Overview

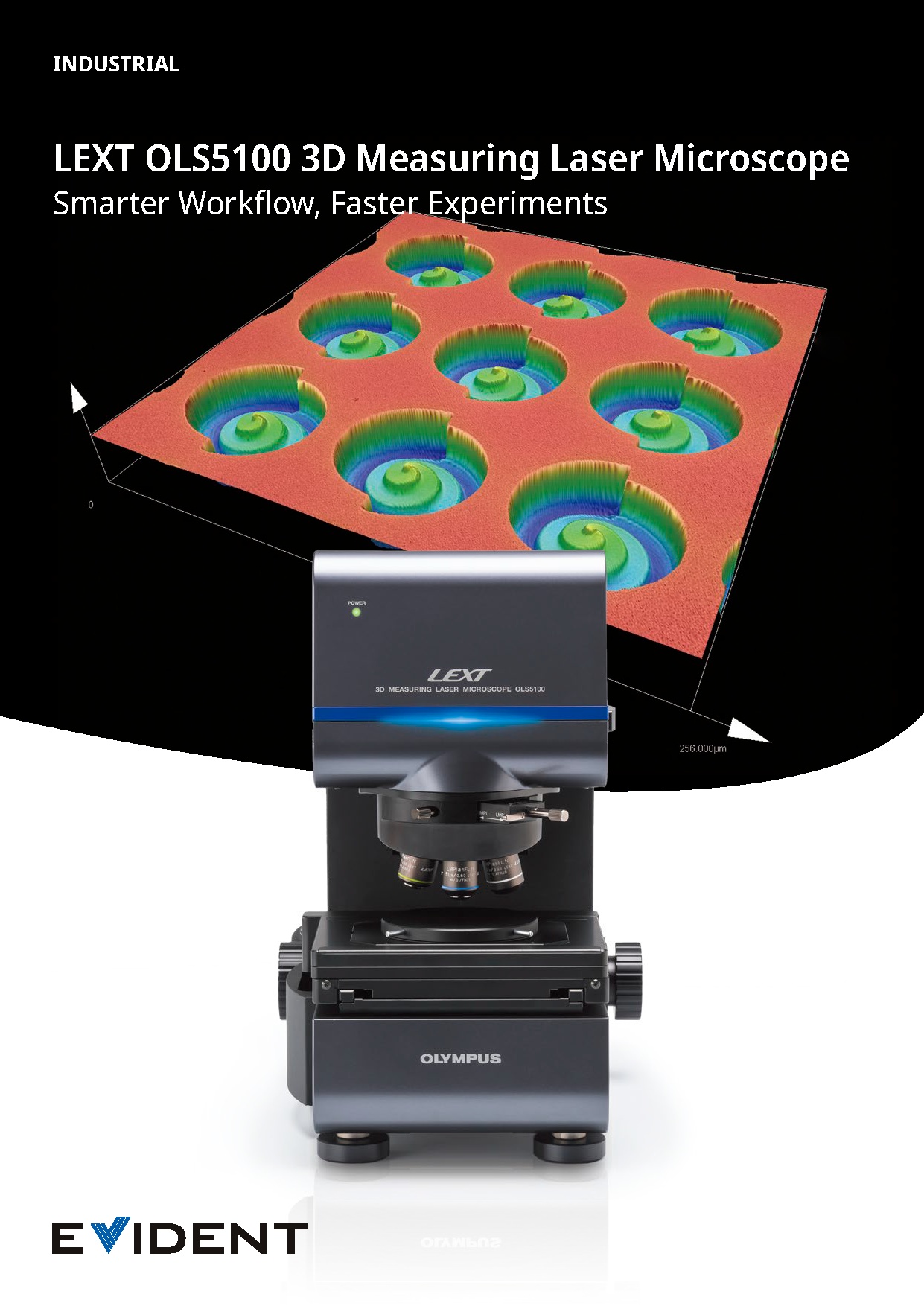

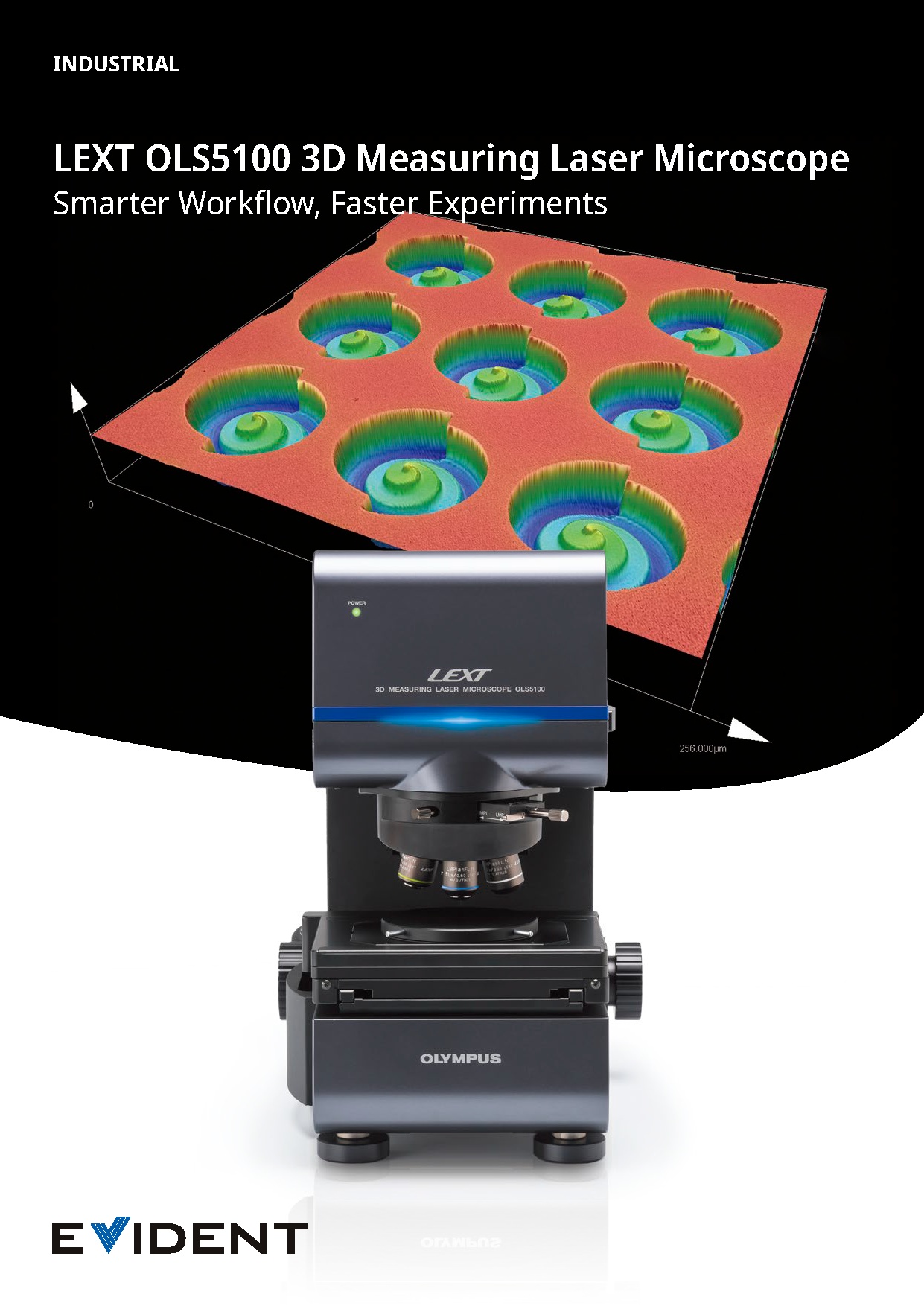

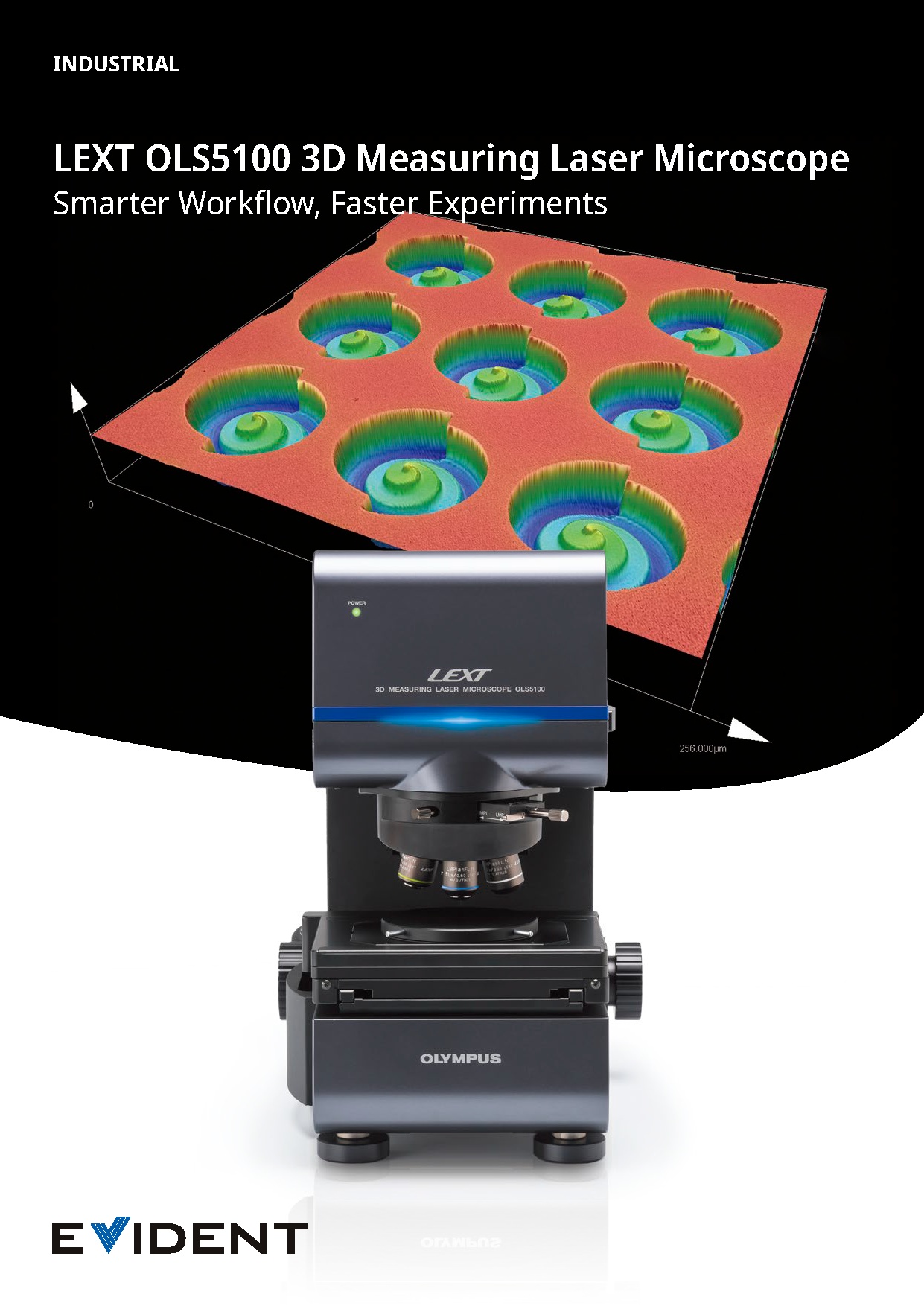

LEXT™ OLS5100 3D Laser Scanning MicroscopeLaser Microscope for Material AnalysisSmart Workflow, Faster ExperimentsBuilt for failure analysis and material engineering research, the OLS5100 laser microscope combines exceptional measurement accuracy and optical performance with smart tools that make the microscope easy to use. Precisely measure shape and surface roughness at the submicron level quickly and efficiently to simplify your workflow with data you can trust. Watch Video |  |

|---|

Easy Laser Scanning MicroscopyUsing the microscope is easy for novice and experienced users thanks to thoughtfully designed software.

The information, including guaranteed accuracy, on this web page is based on conditions set by Evident |

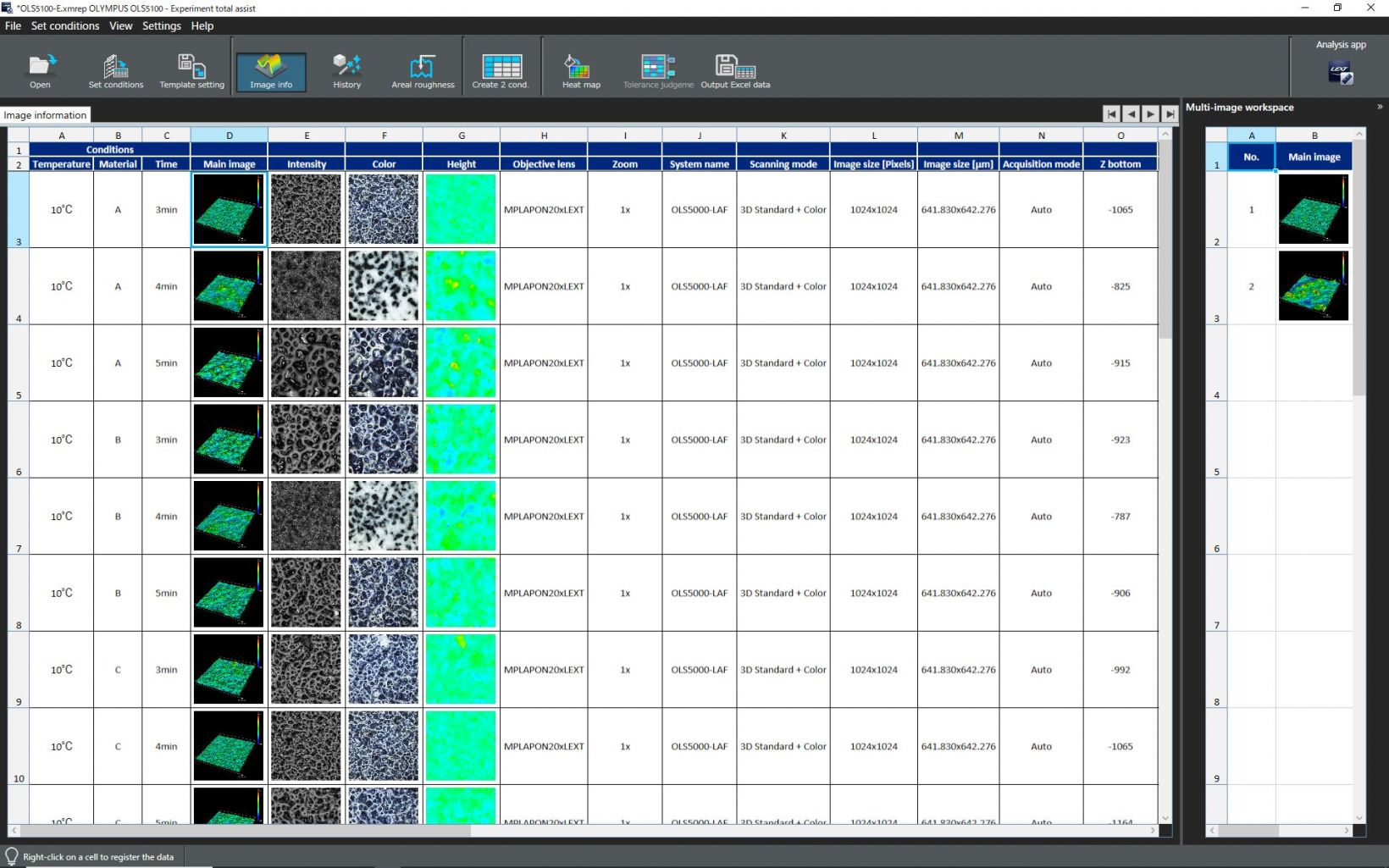

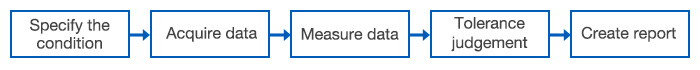

Easier Material Engineering and Failure Analysis ExperimentsThe Smart Experiment Manager makes your submicron 3D observation and failure analysis experiment workflows simpler by automating previously time-consuming tasks.

|

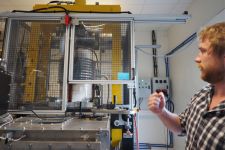

Fully Customizable to Your SpecificationsImplement all the advanced features of the OLS5100 laser scanning microscope for material analysis of large and heavy samples. |  |

|---|

Service and Support You Can TrustFrom calibration to training, we offer a broad portfolio of services to help you maintain optimal device performance. Evident service contracts are:

|

|

Benefits

Laser Microscope Benefits | ||

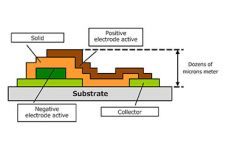

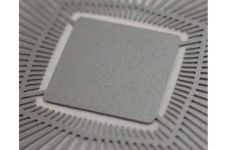

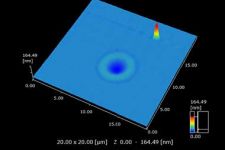

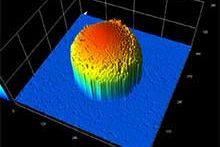

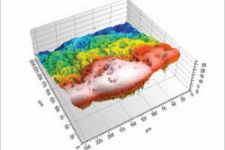

1. Sub-micron 3D observation/measurement  Observe steps in the nanometer range and measure height differences at the sub-micron level. | ||

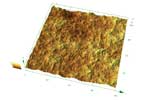

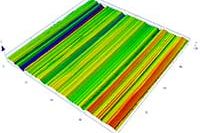

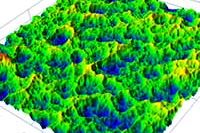

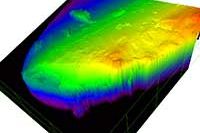

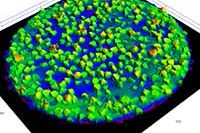

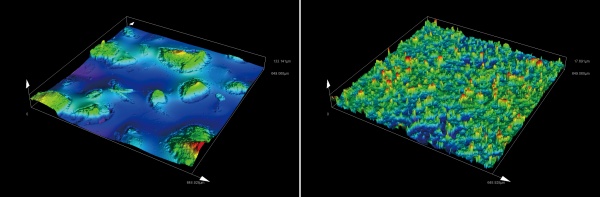

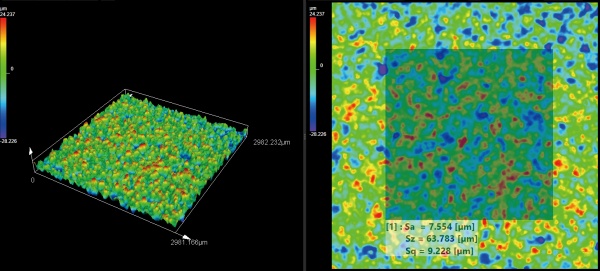

2. ISO25178-compliant surface roughness measurement  Measure surface roughness from linear to planar | ||

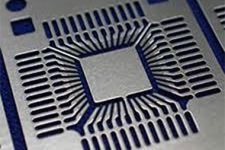

3. Non-contact, nondestructive, and fast  No sample preparation required—simply place the sample on the stage and you're ready to measure. | ||

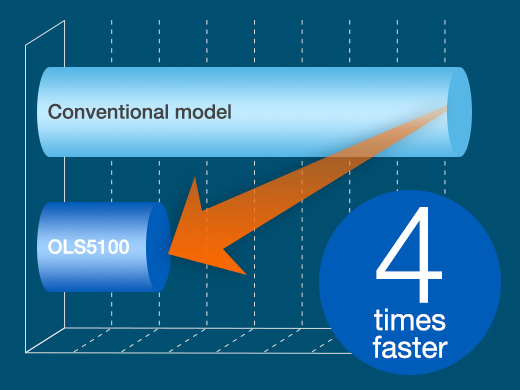

Reliable Data at the Push of a ButtonSmart Scan II Experienced and novice users alike can acquire data quickly and easily with the Smart Scan II feature. Place the sample on the stage, press the start button, and the microscope does the rest.

|  |

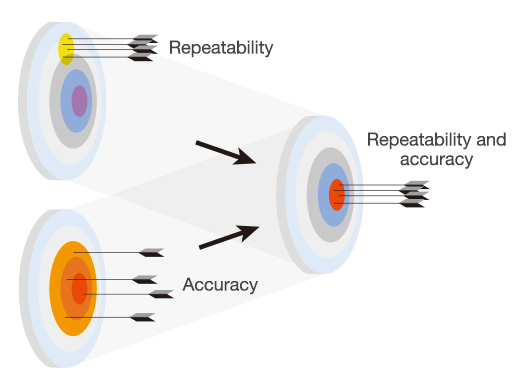

Measurement performance guarantee tailored to your operating environment | |

| Accuracy and repeatability guaranteed |

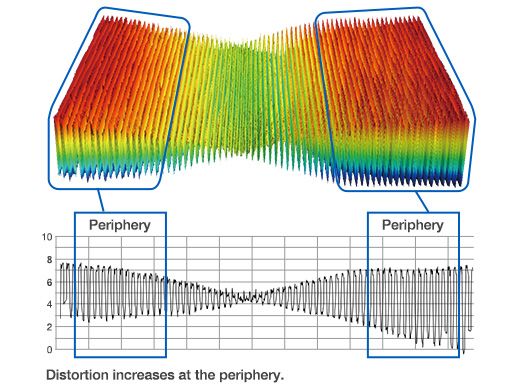

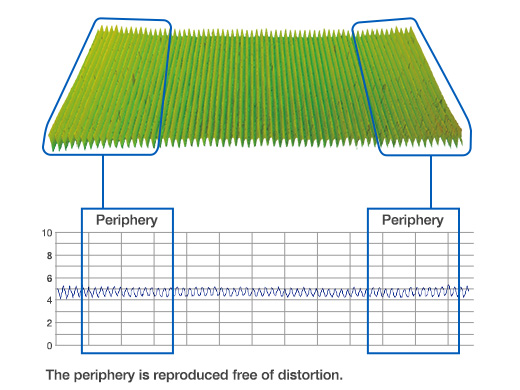

| Surface metrology beyond the field of view *Only for OLS5100-SAF/EAF |

User-Friendly High-Resolution/High-Magnification Observation | ||

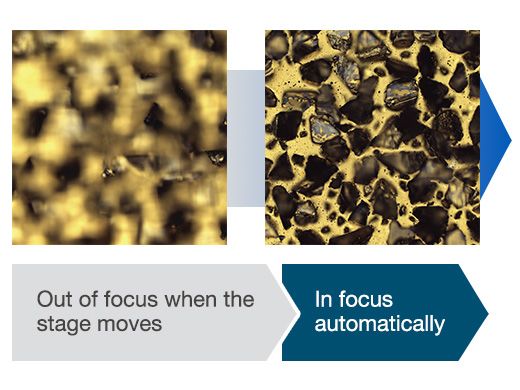

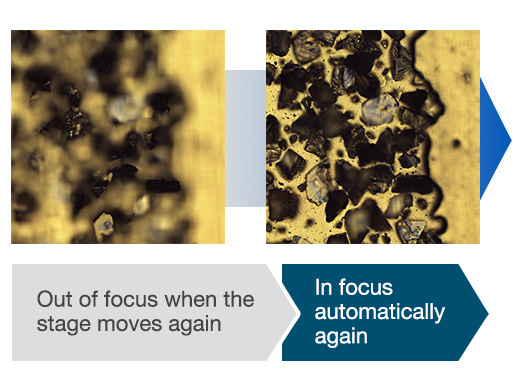

Continuous auto focus The microscope’s continuous autofocus keeps your images in focus when moving the stage or changing objectives, minimizing the need for manual adjustments. Permanent focus tracking enables you to perform observations quickly and easily. |  |  |

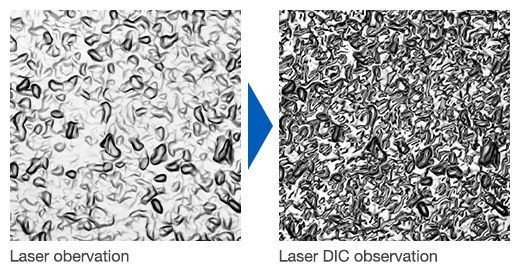

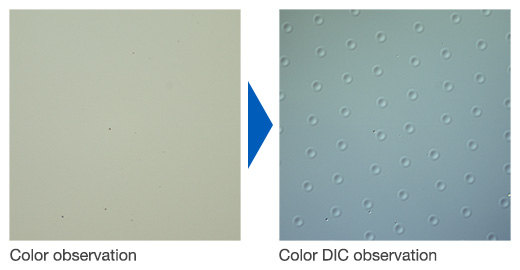

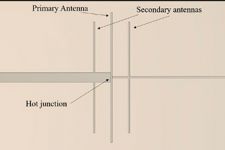

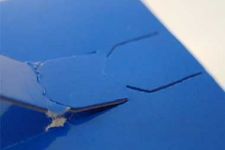

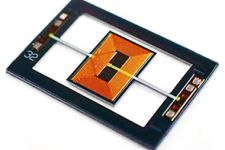

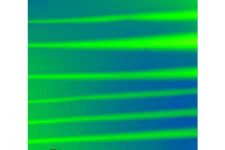

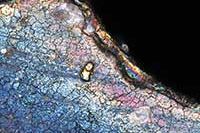

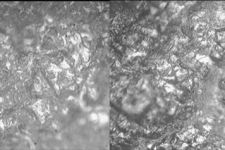

Dual DIC for nano-scale, real-time observation Detect minute damage in your sample with real-time, nanometerscale observation. Differential interference contrast (DIC) observation enables you to visualize nanometer-scale surface contours that are normally beyond the resolving power of a laser microscope. With DIC laser mode, the OLS5100 microscope can obtain live images comparable to those of an electron microscope, even when using a 5x or 10x low-power objective. |

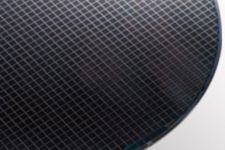

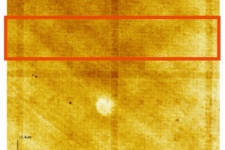

Back surface of wafer |

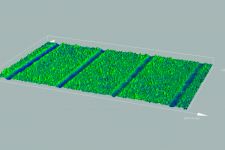

Hard disk landing zone |

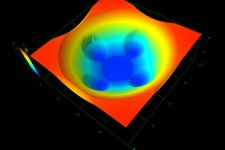

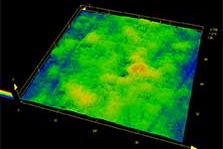

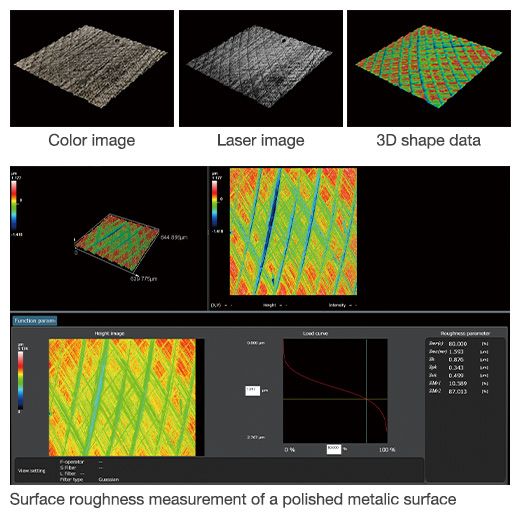

Comprehensive AnalysisMany analysis functions are available. The following is just an example, so please download the brochure or contact your Evident representative for details. | |

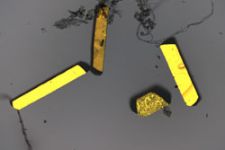

| ISO25178 compliant areal roughness measurement The OLS5100 microscope scans the sample surface with a 0.4 μm diameter laser beam, enabling it to easily measure the surface roughness of samples that cannot be measured with contact surface roughness gauges. The ability to simultaneously acquire the color image, laser image, and 3D shape data of a surface that can't be measured with a contact surface roughness gauge expands the scope of analysis. |

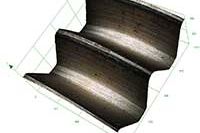

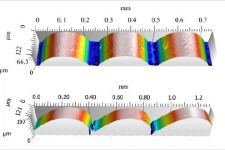

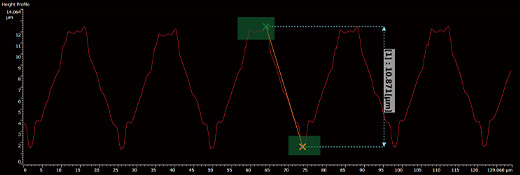

Measurement of the step between the highest and lowest points in a surface profile | Profile measurement/ Measurement assist tool The profile measurement function displays the surface profile by arbitrarily drawing a measurement line on the position to be measured on an image. It also measures the step between any two arbitrary points, width, cross-sectional area, and radius. Unlike contact-based measuring tools, setting the measured positions is easy. The measurement lines and points can be checked on the image, so even a very small site can be measured accurately. With the Measurement assist tool, the point to be measured can be correctly specified using the highest, lowest, middle, and/or mean points. When a site is specified in the acquired data, the feature points are automatically extracted according to specified conditions. |

|

Software

Simple Material Engineering and Failure Analysis Experiment Management | |

Managing experiment conditions when testing new materials is complicated, so the OLS5100 laser microscope’s Smart Experiment Manager simplifies the process by automating key steps, such as creating the experiment plan. |  |

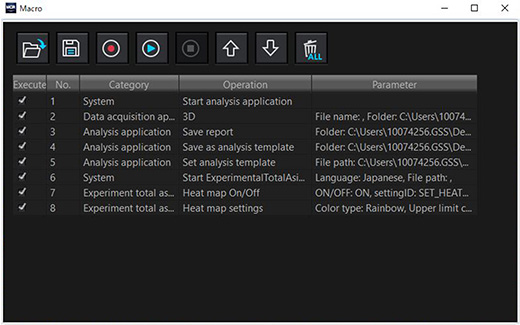

Automate Routine Workflows | |

| Macro function You can automate the entire inspection workflow using the macro production tool. Easily create and edit procedures, and then run the registered macro file to obtain reliable results. Combined with the Smart Experiment Manager, you can make pass/fail judgments with a single click. |

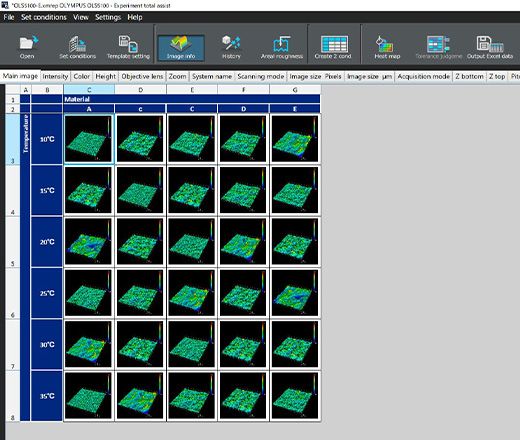

Streamline Data Organization | |

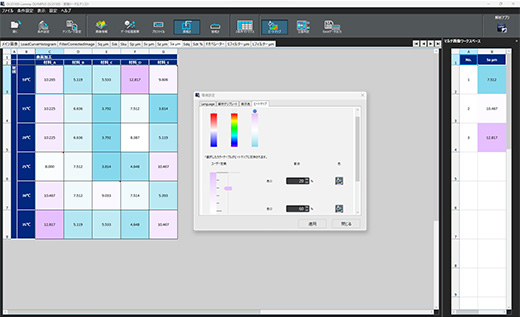

| Quick data sorting |

| Automatic data input |

Easy Experiment Condition Data Organization | |

Automatic file name generation You can click on each cell in the experiment plan, and the software will automatically generate a file name that contains the evaluation conditions for easy record keeping. Each file contains the associated images and data. |  |

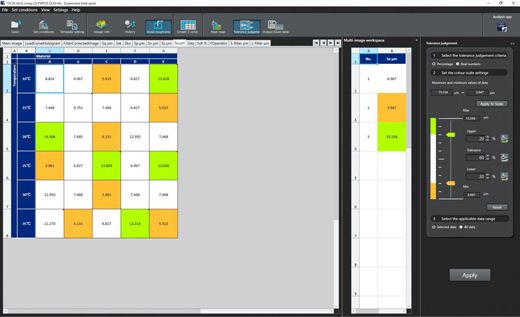

Fast Measurement Results | |

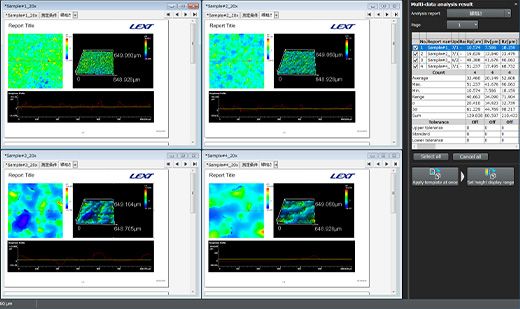

| Tolerance judgment |

| Heat map |

Multidata Analysis | |

| Comparative data analysis |

|

Specifications

Main unit

| Model | OLS5100-SAF | OLS5100-SMF | OLS5100-LAF | OLS5100-EAF | ||

|---|---|---|---|---|---|---|

| Total magnification | 54x–17,280x | |||||

| Field of view | 16 µm–5,120 µm | |||||

| Measurement principle | Optical system |

Reflection-type confocal laser scanning laser microscope

Reflection-type confocal laser scanning laser-DIC microscope Color Color-DIC | ||||

| Measurement principle | Light receiving element |

Laser: Photomultiplier (2 channels)

Color: CMOS color camera | ||||

| Height measurement | Display resolution | 0.5 nm | ||||

| Height measurement | Dynamic range | 16 bits | ||||

| Height measurement | Repeatability σn-1*1 *2 *5 | 5X: 0.45 μm, 10X: 0.1 μm, 20X: 0.03 μm, 50X : 0.012 μm, 100X : 0.012 μm | ||||

| Height measurement | Accuracy *1 *3 *5 | 0.15+L/100 μm (L:Measuring length[μm]) | ||||

| Height measurement | Accuracy for stitched image *1 *3 *5 | 10X: 5.0+L/100 μm, 20X or higher: 1.0+L/100 μm (L: Stitching length [μm]) | ||||

| Height measurement | Measurement noise (Sq noise) *1 *4 *5 | 1 nm (Type) | ||||

| Width measurement | Display resolution | 1 nm | ||||

| Width measurement | Repeatability 3σn-1 *1 *2 *5 | 5X: 0.4 μm, 10X: 0.2 μm, 20X: 0.05 μm, 50X: 0.04 μm, 100X: 0.02 μm | ||||

| Width measurement | Accuracy *1 *3 *5 | Measurement value +/- 1.5% | ||||

| Width measurement | Accuracy for stitched image *1 *3 *5 | 10X: 24+0.5L μm, 20X: 15+0.5L μm, 50X: 9+0.5L μm, 100X: 7+0.5L μm (L: Stitching length [mm]) | ||||

| Maximum number of measuring points in a single measurement | 4096 × 4096 pixels | |||||

| Maximum number of measuring points | 36-megapixels | |||||

| XY stage configuration | Length measurement module | • | NA | NA | • | |

| XY stage configuration | Operating range | 100 × 100 mm (3.9 × 3.9 in.) Motorized | 100 × 100 mm (3.9 × 3.9 in.) Manual | 300 × 300 mm (11.8 × 11.8 in.) Motorized | 100 × 100 mm (3.9 × 3.9 in.) Motorized | |

| Maximum sample height | 100 mm (3.9 × 3.9 in.) | 40 mm (1.6 in.) | 37 mm (1.5 in.) | 210 mm (8.3 in.) | ||

| Laser light source | Wavelength | 405 nm | ||||

| Laser light source | Maximum output | 0.95 mW | ||||

| Laser light source | Laser class | Class 2 (IEC60825-1:2007, IEC60825-1:2014)*6 | ||||

| Color light source | White LED | |||||

| Electrical power | 240 W | 240 W | 278 W | 240 W | ||

| Mass | Microscope body | Approx. 31 kg (68.3 lb) | Approx. 32 kg (70.5 lb) | Approx. 50 kg (110.2 lb) | Approx. 43 kg (94.8 lb) | |

| Mass | Control box | Approx. 12 kg (26.5 lb) | ||||

*1 Guaranteed when used in constant temperature and constant-humidity environment (temperature: 20˚C±1˚C, humidity: 50%±10%) specified in ISO554(1976), JIS Z-8703(1983).

*2 For 20x or higher, when measured with MPLAPON LEXT series objectives.

*3 When measured with dedicated LEXT objective.

*4 Typical value when measured with MPLAPON100XLEXT objective, and may differ from the guaranteed value.

*5 Guaranteed under Evident Certificate System.

*6 OLS5100 is a Class 2 laser product. Do not stare into beam.

** The OS license of Window 10 has been certified for the microscope controller provided by Evident. Therefore, Microsoft's license terms are applied and you agree to the terms.Please refer to the following for Microsoft license terms.

https://www.microsoft.com/en-us/Useterms/Retail/Windows/10/UseTerms_Retail_Windows_10_english.htm

Objectives

| Series | Model | Numerical Aperture (NA) | Working Distance (WD) (mm) |

|---|---|---|---|

| UIS2 objective lens | MPLFLN2.5X | 0.08 | 10.7 |

| MPLFLN5X | 0.15 | 20 | |

Dedicated LEXT objective lens (10X) | MPLFLN10XLEXT | 0.3 | 10.4 |

Dedicated LEXT objective lens (high-performance type) | MPLAPON20XLEXT | 0.6 | 1 |

| MPLAPON50XLEXT | 0.95 | 0.35 | |

| MPLAPON100XLEXT | 0.95 | 0.35 | |

Dedicated LEXT objective lens (long working distance type) | LMPLFLN20XLEXT | 0.45 | 6.5 |

| LMPLFLN50XLEXT | 0.6 | 5.2 | |

| LMPLFLN100XLEXT | 0.8 | 3.4 | |

| Super long working distance lens | SLMPLN20X | 0.25 | 25 |

| SLMPLN50X | 0.35 | 18 | |

| SLMPLN100X | 0.6 | 7.6 | |

| Long working distance for LCD lens | LCPLFLN20XLCD | 0.45 | 8.3-7.4 |

| LCPLFLN50XLCD | 0.7 | 3.0-2.2 | |

| LCPLFLN100XLCD | 0.85 | 1.2-0.9 |

Application software

| Standard software | OLS51-BSW | |||

|---|---|---|---|---|

| Standard software | Data acquisition app | Analysis app (simple analysis) | ||

| Motorized stage package application*1 | OLS50-S-MSP | |||

| Advanced analysis application*2 | OLS50-S-AA | |||

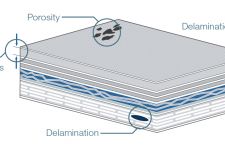

| Film thickness measurement application | OLS50-S-FT | |||

| Auto edge measurement application | OLS50-S-ED | |||

| Particle analysis application | OLS50-S-PA | |||

| Experimental total assist application | OLS51-S-ETA | |||

| Sphere/cylinder surface angle analysis application | OLS50-S-SA | |||

*1 Including auto-stitching data acquisition and multi-area data acquisition functions.

*2 Including Profile analysis, Difference analysis, Step-height analysis, Surface analysis, Area/volume analysis, Line roughness analysis, Area roughness analysis and Histogram analysis.

Evident Laser Microscopes

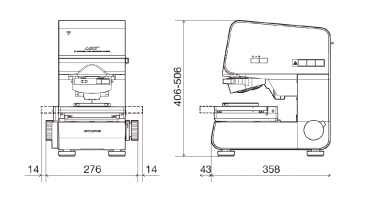

OLS5100-SAF Setup Example

OLS5100-SAF

|

| |

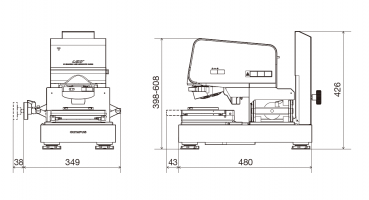

OLS5100-EAF

|

| |

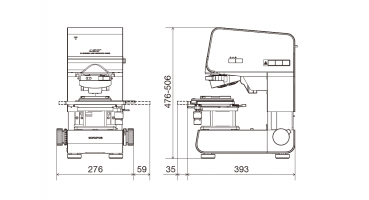

OLS5100-SMF

|

| |

OLS5100-LAF

|

|

Control unit