Loading...

概述

柔韧灵活的力量

管道弯头很容易受到损坏,例如流动加速腐蚀(FAC)造成的损坏,但由于弯头的形状会从凸面变为凹面,且管道的直径各有不同,因此对管道弯头的检测非常具有挑战性。FlexoFORM解决方案在扫查器中采用了柔性相控阵探头技术,有效地解决了这个难题。这种解决方案可从直径在4.5英寸到平面的弯头处采集到便于解读的数据,并发挥以下多种优势:

- 覆盖整个弯头区域

- 直观的二维C扫描成像

- 高分辨率数据(1毫米 × 1毫米)

- 对弯头的壁厚进行快速测量

- 水层系统可保持稳定的耦合效果

|  |

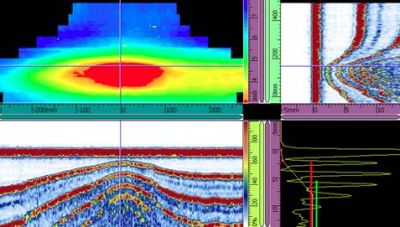

高分辨率数据

扫查器与OmniScan MX3或OmniScan

SX仪器配合使用,可以探测和测量不同类型的损伤或异常现象,如剩余壁厚、点蚀、管壁中的分层现象或夹杂物。高密度数据与探伤仪或OmniPC软件所提供的多种视图相结合,可呈现弯头状况的清晰图像,并使数据解读更迅速、更容易。

这种解决方案在扫查方向上进行编码,而且扫查器上直接装有一个步进按钮,可以在次轴方向上进行步进增量操作。

磁轮可以使扫查器稳固地贴附在管道上,而泡沫垫圈与表面永久接触,以使水层保持充水的状态。

|  |

扫查器使用水楔,可以在很大程度上降低水的消耗,并可轻松处理水中的气泡,同时还可使扫查器贴附在弯头的凸面和凹面上,与具有中等粗糙度的表面进行耦合,并使数据与表面回波同步。

每个水楔都呈曲面,以适用于特定直径的管道。只需将探头和楔块组装件安装到扫查器上,就可以使用这套系统进行检测了。

扫查选项

扫查选项

纵向扫查

在检测较小的管道或关注区域集中在管道周围的特定区域时,这种扫查配置非常有用。FlexoFORM的纵向扫查能力还使其成为检测发电厂锅炉水冷壁的一种强大工具。 |

|

手动扫查小直径弯头

我们还提供小直径楔块系列,用于检测直径小于4.5英寸的管道。使用这些楔块,用户可以手动扫查直径从1.3英寸到4英寸的弯头拱背(外拱线)区域或管道。要获得编码C扫描图像,可以将SFA1-SMALL楔块系列与Mini-Wheel(袖珍轮)编码器装配在一起进行扫查。 |

|

自动扫查

在某些应用中,纵向扫查比周向扫查更适合。在检测直径在8.625英寸以上,包括平面的管道时,可以使用SFA1-AUTO楔块系列。 |

|

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.

Sorry, this page is not available in your country