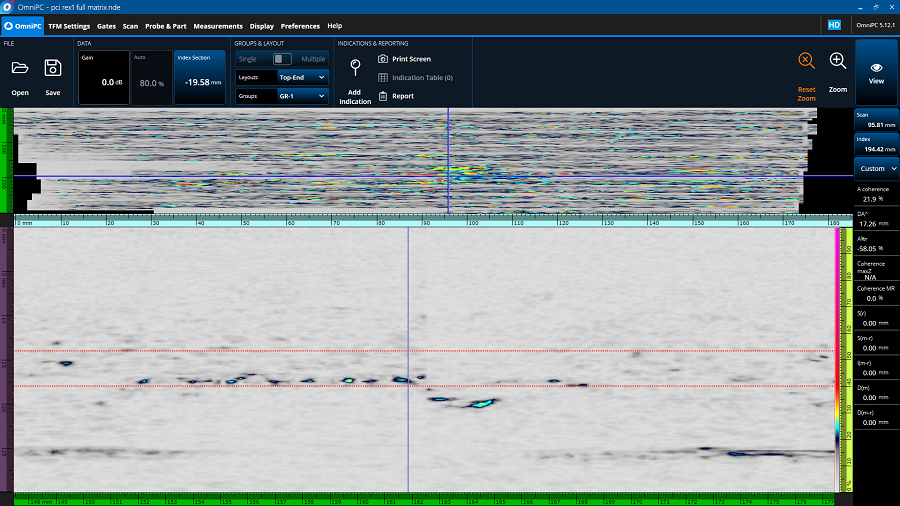

答:A扫描的相位是指在任何给定点构成信号的频率。由于建设性干扰和破坏性干扰的影响,A扫描可以由决定信号频率和振幅部分的相位部分来描述。相位相干成像(PCI) — 全聚焦法(TFM)成像的一种变化形式 — 通过比较A扫描之间的相位信息及其频率分布的相似程度,可以确定相位相干性。A扫描频率分布之间的相似性越大,相干性越高。

问:如何使用相位相干性来识别缺陷?

答:由于缺陷会反射或衍射超声波,因此这些缺陷返回信号的相位将集中在靠近探头频率的小频带内。相反,背景噪声的相位没有中心频率,并且覆盖宽频带。当多个A扫描在TFM区域相同位置的小频带内返回相同的中心频率时,则存在相干性。相干性越高,该位置存在缺陷的可信度越高。

问:PCI无振幅意味着什么?

答:对于PCI,在生成TFM图像时,根本不会考虑信号振幅。因此,即使在具有高衰减或背景噪声的材料中,仍然可以评估信号的相干性,因为即使在信号振幅较低的情况下,也可以找到频率分布。

问:生成PCI图像需要多长时间?

答:OmniScan X3 64探伤仪的相位相干成像采用的是实时模式,因此PCI图像将在检测过程中实时显示在屏幕上,其速度与传统TFM图像的生成速度大致相同。尽管PCI还有一个额外的处理步骤,但由于设备采用了功能强大、性能优异的数据处理器,该处理步骤所需的时间可以忽略不计。

问:PCI与其他基于相位的TFM成像技术有何不同?

答:OmniScan X3 64探伤仪的PCI技术(已集成到MXU 5.10更新中)能够在扫描期间进行实时数据处理,因此图像可以立即显示。当前面市的少数基于相位的成像设备必须采集和存储所有FMC数据,然后通过后处理提取相位信息。这导致扫描速度缓慢,仅适用于抽查。使用PCI时,强大的处理性能带来了扫描速度的提升,在实现实时高质量成像的同时,确保您完成整个检测。

问:为何使用PCI可以更容易地看到一些微小的缺陷和特征?

答:使用基于振幅的技术时,一些小缺陷在适当条件下仍然可见,但由于其返回的信号振幅较低,因此可能会在背景噪声中丢失或被另一个高振幅响应掩盖。尽管振幅较低,但从这些缺陷反射的信号相位存在高度相干性。在PCI图像中,这种高度相干性产生了易于表征的热点,可以用作尺寸调整的参考点。这些热点还可用于确定裂纹是否延伸到工件表面,在使用传统TFM时,有时可能无法看到裂纹。

问:为什么使用PCI时无需进行增益调整?

答:增益对结果没有影响,因为PCI的结果与振幅无关。

问:使用PCI时,如何根据参考调整信号?

答:您不需要调整!这是PCI的主要优点之一;由于无需根据参考反射器调整增益,因此可以更快创建设置。

问:如何确定PCI使用哪种TFM波集?

答:OmniScan X3 64扫描计划中的声学影响图(AIM)工具仍可用于选择波集。使用PCI时,振幅的变化不太重要,但确保TFM区域中有足够的声音分布仍然很重要。

问:什么类型的探头可以为PCI提供更好的性能?

答:拥有更多元件和更高频率的较大探头通常表现更好。由于PCI基于采集的基本A扫描之间的统计比较,可用的原始数据越多,相干缺陷和非相干(高方差)背景噪声之间的对比度越大。使用小型探头时,背景噪声中相干性的概率更大。同样的原因也适用于较低的探头频率,较高的频率可以提高对较小缺陷的敏感性。

问:稀疏触发模式可以用于PCI吗?

答:是的!与传统TFM一样,选择稀疏设置是为了实现图像质量和扫描速度之间的平衡。为了获得最佳图像质量,建议使用全矩阵设置,因为可为统计分析提供更多数据,但稀疏设置可以用于提高扫描速度。

问:为什么我们在使用PCI时要提高电压?

答:由于PCI中的信号不可能饱和,我们可以提高电压(例如,至160 Vpp)以充分利用仪器的脉冲功率,从而增加背景噪声并改善相干和非相干信号之间的对比度。与传统的基于振幅的超声技术逻辑相反,PCI的结果会随着噪声的增加而改善。

问:可以同时使用PCI和TFM吗?

答:PCI模式可同步应用于所有组,但可以在OmniScan X3 64探伤仪上进行模式切换,而无需进入扫描计划。

问:使用PCI时应如何确定缺陷大小?

答:使用PCI确定大小时,方法与使用TOFD时一样。不必识别相位反转并将光标放在信号峰上,只需简单识别端视图中缺陷末端的热点,并将光标放在最大值上即可。

更多信息,请参阅我们的“PCI入门”指南。