Background

In food manufacturing environments, maintaining product safety is essential. Processing equipment—such as mixers, grinders, and packaging lines—is typically made from stainless steel or other metal alloys that undergo friction, abrasion, and corrosion during routine operation. Over time, these conditions can generate metal wear, releasing small fragments or wear debris that may contaminate food products. Detecting and characterizing this debris supports contamination prevention, equipment-condition monitoring, and compliance with food safety regulations.

Problem

Conventional approaches for identifying wear debris in food, including magnet tests or visual inspections, are often insufficient for determining the source and elemental composition of the particles. Laboratory-based methods such as inductively coupled plasma–optical emission spectroscopy (ICP-OES) and atomic absorption spectrometry (AAS) offer high analytical accuracy but require long extensive sample preparation and destructive testing. These factors make them less practical for rapid or routine checks in production environments.

X-ray fluorescence (XRF) spectroscopy offers a practical alternative. Because XRF is a non-destructive, rapid elemental analysis technique, it can determine the composition and alloy grade of metal debris with minimal sample preparation. XRF can identify and quantify metals such as iron, nickel, aluminum, and zinc, which are common constituents of stainless steel and other machine components.

How XRF Can Help

In food manufacturing settings, XRF can support:

- Identification of the origin of wear debris by matching its elemental composition to specific equipment components (e.g., stainless steel grades 304 and 316).

- Root-cause analysis of contamination incidents.

- Monitoring of wear trends to support predictive maintenance before significant equipment damage or contamination occurs.

Given these advantages, XRF provides a fast, accurate, and non-destructive approach for metal-debris analysis that enhances product safety, equipment reliability, and contamination control.

The Evident Vanta™ handheld XRF analyzer provides a fast and effective solution for non-destructive verification of metal wear. The analyzer delivers alloy-composition chemistry and grade identification within seconds for materials including:

- Stainless steel

- Carbon steel

- Aluminum

- Titanium

- Nickel

- Cobalt

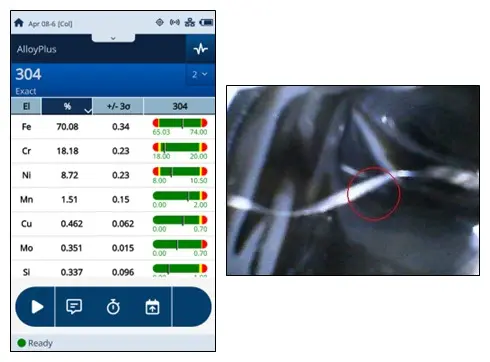

Figure 1. XRF results for grade 304 stainless steel and the corresponding aiming-camera image of the sample.

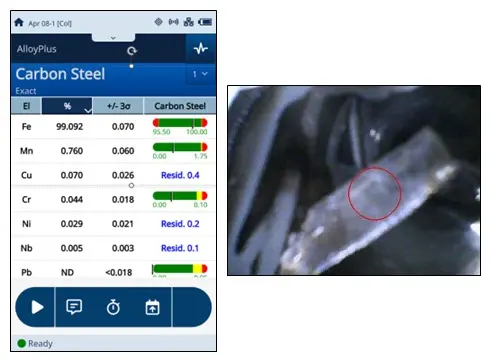

Figure 2. XRF results for carbon steel and the corresponding aiming-camera image of the sample.

Limitations

One limitation relates to spot size. The smallest collimator spot size available for the Vanta handheld XRF analyzer is 3 millimeters (0.12 inches). If the metal wear particle is smaller than the beam spot, the XRF signal may be diluted by the surrounding surface, which can cause the measured concentration to fall below the instrument’s detection limits.

In addition, the Vanta handheld XRF analyzer has a shallow penetration depth. Metal wear contaminated with food residue or oils may yield inconsistent XRF results, making it difficult to determine the alloy grade with accuracy. Proper cleaning and sample handling are therefore important to obtain reliable measurements.

Conclusion

The Evident Vanta handheld XRF analyzer provides a reliable, rapid, and non-destructive method for identifying and verifying metal wear in food manufacturing environments. Optional accessories, such as the Vanta workstation, may be required when analyzing small or irregular samples. The analyzer’s ability to deliver precise alloy-composition and grade identification within seconds makes it suitable for routine inspections, contamination investigations, and preventive-maintenance programs.

Although certain limitations exist, they are common to handheld XRF technology and can be mitigated through appropriate sample preparation and measurement practices. Overall, the Evident Vanta handheld XRF analyzer offers an effective on-site metal-verification tool that supports food safety, equipment reliability, and efficient root-cause analysis of metal-contamination events.

Related Content

Narrowing the List of Suspects—Linking Metal Contamination in Food to the Production Line

Detecting Lead in Soil—XRF Reveals Long-Lasting Soil Contamination from Paint and Gasoline

Unveiling the Power of pXRF: A Game-Changer for Haiti's Agriculture

.jpg?rev=5995)