Connecting rod

Application

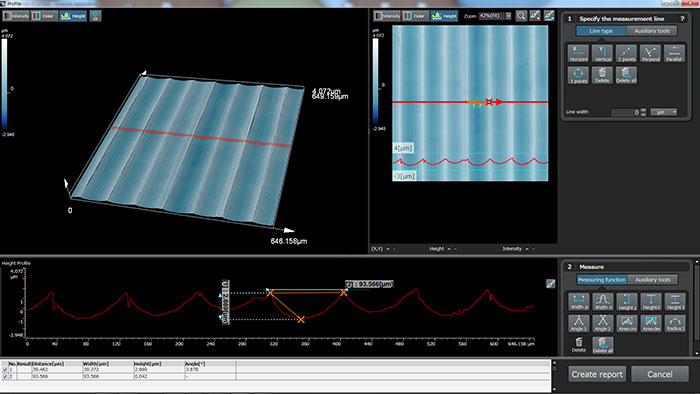

Connecting rods convert the up/down motion of pistons in engine cylinders into the rotational movement of crankshafts. The section of the connecting rod that slides against the crankshaft is referred to as the “big end,” the interior of which is lined with two thin shell components called con-rod bearings. These con-rod bearings are subjected to strong frictional force. For a connecting rod to slide smoothly against the crankshaft, the surface of the big end needs to be adequately lubricated. For this purpose, grooves are required on the inner surface of the big end to maintain a sufficient amount of lubricant. The oil grooves are configured according to precise technical specifications to ensure that the con rod slides as intended. Accordingly, the oil grooves need to be measured with high precision to ensure they meet the technical specifications. To enable microscopic observation of the interior surface of the big end, the connecting rod must be secured vertically in a custom fixture. However, when oriented this way on the observation stage of a microscope, the overall height of the con rod sample may obstruct the movement of the objective lens.

Olympus' solution

The Olympus LEXT OLS5000 3D measuring laser microscope is used to measure the oil grooves.

The OLS5000 microscope, when fitted with an optional extension frame, is capable of measuring samples up to 210 mm in height, enabling the observation of connecting rods mounted in a fixture.

Product characteristics

- The microscope’s extension frame enables observation/measurement of samples up to 210 mm in height.

- Measurement performance is enhanced to 4 times the speed of the previous LEXT model.

- Superior resolution (plane resolution: 0.12 µm) achieves high-precision measurement.

- Smart scan functionality for the acquisition of high-precision data helps eliminate data inconsistencies between operators.

Images

Connecting rod |

Segmented big-end portion |

Vertically oriented connecting rod mounted on a fixture |

Connecting rod mounted on the LEXT OLS5000 microscope stage

Oil groove laser microscopy imagery (20X objective lens, 1x zoom)

Measurement of the oil groove configuration