概述

Roughness Evaluation ParametersWhat do you do when:

OR

In some cases, no differences can be found between samples using common 3D roughness evaluation parameters such as Sa, Sq, and Sz. When this happens, it can help to focus on other parameters. Here we explain various evaluation parameters in detail with examples demonstrating the purpose for each. |

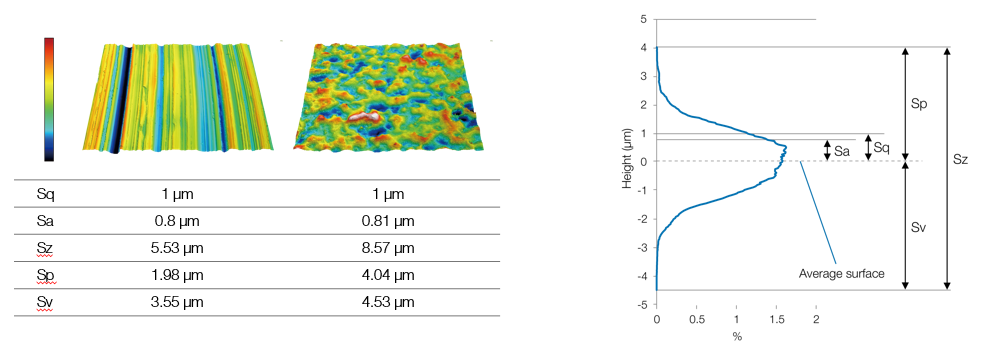

Evaluating the unevenness (Sq, Sa, Sz, Sp, Sv)The unevenness can be evaluated using the height parameter (Sq, Sa, Sz, Sp, and Sv). Within the histogram, height parameters have a relationship as indicated below. Sq (squared mean height) is equivalent to the standard deviation of height distribution and is an easy-to-handle statistical parameter. Sa (arithmetic mean height) is the mean difference in height from the mean plane. When the distribution height is normal, the relationship between the parameters Sq and Sa becomes Sa≒0.8*Sq. As the parameters Sz, Sq, and Sv utilize maximum and minimum height values, the stability of the results may be adversely affected by measurement noise. Height parameter is determined solely by the distribution of height information. Accordingly, the characteristics of horizontal features are not reflected in these parameters.

Application Note: Copper Foil Surface Roughness for 5G Printed Circuit Boards |

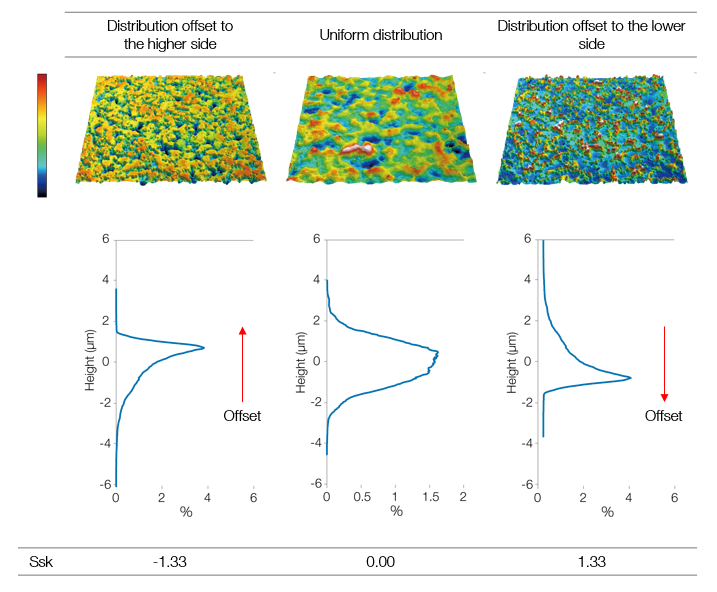

Evaluating the height distribution (Ssk, Sku, histogram)The height distribution is generally evaluated in the form of histogram charts. Ssk is a parameter used in the evaluation of the degree of asymmetry in the graphic representation (distribution) of the histogram chart. Ssk = 0 signifies that the difference in height is distributed uniformly, while minus values of the parameter indicate a deviation to the higher side and plus indicates a deviation to the lower side. In samples with the higher features whittled away due to sliding abrasion, Ssk values tend to indicate negative values. Because of this, the parameter is sometimes used as an evaluation index for the extent of sliding abrasion.

|

Evaluating the fineness (Sal, Sdq, Sdr)The Sal parameter provides a numerical index of the density of similar structures in units of length. Features become finer as the value gets smaller. Indirect indices representing the fineness of features include local gradients and the superficial area. Sdq is the mean value of local gradients present on the surface, while Sdr is a parameter indicating the rate of growth in the superficial area. If height parameters such as Sa and Sq are on a comparable level, the degree of fineness becomes finer as parameters Sdq (gradient) and Sdr (superficial area) become larger.

Application Note: Copper Foil Surface Roughness for 5G Printed Circuit Boards |

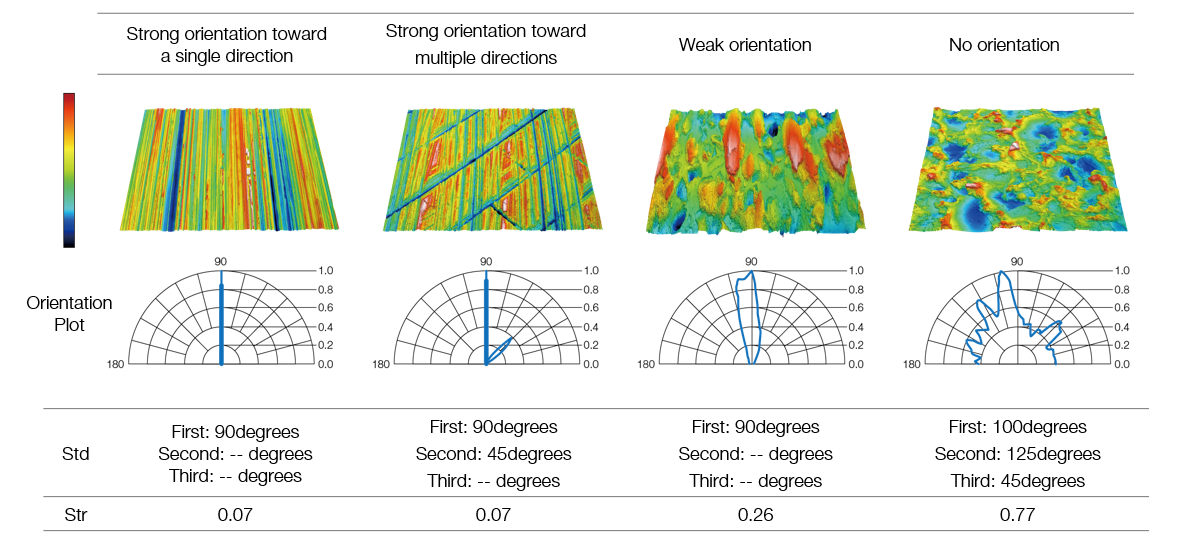

Evaluating the orientation (Std, Str, directional plotting)The orientation plot represents the directional properties of surface features as an angular chart. Plotted peaks become sharper as the orientation becomes pronounced. The strength of orientation is normalized, so the strongest peak is in contact with the outermost circle. Within an orientation plot, the Std parameter indicates the angle of peaks sequentially from the largest peak. The Str parameter is a numerical representation of the strength of orientation. Str<0.3 signifies a (directional) anisotropic surface, while Str>0.5 represents an isotropic surface.

|

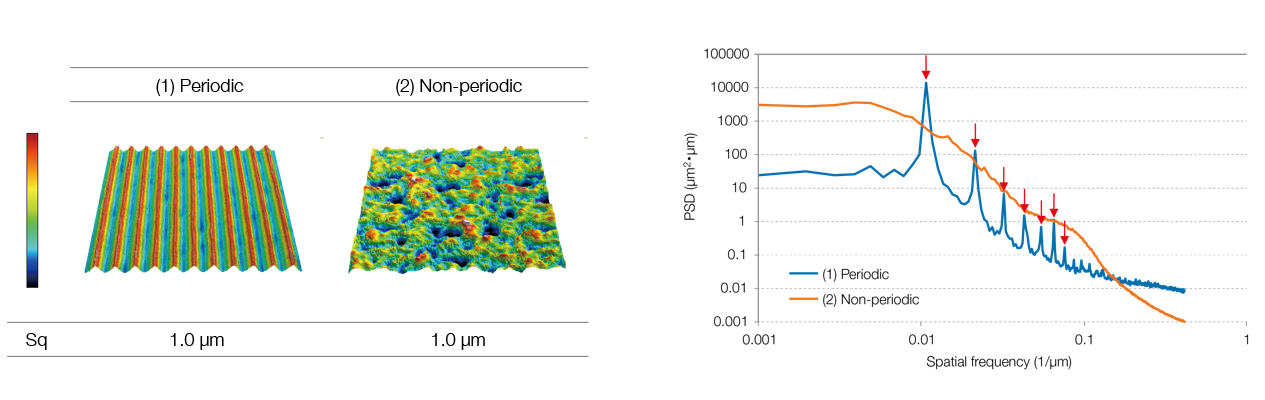

Evaluating the periodicity (PSD)Power spectral density (PSD) represents the magnitude of surface unevenness for the respective spatial frequency. In samples with periodicity, peaks (arrows) are present in the PSD chart. The frequency of the periodicity (inverse number of the cycle) can be obtained by determining the horizontal axis of the peak. The chart shows a general decline to the right if no periodicity is present.

|

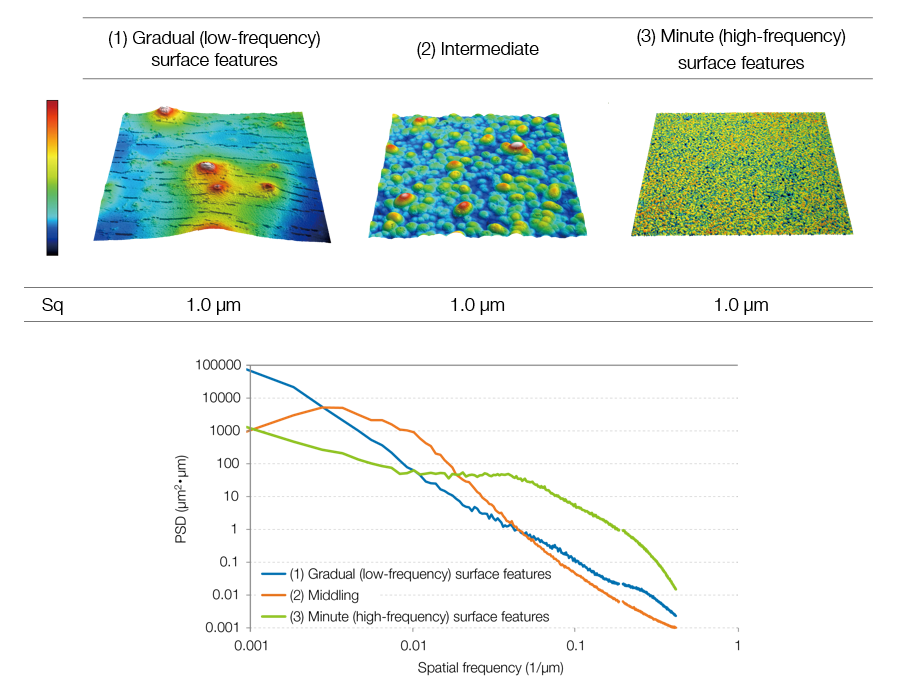

Evaluating the dominant feature component (PSD)Power spectral density (PSD) represents the magnitude of surface unevenness for the respective spatial frequencies: gradual and minute. Similar feature characteristics are reflected in the PSD charts. In gradual surface features, the values on the low-frequency end (left side of the chart) tend to be larger. In minute surface features, the values on the high-frequency end (right side of the chart) tend to be larger.

|

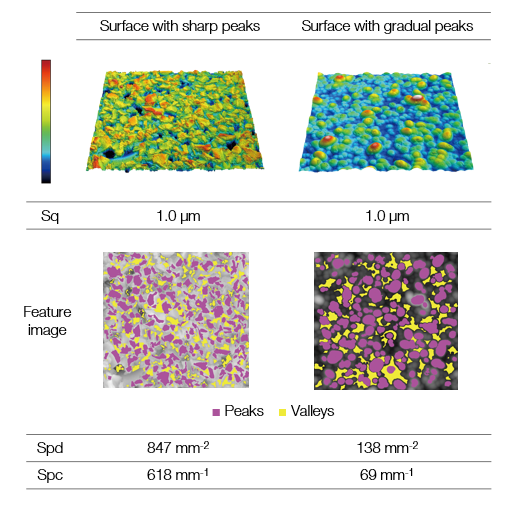

Evaluating the quantity and tip configuration of peaks (Spd, Spc)Peaks present on the surface relate to the osculation of objects, friction, abrasion, and similar phenomena. The feature image indicates the categorized topographical characteristics (peaks, valleys, ridge lines, and channel lines) of the surfaces. The Spd parameter represents the density (number of features per unit area) of surface features categorized into peaks (colored pink) within the feature image. The Spc parameter represents the mean curvature radius of peaks for surface features categorized into peaks within the feature image. As the Spc value becomes larger, the curvature of peaks grow smaller (sharper), and the curvature increases (obtuse) as the value gets smaller.

|

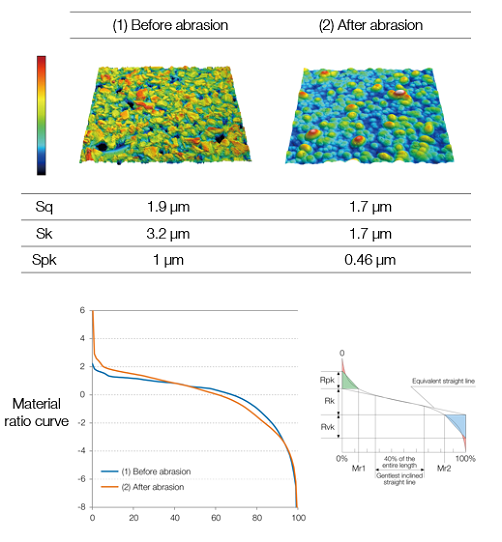

Evaluating the variation before/after abrasion (Sk, Spk, Svk)Generally, abrasion progresses from the surface’s highest position. The use of height distribution based parameters is effective in the evaluation of abrasion status. With the progress of abrasion, the curve in the higher portion of the material ratio curve moves downward, while the curve on the lower portion shifts upward. The values for the parameters Sk and Spk decline in correspondence with the progress of abrasion.

|