Overview

|

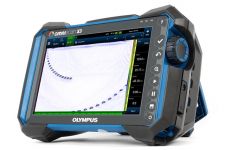

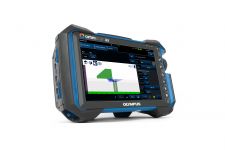

The OmniScan X4 flaw detector excels at a broad range of weld inspection applications, including:

|

|---|

Combine Techniques for Full Weld Coverage and Improved EfficiencyWhether you’re using automated, semiautomated, or manual scanning methods, the OmniScan X4 flaw detector supports many ultrasound techniques. In some cases, you can combine multiple techniques in the same scan to improve the probability of detection and make it easier to identify and size indications. |

|

|---|

Software Features

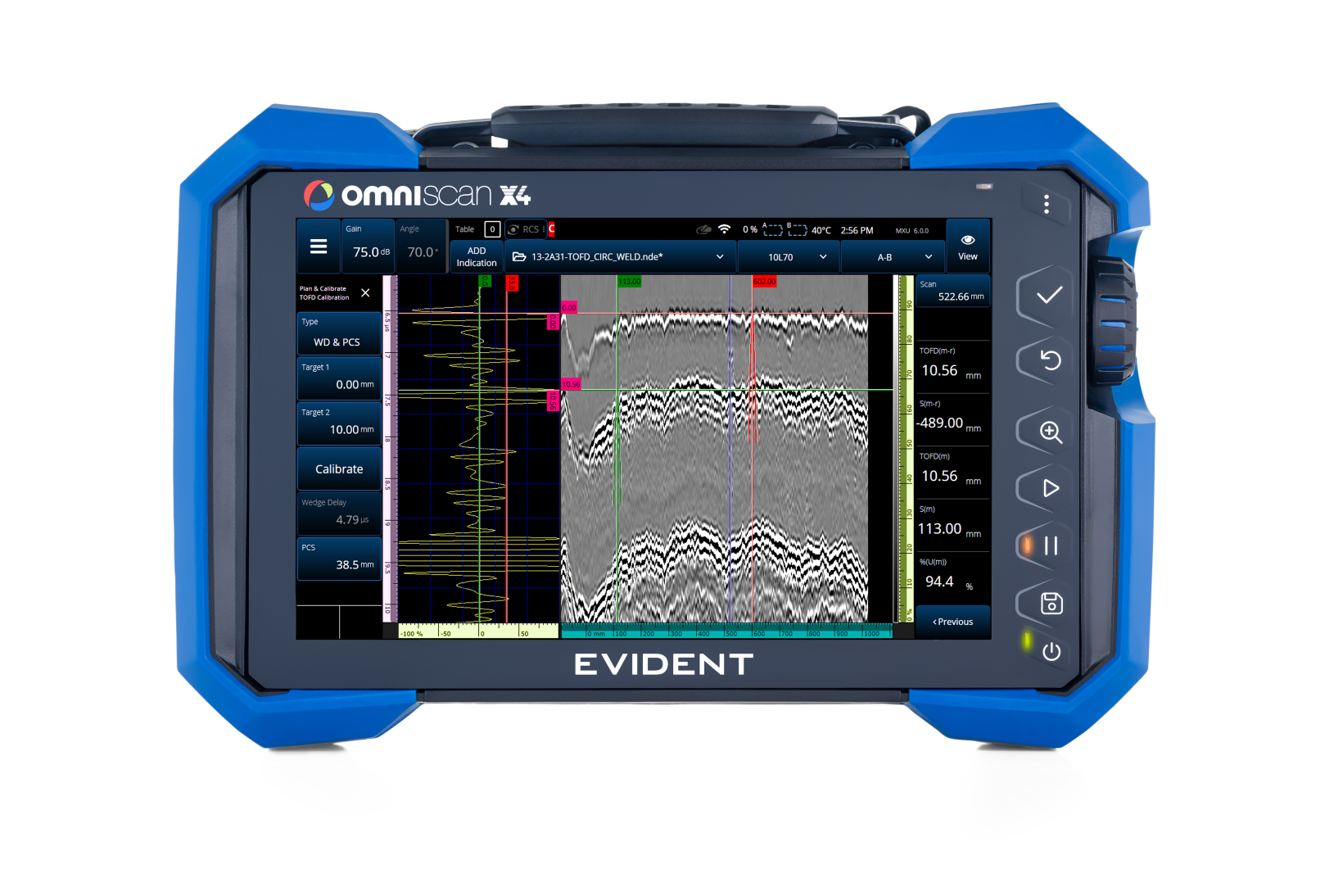

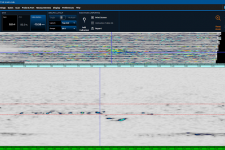

Dynamic Weld Inspection ToolsWe’ve added tools to improve the entire weld inspection process from creating your scan plan to analysis and reporting. |

Start Your Weld Inspection FasterCreate Setups Quickly The onboard scan plan tool is a fast, visual way to define your part, weld, and acoustic coverage in single or multiple group applications. Use it to confirm that your plan gives you full coverage and obtain a picture of the coverage area for your report. Fast, Single-Pass Calibration Get a clean calibration quickly when using an angle beam transducer. |  |

|---|

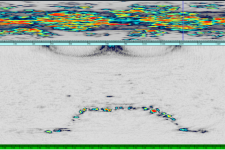

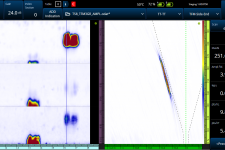

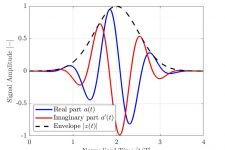

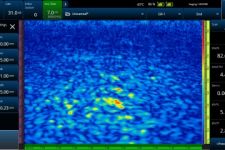

| More Efficient Weld InspectionsConfident Flaw Detection and Sizing through Twin TFM and PCI Twin phase coherence imaging (PCI) and totalfocusing method (TFM) images acquired through full matrix capture (FMC) make it easier to spot vertical defects in a weld. Acquiring up to four modes of propagation simultaneously on bothsides of the weld, you can view focused PCI and TFM images that are highly resolved throughout the volume of the weld as well as geometrically correct flaw representations for easier visualization. Fewer Rescans The extended 800% high amplitude range lets you characterize saturated indications, such as lack of fusion, without rescanning the component. Up to the Challenge of Austenitic Welds Onboard support of Dual Linear Array™ and Dual Matrix Array™ probes improves your data when inspecting austenitic welds. |

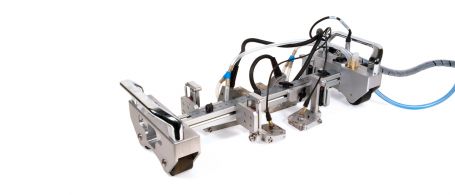

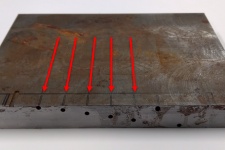

Solutions for Weld InspectionPair the OmniScan X4 flaw detector with a scanner for a complete weld inspection solution.

|  |

|---|

Scanners

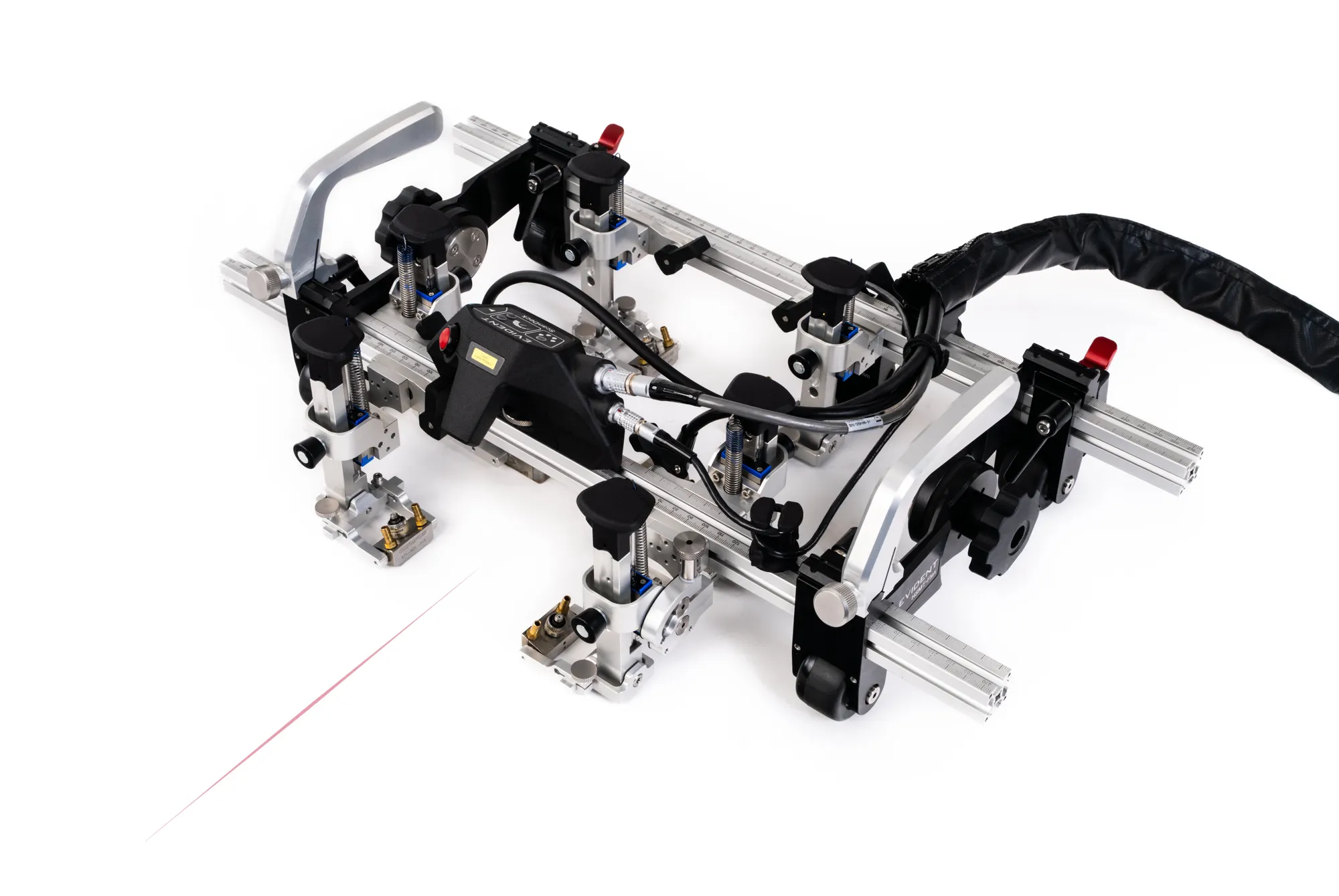

Wire EncoderAcquire high-quality phased array data with high positioning accuracy thanks to the wire encoder’s simple streamlined design, enabling you to focus on handling the probe. It installs quickly on both ferromagnetic and nonferromagnetic surfaces. AxSEAMThe semiautomated AxSEAM™ scanner eases long seam weld inspection in pipes. Monitor scan speed and couplant loss and start the data acquisition in the OmniScan™ unit on the ScanDeck™ Module. Easily adjustable probe holders support 4 probes, enabling PA, TOFD, and TFM, and PCI inspection. SteerROVER

The SteerROVER is a fully automated, steerable motorized scanner capable of performing weld inspection in remote locations. It can mount phased array as well as TOFD-P/E probes for inspection of circumferential or longitudinal welds.

WeldROVER™ Scanner

The WeldROVER scanner is designed to make fast, efficient phased array inspections on ferromagnetic piping or vessel girth welds and long seams with minimal training and setup time.

HST-Lite ScannerThe new HST-Lite scanner is the perfect choice for cost-effective, one-channel TOFD inspections when signal quality is important. The combination of magnetic wheels and spring-loaded probe holders offer the stability required to perform high quality, one-line inspections. The scanner can be operated using only one hand, and will attach to ferromagnetic surfaces even when in an upside-down position. Mini-Wheel Encoder

The Mini-Wheel Encoder is used for the positioning and dimensioning of defects in the scan axis. It can synchronize data acquisition with probe movement. It is also waterproof and compatible with Olympus standard PA wedges.

COBRA ScannerThe COBRA™ manual scanner combined with the OmniScan X4 flaw detector is used to perform circumferential welding inspections on small-diameter pipes. The COBRA small-diameter scanning unit can hold two PA probes to inspect pipes with ODs ranging from 0.84 to 4.5 in. HSMT-Compact ScannerThe HSMT-Compact is a manual one-axis encoded scanner. In particular, it is light and small, and also versatile. It can be used (with up to 4 probes) on plates and for circumferential scans on pipes as small as 4.5 in. OD pipes. HSMT-Flex Scanner

Designed with a central articulation joint, the HSMT-Flex™ scanner is intended for manual, encoded inspection of circumferential welds on pipes with outside diameters of 114.3 millimeters (4.5 inches) and larger, accommodating up to eight probes. The scanner is available in both standard and high-temperature models and can be equipped with a ScanDeck™ module. Its modular design allows for quick reconfiguration using only tool-free mechanisms.

ChainSCANNERThe ChainSCANNER™ solution facilitates manual inspection of pipes with outside diameters (OD) ranging from 76 mm to 965 mm (3 to 38 in.) Held by chain links instead of magnetic wheels, the scanner is well suited for weld or corrosion inspection on different types of materials using ultrasonic testing (UT), time-of-flight diffraction (TOFD), and phased array (PA) technologies. HST-X04

The HST-X04 time-of-flight diffraction (TOFD) manual scanner offers an efficient, low-cost, and versatile weld inspection solution.

VersaMOUSE ScannerThe VersaMOUSE™ is a scanner designed for linear encoded scans with a phased array probe. The integrated indexing button makes it ideal for 2-D mapping applications such as CFRP flat panel and corrosion inspections. The VersaMOUSE can perform an encoded one-line scan, followed by indexing of the position in the perpendicular direction. Another one-line scan can then be performed and juxtaposed to the previous scan. This process is repeated to produce a complete 2D map of the area of interest. |

Probes

RexoFORMWith its unique Rexolite delay line and small footprint, the RexoFORM wedge is optimized for phased array 0° and angle beam inspection in limited-access locations. It offers an economical corrosion mapping solution, conforming to a wide range of pipe diameters without the need for a continuous water supply. Weld Series ProbesWelding inspection probes offer housings combined with a front or top exit cable to avoid interference with the scanner probe holder. These probes are suitable for manual and automated inspections of welds. Our A31 and A32 weld series phased array probes and wedges simplify and standardize weld inspections, offering an improved signal-to-noise ratio. Passive-Axis Focusing (PAF) WedgesThis patented focusing wedge series helps compensate for beam divergence in the passive direction for pipe girth weld inspection. The smaller beam width enables the sizing of shorter flaws on the scan axis, helping lower rejection rates, and sharpening the images. Dual Array Probes for WeldOur Dual Linear Array (DLA) and Dual Matrix Array (DMA) probes consist of two linear or matrix array probes wired to the same connector with the capacity to perform transmit-receive longitudinal (TRL) inspection. They are particularly helpful when testing cladded pipes or highly attenuating materials, or for applications with high-sensitivity requirements. Dual Array Probe for Corrosion

This Dual Linear Array™ probe offers several advantages over conventional ultrasonic dual element transducers for corrosion survey applications. This phased array solution improves productivity through features such as larger beam coverage, faster scan speed, and C-scan imaging with increased data-point density.

Flexible Phased Array Probe

Our innovative flexible phased array probe enables users to undertake new applications. The FlexoFORM™ scanner uses a flexible array probe to perform corrosion inspection on pipe elbows.

Manual Contact ProbesOur A24 probe series for manual contact inspection incorporates an ergonomic case design, replaceable membrane, and large square aperture to work in a variety of applications. The 0.02-inch (0.5 mm) thick membrane makes it simpler to verify coupling, glides smoothly on rough surfaces, and is resistant to wear. EdgeFORMThe EdgeForm phased array solution enables automotive manufacturers to inspect for voids in bonded or glued seams in trunks, hoods, and door panels. Small-Footprint Probes

Small-footprint probes offer access to confined areas (A00 probe has an 8 × 8 mm footprint).

Universal Probes

Universal probes are designed to have a low-profile probe/wedge combination for easier access in restricted areas. A wide selection of wedges is available to suit any angle beam application. These probes are used for manual or automated inspection of 6.35 mm to 38 mm thick welds and the inspections of castings, forgings, pipes, tubes, and machined and structural components for cracks and welding defects.

Near-Wall Probes

Near-wall probes offer a shortened dead zone at both ends of the probe (1.5 mm between center of first or last element and housing edge). They are well suited for composite channel inspections and are used for C-scan inspections of composites (delamination, disbonding, and porosity).

Deep Penetration Probes

Deep penetration probes are specially designed to generate more powerful ultrasound signal. Thanks to a greater elevation, these probes can be used to perform non destructive testing on thicker carbon steel as well a noisy and granular materials.

Immersion ProbesImmersion probes are designed to be used with a water wedge or in an immersion tank when the test part is partially or wholly immersed. They are longitudinal wave probes that can be set up for refracted shear-wave inspections using a Rexolite wedge. Curved Array ProbesCurved array probes are made with a corrosion-resistant stainless steel case and are guaranteed waterproof up to 1 m underwater. The acoustic impedance of these probes matches water. They are compatible with adjustable immersion wedges and are used for the inspection of carbon fiber reinforced polymers (CFRP) corners and in addition to the inspection of composite for delamination. Immersion Corner Wedges for Curved Array Probes

Immersion corner wedges for curved array probes are available in specific radii and angles and also with adjustable radius to fit on various components to be inspected. These wedges are designed to perform manual scans and to accommodate the Mini-Wheel encoder.

Integrated Wedge and Code Compliant ProbesIntegrated wedge and code compliant probes combine the probe and the wedge in the same housing, offering the lowest-profile probe-and-wedge combination for contact angle beam inspection. Coupling is always good between probe and wedge interfaces, as there is no need for couplant between the probe and wedge. These probes are used for manual weld inspection using 40° to 70° simultaneously in addition to manual inspection of stress-corrosion cracking and AWS and DGS code compliant applications. Wedges for Angle Beam Probes

The wedges for angle beam probes are available in standard refracted angles of 0°, 45°, 55°, and 60° in steel for angle-beam inspections from 30° to 70°, SW or LW. They come with stainless steel screw receptacles providing a firm anchoring of probes to wedges. The IHC wedge option can be ordered to improve the quality of the inspection: irrigation, mounting holes for the wedge holder to work with any Evident scanner, and carbide pins to increase wear resistance.

|