|

Software

|

CIX-ASW-V1.6

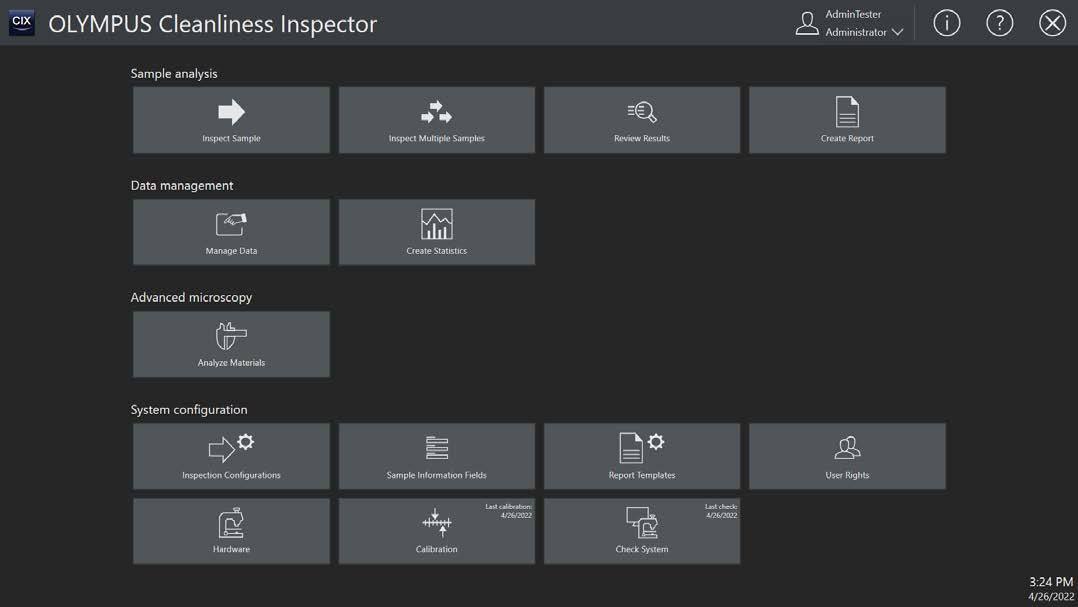

| - Dedicated workflow software for technical cleanliness inspection

|

|

Languages

|

GUI

| - GUI: English, French, German, Spanish, Japanese, Simplified Chinese, and Korean

|

|

Online help

| - Online help: English, French, German, Spanish, Japanese, Simplified Chinese, and Korean

|

|

License management

| - Software license activated by license card (already activated at installation)

|

|

User management

| - System can be connected to a network for domain administration

- The range of functions can be selected depending on the authenticated user.

|

|

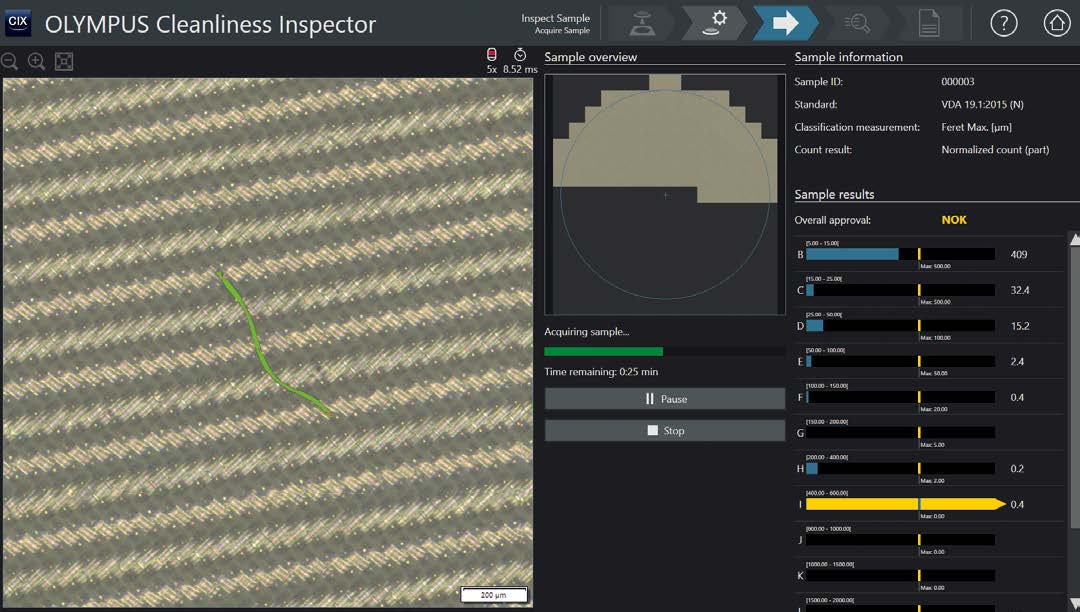

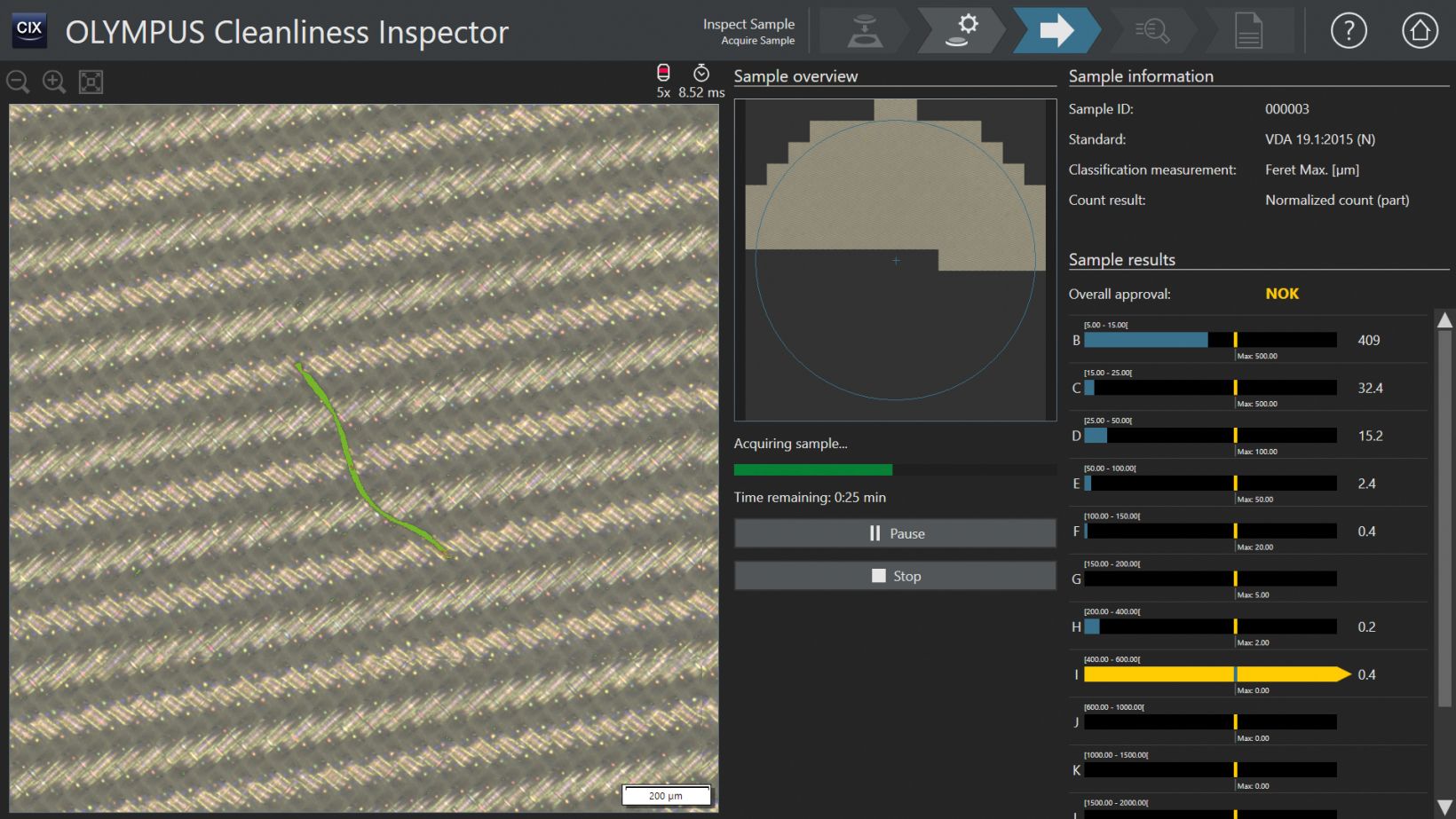

Live image

|

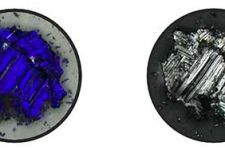

Display in color mode

| - Metal particles are shown as blue and nonmetallic particles in their natural color

|

|

Window fit method

| - The image is always displayed in a full view

|

|

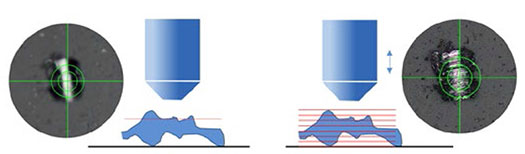

Live detection

| - Particles are detected as soon as they are captured for improved speed

- User can stop the process if the measurement result is not good

|

|

Live classification

| - Particles are classified as soon as they are detected

- Particle size classes are identified on the user interface during the live acquisition

|

|

Microscope mode

| - Microscope mode can be accessed for microscopic imaging

- Optional access to material analysis solutions (not included)

|

|

Image capture and manual measurements

|

Collecting user snapshots

| - In the review mode it is possible to acquire single images from any position on the sample, as well as acquire images in the live observation mode (from direct image) or the sample view mode (from recorded data)

- Images can be stored in .tif, .jpg, or .png files with a standard resolution of 1000 × 1000 pixels

- Snapshots can be linked to detected particle and used in the analytical report afterwards

- Particle snapshots can be automatically acquired in EFI (extended focus imaging) mode

- Recordings taken in EFI mode can be used in the analytical report

|

|

Manual measurements

| - It is possible to perform arbitrary distance measurements on an acquired snapshot

- Arbitrary measurements can be renamed, and the color can be colored

- Arbitrary measurements and a scale bar are saved in the image when stored

|

|

Hardware control

|

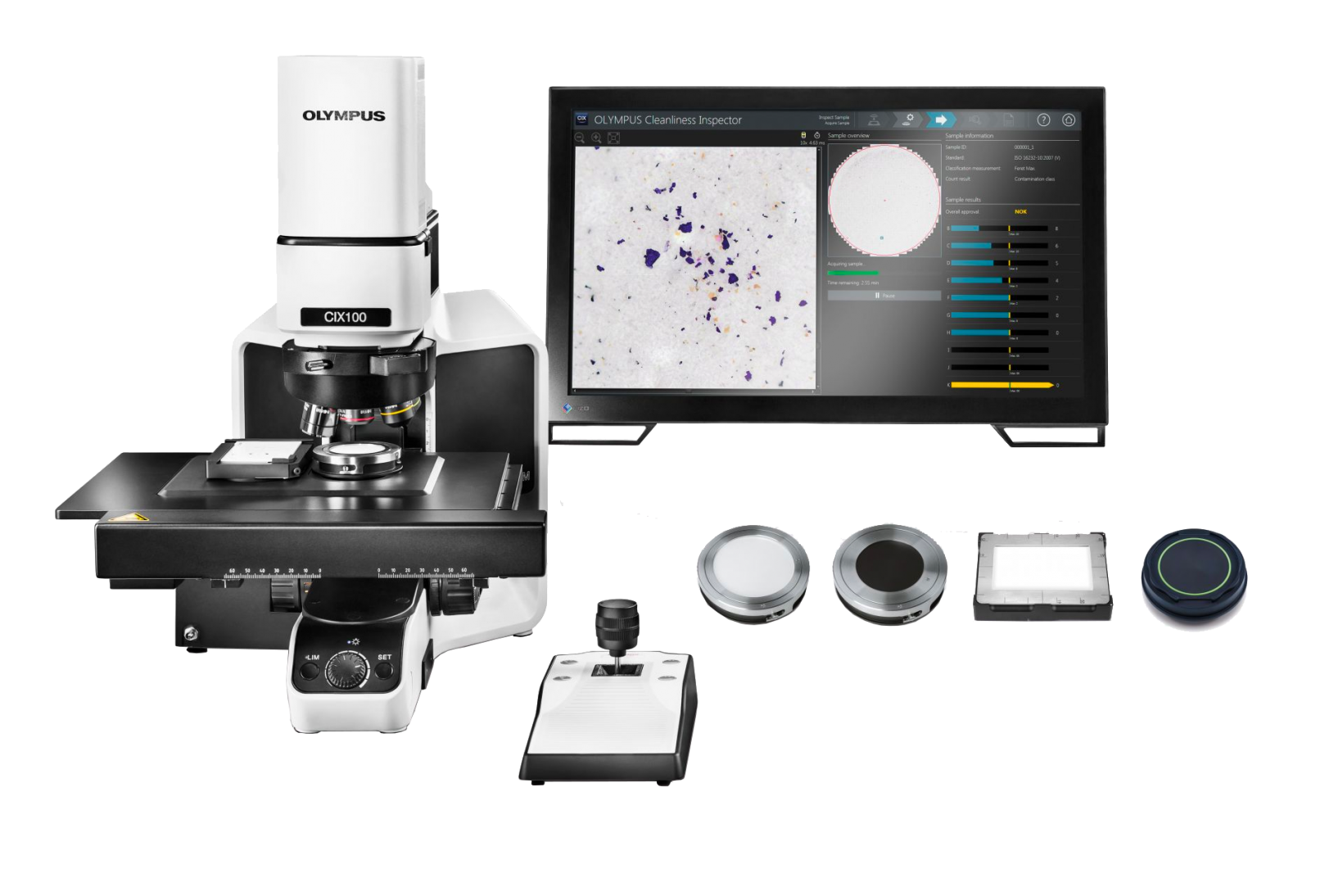

XY motorized stage

| - Joystick operation and control by software

- Inspection of circular and rectangular sample areas

- Automatic or manual repositioning on selected particles

|

|

Motorized nosepiece

| - Selection by software only

|

|

Motorized focusing

| - Control by joystick

- Software autofocus available

- Predictive autofocus using multipoint focus map

|

|

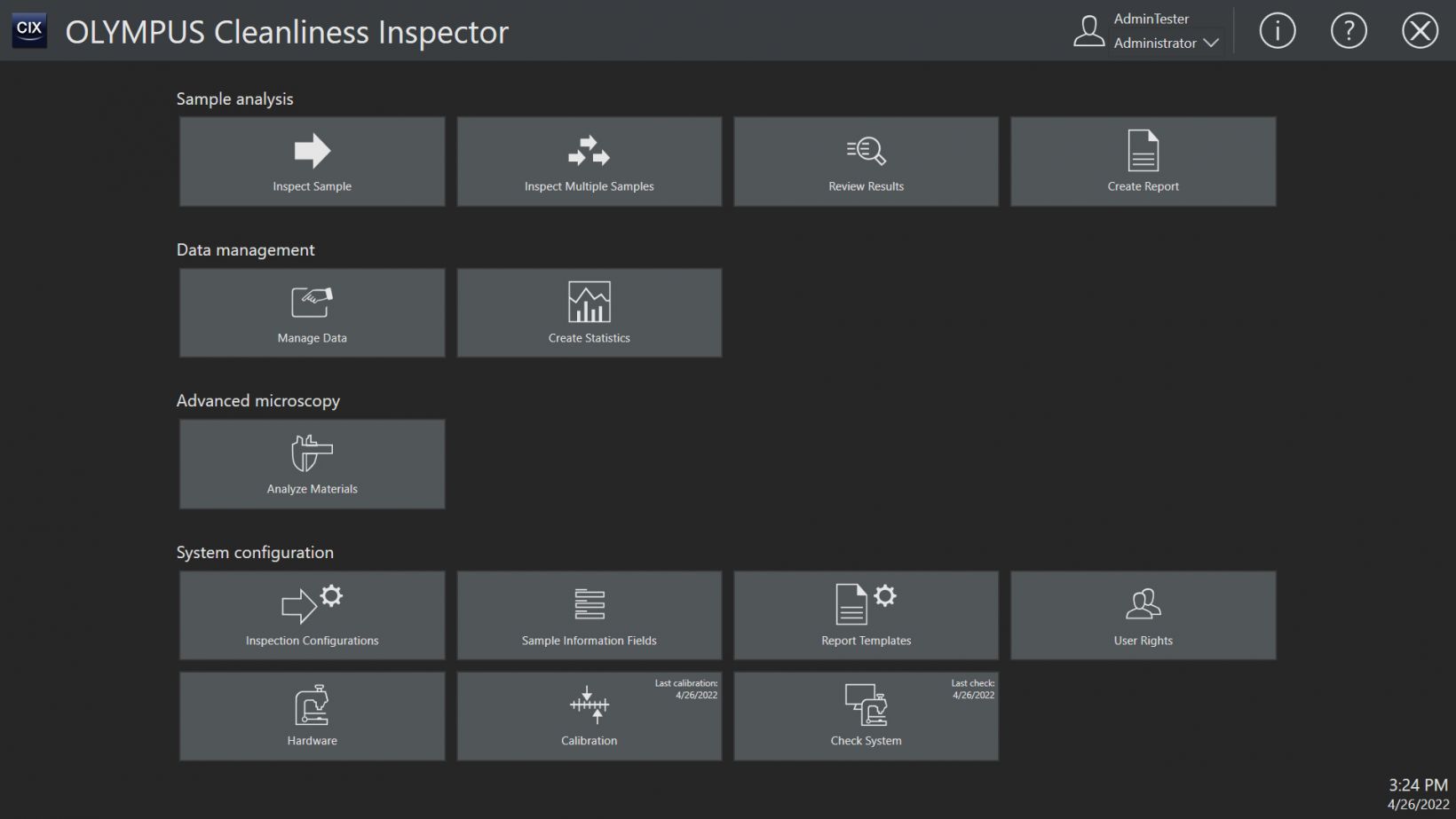

Check system

|

System verification

| - System is verified by measuring the particle standard device parameters

- OK or NOK quality value is produced

|

|

Selectable objective

| - Check system can be performed only with the working objective (one objective should be selected at least)

- Check system is performed with either 5X or 10X objectives (or both)

|

|

Technical cleanliness standards

|

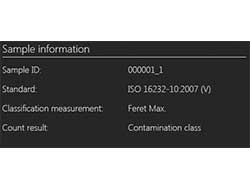

Supported standards

| - ASTM E1216-11:2016; ISO 4406:2021; ISO 4407:1999; ISO 4407:2002 [Cumulative and Differential]; ISO 11218:2017; ISO 12345:2013; ISO 14952:2003; ISO 16232-10:2007 (A, N, and V); ISO 16232:2018 (A, N, and V); ISO 21018:2008; DIN 51455:2020 [70%and 85%]; NAS 1638:1964; NF E 48-651:1986; NF E 48-655:1989; SAE AS4059:2020; VDA 19.1:2015 (A, N, and V); VDA 19.2:2015; VDI 2083-21

|

|

Precisely compliant to VDA19:2016 recommendations

| - Thresholds are automatically set at the VDA recommend values

|

|

Identification of particle family

| - Particles can be classified by particle families (fibers, reflecting, reflecting fibers, or others)

- Possibility to discriminate the detected particles in terms of particle type based on AI

|

|

Customized standards

| - User-defined standards can be easily defined

- Particle measurement parameters include filiform particle size and compact particle size according to DT 55-83

|

|

Inspection configuration

| - The system enables users to load, define, copy, rename, delete, and save an inspection configuration

- Standards and report templates can also be stored and recalled

- It is possible to invert the detection threshold to detect bright particles on a dark background

- It is possible to acquire several samples in a sequence

- It is possible to set approval limits for individual particle types

- It is possible to extend contamination class codes (CCCs) for the different particle types

- Each sample can be inspected with a particular configuration

|

|

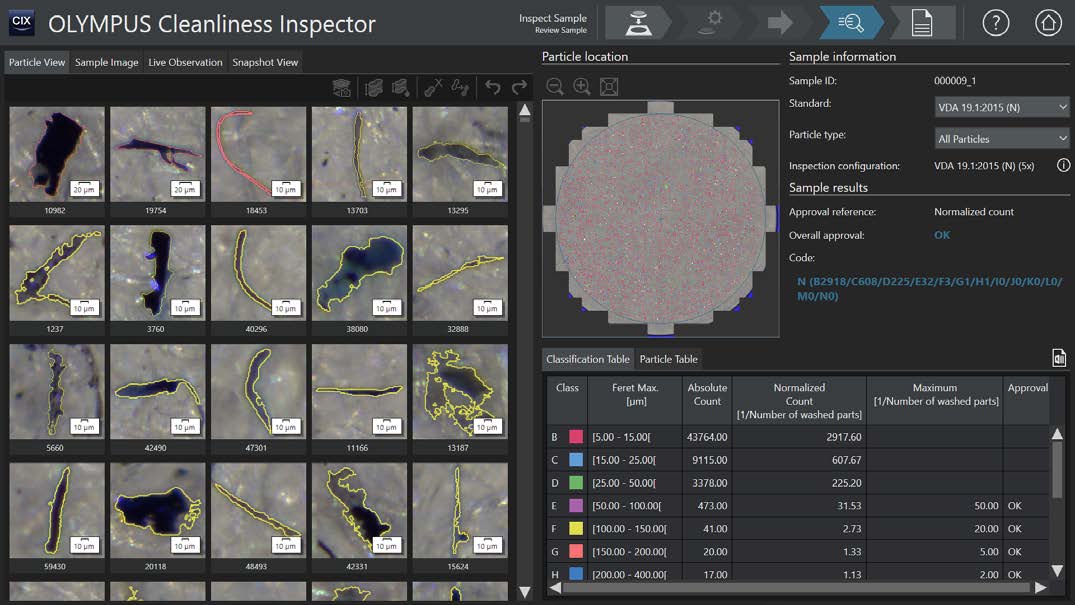

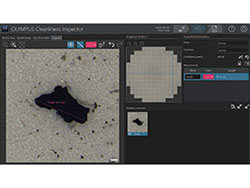

Particle tile view

|

Displays the detected particles in tile for improved navigation

| - Every particle position can be retrieved by double clicking on the tile

- Each tile is adapted to the actual particle size

|

|

Store the full membrane

|

The complete filter is stored

| - Offline analysis enables users to select a different standard for the results display

|

|

Data export

|

Save data

| - Inspection data can be exported to an Excel (.xlsx) table

- All tables available in the software can also be exported into Excel

|

|

Trend analysis

|

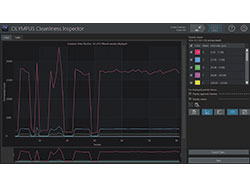

Trend analysis over several samples (built-in SQC tool)

| - Data per size classes can be displayed

- Data can be plotted over time, sample, and measurement ID

- Scale can be selected (log-normal, log-log)

- Data points can be extracted and exported to a spreadsheet

- Table can be exported in Q-DAS (.dfq) format; all tables available in the software can also be exported into Excel

|

|

Particle editing

|

Particles can be edited during the revision process.

|

It is possible to:

- Add, delete, merge, or split particles with lines or a polyline

- Change the particle type

|

|

Dynamic reports

|

Professional analytical reports can be produced using Microsoft Word 2019

| - Templates are customizable

- Users can choose to put the pictures after the table or all pictures grouped together when selecting different particle families

|