Applications

The MX63 series is used in a range of reflected light microscopy applications. These applications are an example of some of the ways the system is used for industrial inspections.

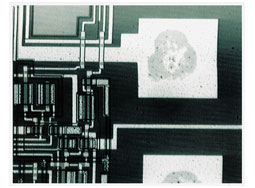

IR image of an electrode section

Infrared (IR) is used to look for defects inside IC chips and other devices made with silicon on glass.

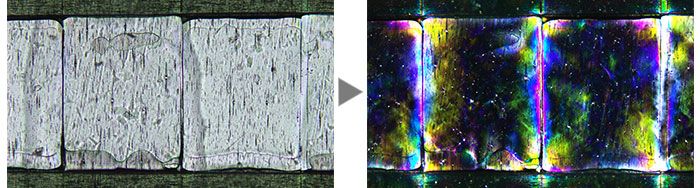

Film

(Left: Brightfield / Right: Polarized light)

Polarized light is used to reveal a material’s texture and the condition of crystals. It is suitable for inspections of wafer and LCD structures.

A hard disk

(Left: Brightfield / Right: DIC)

Differential interference contrast (DIC) is used to help view samples with minute height differences. It is ideal for inspections of samples having very minute height differences such as magnetic heads, hard-disk media, and polished wafers.

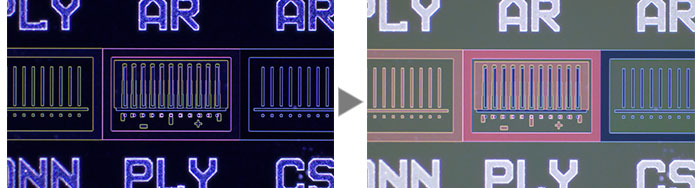

IC pattern on a semiconductor wafer

(Left: Darkfield / Right: MIX (Brightfield + Darkfield))

Darkfield is used for detecting minute scratches or flaws on a sample or inspecting samples with mirrored surfaces, such as wafers. MIX illumination enables users to view both patterns and colors.

Photoresist residue on a semiconductor wafer

(Left: Fluorescence / Right: MIX (Fluorescence + Darkfield))

Fluorescence is used for samples that emit light when illuminated with a specially designed filter cube. This is used to detect contamination and photoresist residue. MIX illumination enables the observation of both the photoresist residue and IC pattern.

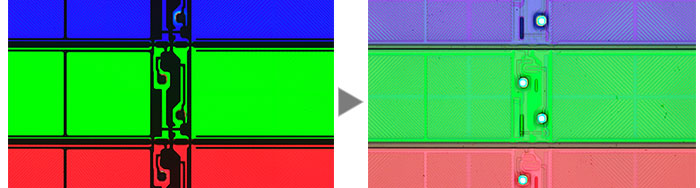

An LCD color filter

(Left: Transmitted Light / Right: MIX (Transmitted Light + Brightfield))

This observation technique is suitable for transparent samples such as LCDs, plastics, and glass materials. MIX illumination enables the observation of both the filter color and circuit pattern.